The two primary methods for producing PTFE sliding bearing pads concern how the PTFE plate is bonded to the rubber bearing. The first method involves creating the rubber bearing and the dimpled PTFE plate as separate components and then bonding them together. The second, more integrated method, forms the dimples in the PTFE plate during the vulcanization process of the rubber bearing itself.

The critical distinction in bearing pad production is not about creating the raw PTFE material, but about the specific assembly process used to integrate the PTFE slide plate with the elastomeric bearing. This choice directly influences manufacturing complexity, bond integrity, and overall cost.

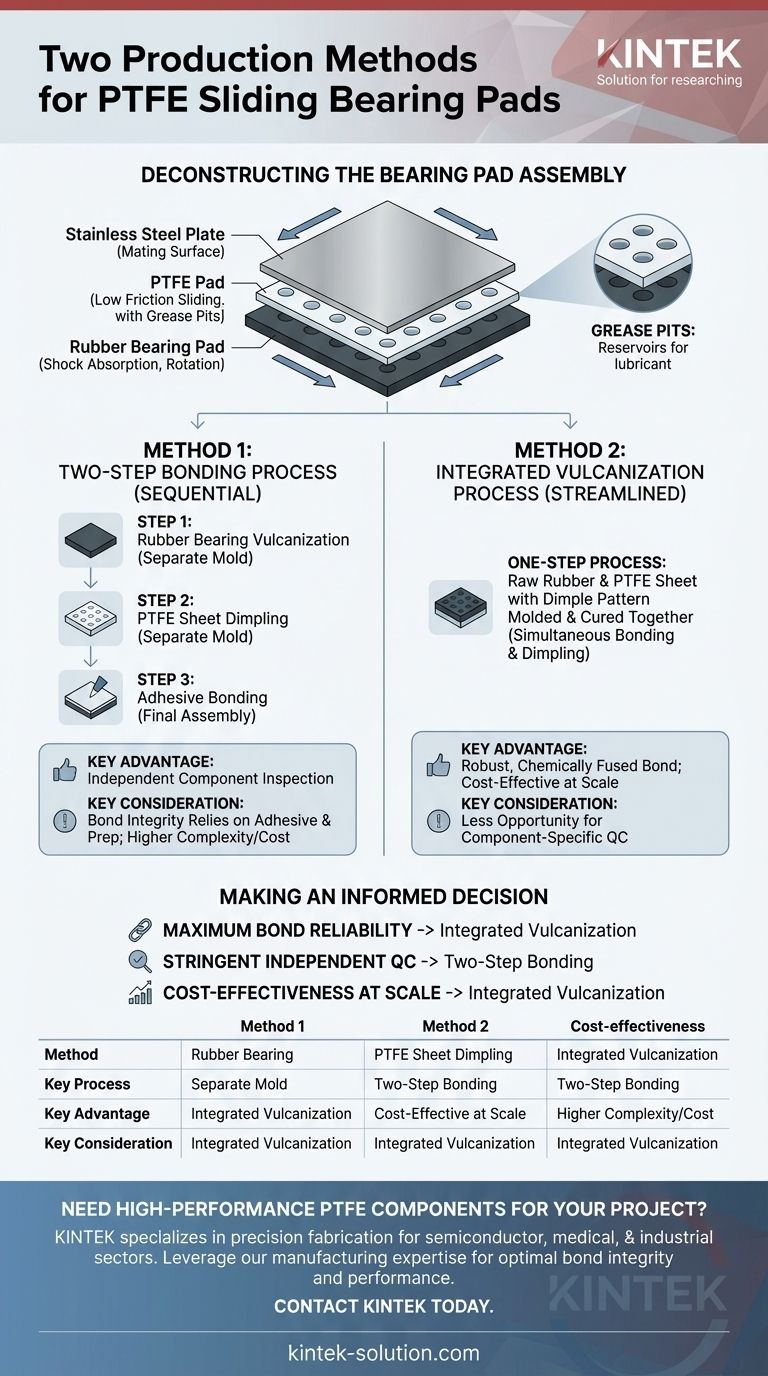

Deconstructing the Bearing Pad Assembly

To understand the manufacturing methods, we must first understand the components and their functions. A typical PTFE sliding bearing pad is a composite structure, not a single material.

The Core Components

A complete sliding bearing assembly consists of three key parts.

The rubber bearing pad provides shock absorption and buffering. It accommodates rotation and vertical loads while reducing vibration and noise.

The PTFE pad is bonded to the top of the rubber pad. Its extremely low coefficient of friction is what allows for the sliding movement necessary to accommodate thermal expansion and contraction.

A stainless steel plate is the mating surface that slides against the PTFE. It is attached to the opposing structural element and provides a smooth, durable, and corrosion-resistant surface.

The Role of Grease Pits

The surface of the PTFE pad is not flat; it is intentionally pressed with a pattern of small dimples or "grease pits."

These pits act as reservoirs for silicone grease. This lubricant is essential for maintaining the pad's low-friction properties over the decades-long service life of the structure.

The Two Core Manufacturing Philosophies

The two production methods diverge in how and when these grease pits are formed and how the PTFE is attached to the rubber.

Method 1: The Two-Step Bonding Process

This is a sequential assembly method.

First, the rubber bearing is produced through its own vulcanization process. Separately, a pre-fabricated sheet of PTFE is placed into a dedicated mold and pressed to form the required pattern of grease pits.

Finally, the finished rubber bearing and the finished (dimpled) PTFE plate are bonded together using a specialized adhesive. This is a distinct, final assembly step.

Method 2: The Integrated Vulcanization Process

This method streamlines the production by combining steps.

In this process, the flat PTFE sheet is placed directly into the mold along with the raw rubber. During the rubber vulcanization cycle—the process of curing the rubber with heat and pressure—a patterned plate presses the grease pits into the PTFE.

Simultaneously, the heat and pressure of vulcanization bond the PTFE sheet directly to the rubber bearing, creating a single, integrated component in one operation.

Understanding the Trade-offs

Neither method is inherently superior in all situations; they represent different approaches with distinct advantages and disadvantages.

Complexity and Cost

The Two-Step Process requires an extra mold specifically for pressing the PTFE plate and involves a separate bonding step. This can add to the complexity and overall cost of production.

The Integrated Process is more efficient. It eliminates the need for a separate PTFE mold and the subsequent bonding stage, which can lower manufacturing costs, especially at high volumes.

Bond Integrity

Bonding is a critical failure point. In the Integrated Process, the vulcanization creates a powerful chemical and mechanical bond between the rubber and the PTFE. This is often considered a more robust and reliable bond.

With the Two-Step Process, the quality of the bond is entirely dependent on surface preparation and the adhesive used. While highly effective when done correctly, it introduces another variable that must be rigorously controlled.

A Common Point of Confusion: Pad Assembly vs. Raw Material

It is crucial to distinguish between the assembly of the bearing pad and the production of the raw PTFE material itself.

Producing the Raw PTFE

The references to suspension polymerization and dispersion polymerization describe how the PTFE polymer is chemically created from its monomer gas.

Suspension polymerization creates PTFE grains that are processed into solid pellets, which are then used to mold or extrude the sheets needed for bearing pads. Dispersion polymerization creates a finer powder typically used for coatings.

Fabricating the PTFE Sheet

Once the raw PTFE is created, it is formed into large sheets or blocks. These are then cut to the required dimensions for the bearing pad using methods like die cutting, water jet cutting, or stamping before being used in either of the two assembly processes.

Making an Informed Decision

Your choice of specification should depend on the project's priorities.

- If your primary focus is maximum bond reliability: The integrated vulcanization method is often preferred as it typically creates a more robust, chemically fused bond between the layers.

- If your primary focus is stringent, independent quality control: The two-step method allows for the rubber pad and the PTFE plate to be inspected and qualified as separate components before the final bonding.

- If your primary focus is cost-effectiveness at scale: The integrated vulcanization process is generally more efficient, eliminating steps and potentially lowering the final unit cost.

Understanding these manufacturing nuances allows you to specify the right bearing pad that aligns with your project's specific performance, quality, and budgetary requirements.

Summary Table:

| Method | Key Process | Key Advantage | Key Consideration |

|---|---|---|---|

| Two-Step Bonding | PTFE plate is dimpled and bonded to finished rubber bearing as a separate step. | Allows for independent inspection of components before final assembly. | Bond integrity relies on adhesive quality and surface preparation. |

| Integrated Vulcanization | PTFE is dimpled and bonded to the rubber during the rubber's vulcanization process. | Creates a robust, chemically fused bond; more cost-effective at scale. | A single-step process with less opportunity for component-specific QC. |

Need high-performance PTFE components for your project?

The manufacturing method you choose directly impacts the performance and longevity of your PTFE sliding bearing pads. At KINTEK, we specialize in the precision fabrication of PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors.

We understand these critical manufacturing nuances and can help you select the right process for your specific requirements, whether you need prototypes or high-volume orders. Our expertise ensures optimal bond integrity, dimensional accuracy, and material performance.

Contact KINTEK today to discuss your PTFE component needs and leverage our manufacturing expertise for your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What temperature range can PTFE rods withstand? From -200°C to +260°C for Extreme Versatility

- What are some common configurations of Teflon back-up rings? Achieve Superior O-Ring Support and Extrusion Resistance

- What are some common types of PTFE seals? Choose the Right Seal for Static or Dynamic Applications

- What are the key material properties of PTFE that make it suitable for expansion joints? Ensure Long-Term Reliability in Demanding Systems

- What industries and applications commonly use piston seals? From Heavy Construction to Medical Devices

- What challenges are associated with machining Teflon and how are they addressed? Master Precision PTFE Manufacturing

- What is PTFE and why is it used for seals? The Ultimate Guide to High-Performance Sealing

- Where are PTFE energized seals typically used in cryogenic applications? Critical Seals for LNG & Aerospace