In the simplest terms, PTFE lined globe valves are primarily used to stop, start, and precisely regulate the flow of fluids in applications where chemical resistance is critical. Their most common uses are found in industrial support systems, including cooling water, fuel oil transportation, and turbine lube oil systems.

A PTFE lined globe valve is not a generic component; it's a specialized solution. It combines the precise throttling capability of a globe valve with the superior chemical inertness of a PTFE liner, making it the go-to choice for regulating the flow of corrosive or high-purity media.

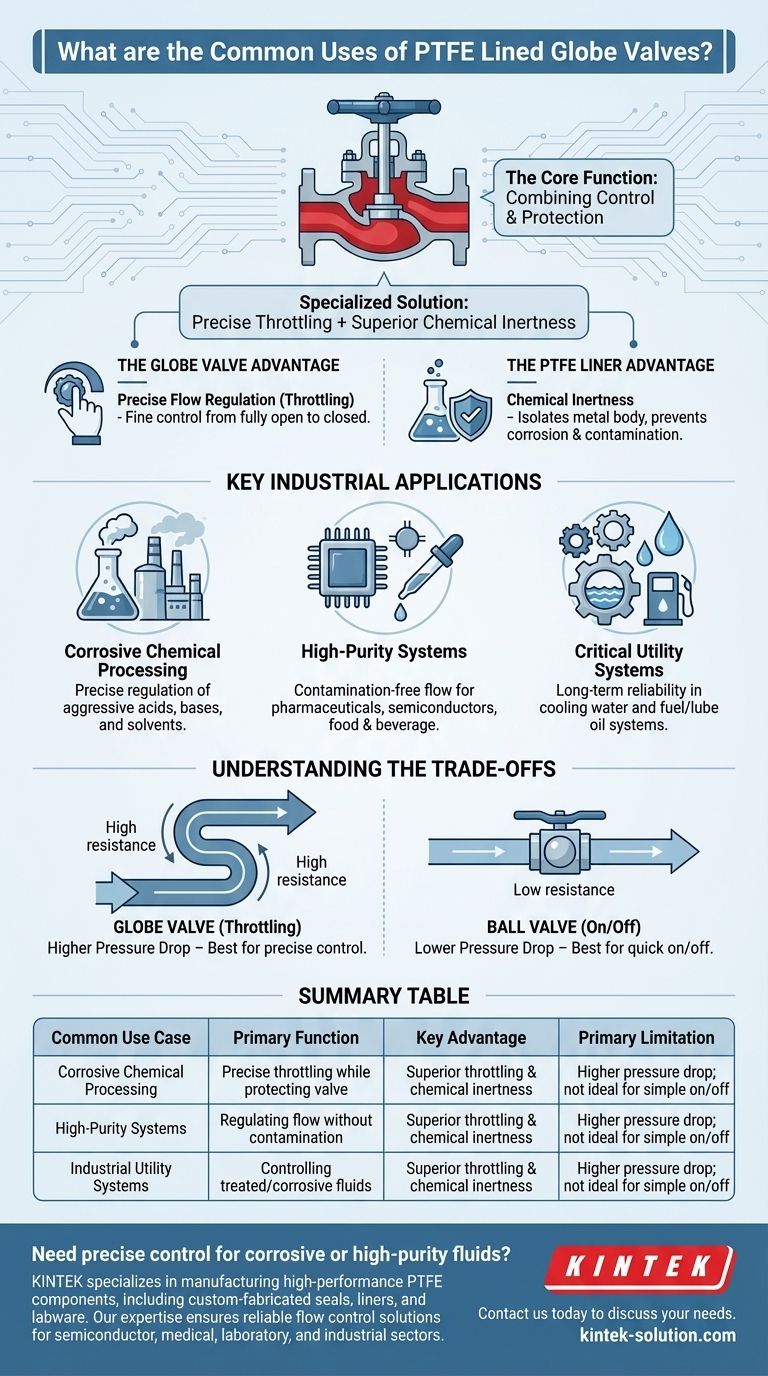

The Core Function: Combining Control and Protection

To understand the use cases, you must first understand the two key components that define the valve's function: the "globe" design and the "PTFE" liner.

The Globe Valve Advantage: Precise Flow Regulation

A globe valve is a type of linear motion valve. Unlike a ball valve that turns a quarter-turn for simple on/off service, a globe valve's disk moves perpendicularly into the flow stream.

This design is excellent for throttling, which is the careful adjustment of the flow rate. The valve's construction allows for very fine control from fully open to fully closed, a capability where many other valve types fall short.

The PTFE Liner Advantage: Chemical Inertness

The true value is added by the Polytetrafluoroethylene (PTFE) liner. This liner is a non-reactive polymer that completely isolates the valve's metal body from the fluid passing through it.

This isolation serves two critical purposes:

- It prevents the corrosive fluid from eating away at the valve's structural components.

- It prevents the fluid from being contaminated by the metal of the valve body.

This makes the valve suitable for handling everything from aggressive acids to fluids that must remain exceptionally pure.

Key Industrial Applications

The combination of precise control and chemical protection makes PTFE lined globe valves essential in specific, demanding environments.

Corrosive Chemical Processing

This is the primary application. In plants that handle aggressive media like acids, bases, or solvents, the PTFE liner is non-negotiable for protecting equipment. The globe valve design is chosen when the flow of these chemicals must be carefully regulated, not just turned on or off.

High-Purity Systems

Industries like pharmaceuticals, food and beverage, and semiconductors require that their process fluids remain completely free of contamination. A PTFE lined valve ensures that no metallic ions or other impurities leach from the valve into the product, preserving its integrity.

Critical Utility and Support Systems

This category includes the common examples cited for these valves.

- Cooling Water Systems: Water is often treated with chemicals to prevent biological growth or scale, making it corrosive over time. A PTFE liner ensures the long-term reliability of control valves in these loops.

- Fuel & Lube Oil Systems: Fuels and industrial lubricants can contain additives that are aggressive to certain metals. The globe valve's ability to precisely manage flow is critical for machinery like turbines, while the PTFE liner provides the necessary material resistance.

Understanding the Trade-offs

Choosing a PTFE lined globe valve involves acknowledging its specific strengths and weaknesses compared to other options, like a PTFE lined ball valve.

Pressure Drop: The Primary Limitation

The S-shaped internal path that fluid must take through a globe valve creates significant flow resistance. This results in a much higher pressure drop across the valve compared to a straight-through valve like a ball valve.

For systems that require high flow efficiency and minimal pressure loss, a globe valve is a poor choice.

Flow Control vs. On/Off Service

A globe valve excels at throttling and regulation. A ball valve excels at quick, low-restriction on/off service.

If your only need is to open or close a line, a PTFE lined ball valve is often a more efficient and cost-effective solution. If you need to set the flow rate to 30% or 60%, the globe valve is the superior tool.

Making the Right Choice for Your System

Your selection should be based on the primary requirement of the specific application.

- If your primary focus is precise flow regulation (throttling) of a corrosive or high-purity fluid: The PTFE lined globe valve is the definitive choice.

- If your primary focus is simple on/off control with minimal flow restriction: A PTFE lined ball valve is the better and more efficient option.

- If your fluid is non-corrosive and purity is not a major concern: A standard, unlined globe valve may provide the necessary flow control more cost-effectively.

Ultimately, selecting a PTFE lined globe valve is a strategic engineering decision for when precise process control cannot be compromised by a corrosive or sensitive fluid.

Summary Table:

| Common Use Case | Primary Function of PTFE Lined Globe Valve |

|---|---|

| Corrosive Chemical Processing | Precise throttling while protecting valve from acids/bases. |

| High-Purity Systems (Pharma, Semiconductor) | Regulating flow without contaminating sensitive media. |

| Industrial Utility Systems (Cooling Water, Fuel/Lube Oil) | Controlling treated/corrosive water and additive-laden fluids. |

| Key Advantage | Superior throttling capability combined with chemical inertness. |

| Primary Limitation | Higher pressure drop compared to ball valves; not ideal for simple on/off. |

Need precise control for corrosive or high-purity fluids?

KINTEK specializes in manufacturing high-performance PTFE components, including custom-fabricated seals, liners, and labware. Our expertise in precision production ensures reliable flow control solutions for the semiconductor, medical, laboratory, and industrial sectors—from prototypes to high-volume orders.

Contact us today to discuss how our PTFE solutions can enhance your system's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What factors influence the selection of PTFE compounds for piston rings? Match Your Application's Demands

- What is the temperature range for PTFE expansion bellows? From -200°C to 260°C for Extreme Applications

- What are the advantages of PTFE seals? Superior Performance in Extreme Chemical and Thermal Environments

- How are glass-filled PTFE rods applied in the oil and gas industry? Enhance Sealing in Extreme Conditions

- In what ways are extruded PTFE rods utilized in aerospace and automotive industries? Enhancing Performance in Extreme Conditions

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime

- What types of flange connections benefit from PTFE envelope gaskets? Seal Fragile Flanges & Harsh Chemicals

- What is one notable disadvantage of PTFE ring gaskets? The Critical Trade-Off for Chemical Resistance