At its core, the advantage of the low coefficient of friction in PTFE balls is a dramatic reduction in wear and tear on moving parts. This single property leads directly to smoother, more reliable operation over long periods and significantly extends the service life of the components they are used in.

The true value of PTFE's low friction is not simply that it's "slippery," but how that characteristic translates into tangible engineering outcomes: enhanced durability, greater energy efficiency, and a lower risk of mechanical failure.

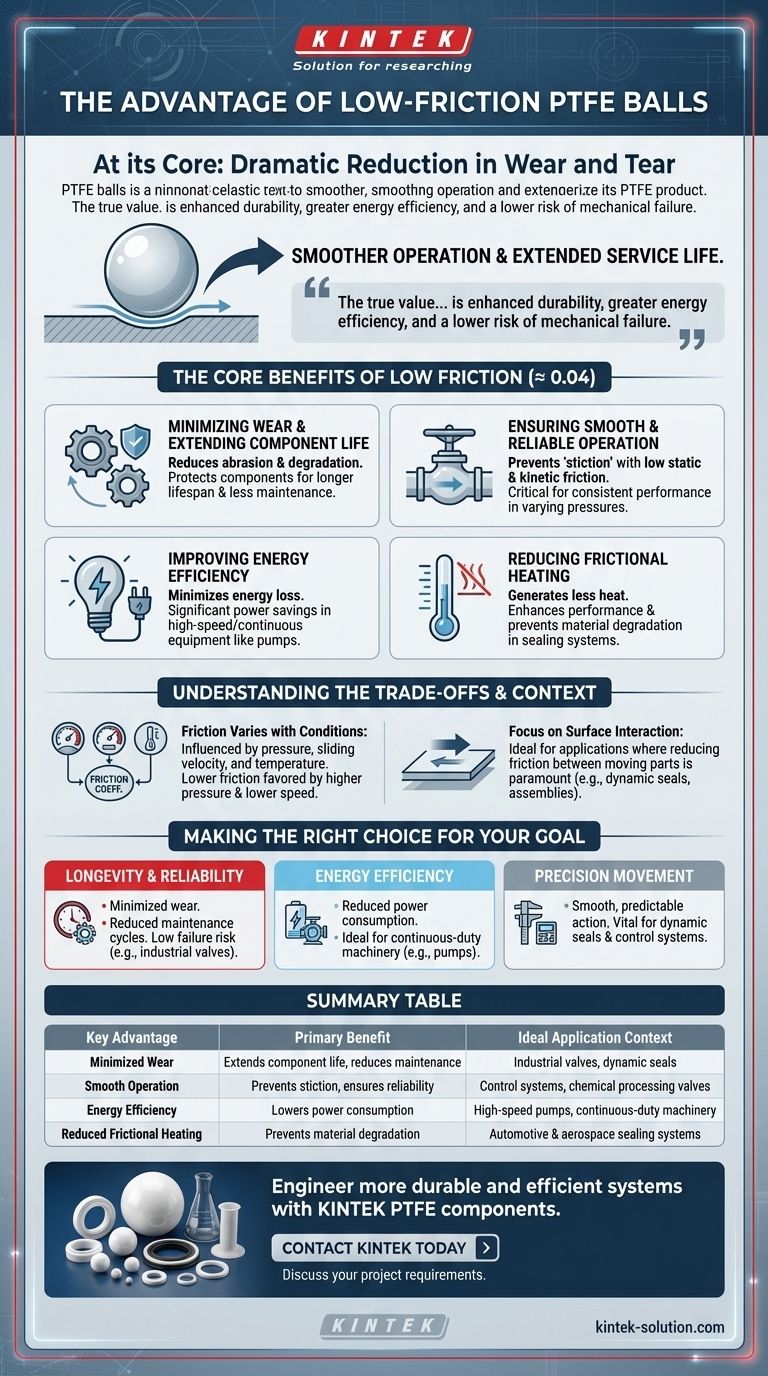

The Core Benefits of Low Friction

PTFE's exceptionally low friction coefficient, around 0.04, is a defining feature that provides several distinct advantages in mechanical systems. This is significantly lower than even lubricated steel, which has a kinetic friction coefficient of 0.05.

Minimizing Wear and Extending Component Life

When components slide against each other, friction causes abrasion and material degradation.

PTFE's low-friction surface minimizes this wear, protecting both the ball and the surrounding parts. This directly results in a longer operational lifespan and reduces the need for frequent maintenance or replacement.

Ensuring Smooth and Reliable Operation

Friction can cause parts to stick or move erratically. Because PTFE has an extremely low coefficient for both static and kinetic friction, it prevents this "stiction."

This ensures components move smoothly and predictably, which is critical in applications like valves in chemical processing plants that must operate reliably under varying pressures.

Improving Energy Efficiency

Every mechanical system loses some energy to friction. By minimizing this resistance, PTFE reduces the amount of energy required to operate the system.

In high-speed or continuous-use equipment like pumps, this reduction in wasted energy can lead to significant power savings and improved overall efficiency.

Reducing Frictional Heating

Friction is a primary source of heat in dynamic, or moving, applications. Excessive heat can cause materials to degrade, warp, or fail prematurely.

PTFE’s low friction generates far less heat, enhancing its performance and integrity, especially when used as a sealing material in automotive or aerospace systems.

Understanding the Trade-offs and Context

While incredibly beneficial, the low friction of PTFE is not a static property. Its effectiveness is influenced by the operational environment, and it's important to understand these factors.

Friction Varies with Conditions

The coefficient of friction in PTFE is not a single, constant number. It is influenced by variables such as pressure, sliding velocity, and temperature.

Generally, lower friction values are favored by higher pressure and lower sliding speeds. This context is critical for designing an application to take full advantage of the material's properties.

The Focus is on Surface Interaction

The primary benefit of PTFE balls comes from their surface properties. This makes them ideal for applications where reducing friction between moving parts is the main objective.

This focus is why they are so prevalent in dynamic sealing applications and as components within larger mechanical assemblies where smooth movement is paramount.

Making the Right Choice for Your Goal

Leveraging PTFE effectively means matching its low-friction properties to your primary engineering objective.

- If your primary focus is longevity and reliability: The key benefit is minimized wear, which reduces maintenance cycles and lowers the risk of failure in critical components like industrial valves.

- If your primary focus is energy efficiency: The advantage lies in reducing operational power consumption, especially in continuous-duty or high-speed machinery like pumps and impellers.

- If your primary focus is precision movement: PTFE’s consistently low static and kinetic friction ensures smooth, predictable action, which is vital for dynamic seals and control systems.

Ultimately, understanding this fundamental property of PTFE allows you to engineer more durable, efficient, and reliable mechanical systems.

Summary Table:

| Key Advantage | Primary Benefit | Ideal Application Context |

|---|---|---|

| Minimized Wear | Extends component life, reduces maintenance | Industrial valves, dynamic seals |

| Smooth Operation | Prevents stiction, ensures reliability | Control systems, chemical processing valves |

| Energy Efficiency | Lowers power consumption | High-speed pumps, continuous-duty machinery |

| Reduced Frictional Heating | Prevents material degradation | Automotive & aerospace sealing systems |

Engineer more durable and efficient systems with KINTEK PTFE components.

Our precision-manufactured PTFE balls, seals, and custom labware are designed to leverage these low-friction advantages in your specific application—whether in semiconductor, medical, laboratory, or industrial equipment. We partner with you from prototype to high-volume production to ensure optimal performance and longevity.

Contact KINTEK today to discuss your project requirements and discover the right PTFE solution for your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials