Spring-energized PTFE seals are available in three primary load ratings: light, medium, and heavy. These ratings are not arbitrary; they define the amount of force the internal spring exerts on the seal lips, which is a critical factor in determining the seal's performance, friction, and operational lifespan.

The selection of a spring load rating is a fundamental engineering trade-off. You are balancing the need for a robust sealing barrier against the equally important goals of minimizing friction, wear, and energy consumption.

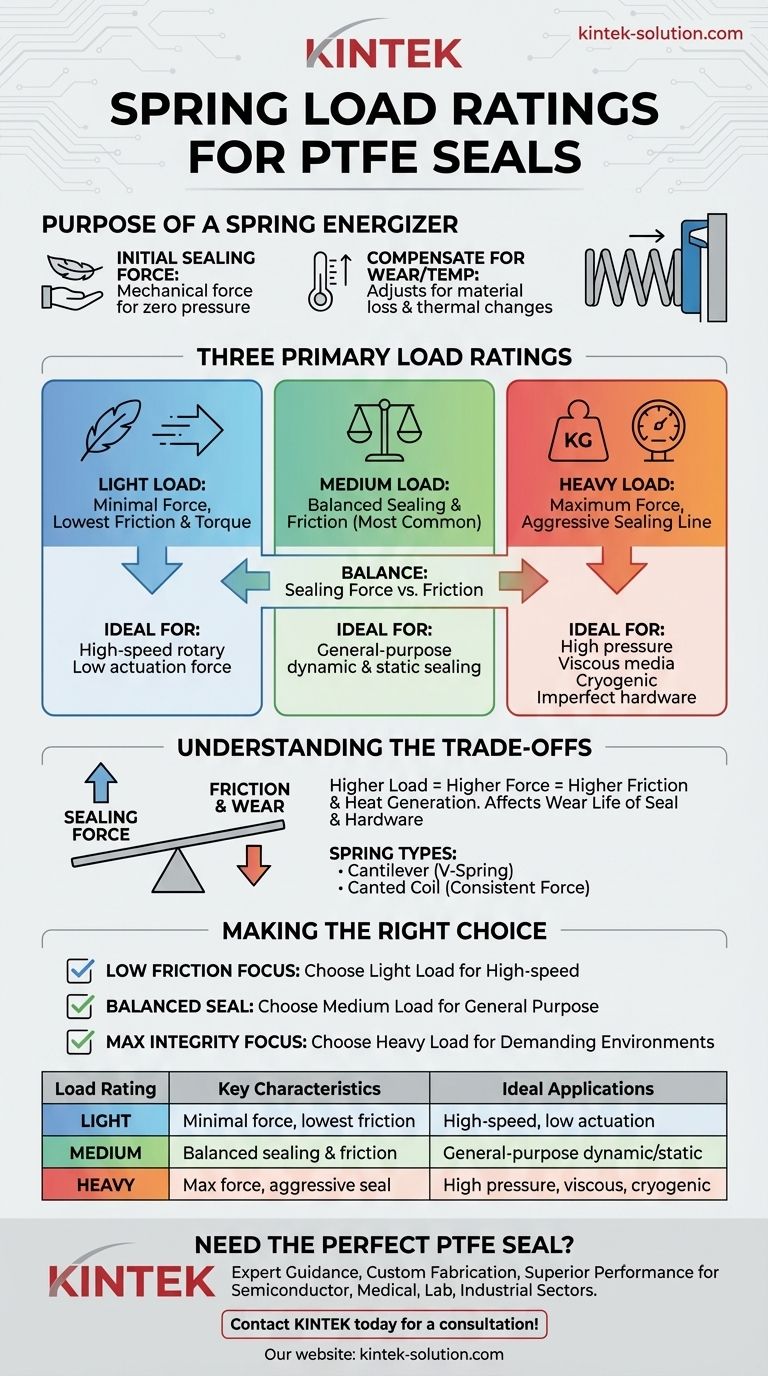

The Purpose of a Spring Energizer

Polytetrafluoroethylene (PTFE) is a remarkable material known for its low friction and chemical inertness, but it lacks the natural elasticity of rubber. The internal metallic spring is what gives the seal its resilience.

Providing Initial Sealing Force

At low pressures, the system media may not be forceful enough to press the seal lips against the hardware. The spring provides the initial mechanical force necessary to create a positive seal from zero pressure upwards.

Compensating for Wear and Temperature

Over the seal's life, the PTFE jacket will inevitably wear down. The spring constantly adjusts, pushing the seal lips outward to compensate for this material loss and maintain a consistent sealing line. It also adapts to thermal expansion and contraction across wide temperature ranges, from cryogenic to high-heat applications.

Defining the Spring Load Ratings

Each load rating is designed for a different set of operational demands. The choice directly influences the contact pressure, or "lip load," at the sealing interface.

Light Load

A light-load spring exerts the least amount of force. It is specified for applications where minimizing friction and torque is the highest priority.

This is ideal for dynamic rotary applications with high speeds or in equipment where actuation force must be kept to an absolute minimum.

Medium Load

The medium-load spring is the most common and versatile option. It offers a robust balance between good sealing capability and reasonable friction and wear characteristics.

This is the standard starting point for a wide range of general-purpose dynamic and static sealing applications.

Heavy Load

A heavy-load spring provides the highest sealing force. This creates a highly concentrated and aggressive sealing line capable of handling more demanding conditions.

It is used for sealing high-viscosity media, in high-pressure gas service, or in applications with potential hardware imperfections where extra force is needed to ensure a leak-free barrier.

Understanding the Trade-offs

Choosing a spring load is never done in isolation. A gain in one performance area often comes at a cost in another.

Sealing Force vs. Friction

The core trade-off is simple: higher spring load creates higher sealing force, but also higher friction. This increased friction translates directly into greater energy consumption and heat generation in dynamic applications.

Wear Life

Higher friction from heavy-load springs will accelerate the wear of the PTFE seal jacket. More critically, it can also lead to increased wear on the mating hardware surface, which can be far more costly to repair or replace.

Spring Types

The type of spring, such as a cantilever (V-spring) or a canted coil spring, also influences performance. Canted coil springs, for example, can offer a more consistent force across a wider range of deflection, which can be beneficial in applications with significant hardware tolerances or wear.

Making the Right Choice for Your Application

Your application's specific requirements must guide your selection. Consider the following recommendations as a starting point.

- If your primary focus is minimizing friction for high-speed or sensitive equipment: Your best choice is a light-load spring to reduce drag and heat generation.

- If your primary focus is a balanced, general-purpose seal for standard conditions: A medium-load spring provides a reliable seal without generating excessive friction.

- If your primary focus is maximum sealing integrity in a demanding environment (high pressure, viscous fluids, or cryogenic): A heavy-load spring is required to ensure a robust and reliable barrier.

Ultimately, selecting the correct spring load ensures your seal performs effectively for its intended lifespan.

Summary Table:

| Spring Load Rating | Key Characteristics | Ideal Applications |

|---|---|---|

| Light Load | Minimal force, lowest friction & torque | High-speed rotary, low actuation force |

| Medium Load | Balanced sealing force & friction (most common) | General-purpose dynamic & static sealing |

| Heavy Load | Maximum sealing force, aggressive sealing line | High pressure, viscous media, cryogenic, imperfect hardware |

Need the Perfect PTFE Seal for Your Application?

Choosing the correct spring load is critical for performance and longevity. The experts at KINTEK specialize in manufacturing precision PTFE components—including custom spring-energized seals—for the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Expert Guidance: Help you select the optimal spring load (light, medium, or heavy) for your specific pressure, speed, and media requirements.

- Custom Fabrication: From prototypes to high-volume orders, we tailor seals to your exact specifications.

- Superior Performance: Achieve the ideal balance of sealing integrity, low friction, and long service life.

Let's optimize your sealing solution. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What makes PTFE gaskets suitable for aerospace applications? Unmatched Reliability in Extreme Conditions

- What types of fasteners and custom parts can be made from Teflon (PTFE)? Explore Its Unique Advantages

- What makes PTFE envelope gaskets appropriate for food and pharmaceutical applications? Ensure Purity and Compliance

- Why is Teflon difficult to machine to tight tolerances? Overcome Material Instability

- What are the key features and benefits of PTFE bushings? Achieve Maintenance-Free Operation in Demanding Environments

- What are the aerospace applications of precision-machined PTFE parts? Achieve Peak Performance in Harsh Environments

- What is the load bearing capacity of PTFE wear plates? Strength Meets Low Friction for Heavy Loads

- What advantage does the low coefficient of friction of PTFE balls provide? Boost Durability and Efficiency