To be direct, you can fabricate a wide range of common fasteners from Teflon (PTFE), including screws, hex nuts, hex head cap screws, and flat washers. Beyond these standard components, its unique properties and machinability make it an excellent material for an extensive variety of custom-designed parts.

The critical insight is not what can be made from Teflon, but why you would choose it. Teflon is selected for its extraordinary performance in extreme environments—where its chemical inertness, temperature stability, and low-friction surface are necessary and conventional materials would fail.

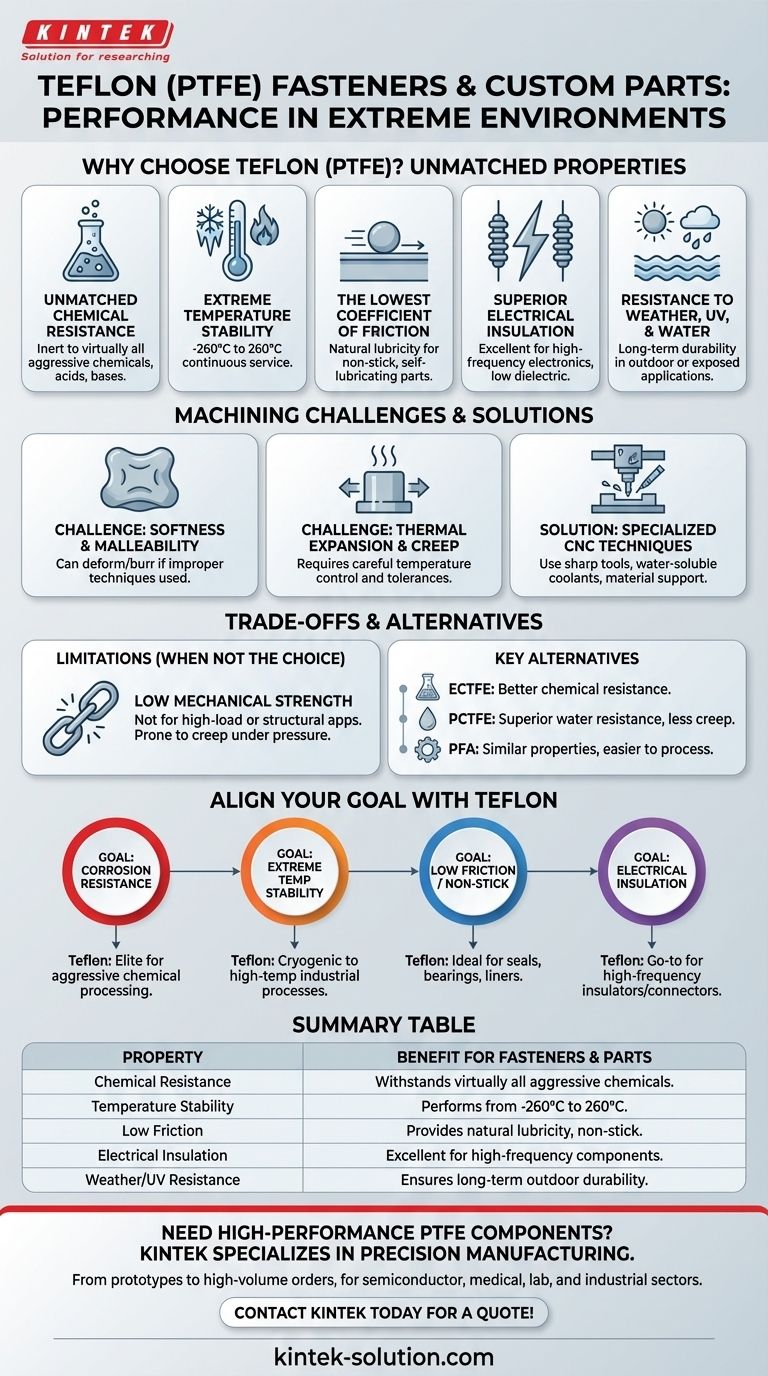

Why Choose Teflon (PTFE) for Your Components?

Choosing a material is about matching its properties to the demands of the application. Teflon is a specialized polymer used when standard plastics or metals are unsuitable.

Unmatched Chemical Resistance

Teflon is renowned for its exceptional corrosion resistance. It is virtually inert to almost all industrial chemicals, acids, and bases, making it indispensable for components used in chemically aggressive environments.

Extreme Temperature Stability

This material performs reliably across a vast temperature range, from cryogenic conditions at -260°C (-436°F) up to a continuous service temperature of 260°C (500°F). This stability ensures parts do not become brittle or deform under thermal stress.

The Lowest Coefficient of Friction

Often called the "slipperiest" solid material, Teflon has an extremely low coefficient of friction. This creates a natural lubricity, making it ideal for self-lubricating bearings, seals, and any application where smooth movement and non-stick surfaces are critical.

Superior Electrical Insulation

Teflon possesses excellent electrical insulating properties, including a low dielectric constant and dissipation factor. This makes it a premier choice for manufacturing insulators, connectors, and other components in high-frequency electronics.

Resistance to Weather, UV, and Water

Components made from Teflon exhibit outstanding resistance to weathering, UV radiation, and water absorption. This ensures long-term durability and performance in exposed or outdoor applications.

The Reality of Machining Teflon Parts

While versatile, Teflon's unique characteristics present specific manufacturing challenges that require specialized knowledge to overcome.

The Challenge of Softness

Teflon's inherent softness and malleability mean it can deform or create burrs during machining if improper techniques are used. It tends to slide away from a cutting tool rather than being cleanly sheared.

Managing Thermal Expansion

The material has a high coefficient of thermal expansion and can "creep" or deform under sustained load. Achieving and maintaining tight tolerances requires careful temperature control during the machining process and an understanding of how the part will behave in its final application.

The Need for Specialized Techniques

Successfully fabricating precise Teflon parts relies on modern CNC machining methods (milling, turning, and drilling). Key factors for success include using extremely sharp cutting tools, applying water-soluble coolants, and providing adequate material support to prevent chatter and deformation.

Understanding the Trade-offs and Alternatives

No material is perfect for every situation. Understanding Teflon's limitations is crucial for making an informed decision.

When Teflon Is Not the Right Choice

Due to its softness, Teflon has relatively low mechanical strength and is not suitable for high-load or structural applications. It is prone to creep under constant pressure, which can be a limitation for certain sealing or fastening jobs.

Key Alternatives to Consider

If Teflon's properties don't perfectly match your needs, other fluoropolymers may be a better fit:

- ECTFE (Ethylene Chlorotrifluoroethylene): Offers even better all-around chemical resistance than PTFE.

- PCTFE (Polychlorotrifluoroethylene): Provides superior water resistance and less creep.

- PFA (Perfluoroalkoxy): Has similar chemical and temperature resistance but is easier to process, though with less abrasion resistance.

Making the Right Choice for Your Goal

To select the right fastener or custom part, align the material's strengths with your primary objective.

- If your primary focus is corrosion resistance: Teflon is an elite choice for fasteners and components in aggressive chemical processing or laboratory equipment.

- If your primary focus is extreme temperature stability: Use Teflon parts in applications ranging from cryogenic systems to high-temperature industrial processes.

- If your primary focus is low friction or a non-stick surface: Teflon is ideal for creating self-lubricating bearings, seals, or liners where preventing adhesion is critical.

- If your primary focus is electrical insulation: It is the go-to material for high-frequency insulators and connectors where signal integrity is paramount.

Ultimately, choosing Teflon is a strategic decision to ensure reliability and performance where other materials simply cannot compete.

Summary Table:

| Property | Benefit for Fasteners & Parts |

|---|---|

| Chemical Resistance | Withstands virtually all aggressive chemicals and solvents. |

| Temperature Stability | Performs from -260°C to 260°C (-436°F to 500°F). |

| Low Friction | Provides natural lubricity for non-stick, self-lubricating parts. |

| Electrical Insulation | Excellent for high-frequency insulators and connectors. |

| Weather/UV Resistance | Ensures long-term durability in outdoor or exposed environments. |

Need high-performance PTFE components that can handle extreme conditions?

KINTEK specializes in the precision manufacturing of custom PTFE parts—from seals and liners to complex labware and fasteners. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering solutions where chemical inertness, temperature stability, and low friction are critical. Our expertise ensures your custom fabrication, from prototypes to high-volume orders, meets the highest standards of quality and reliability.

Contact KINTEK today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech