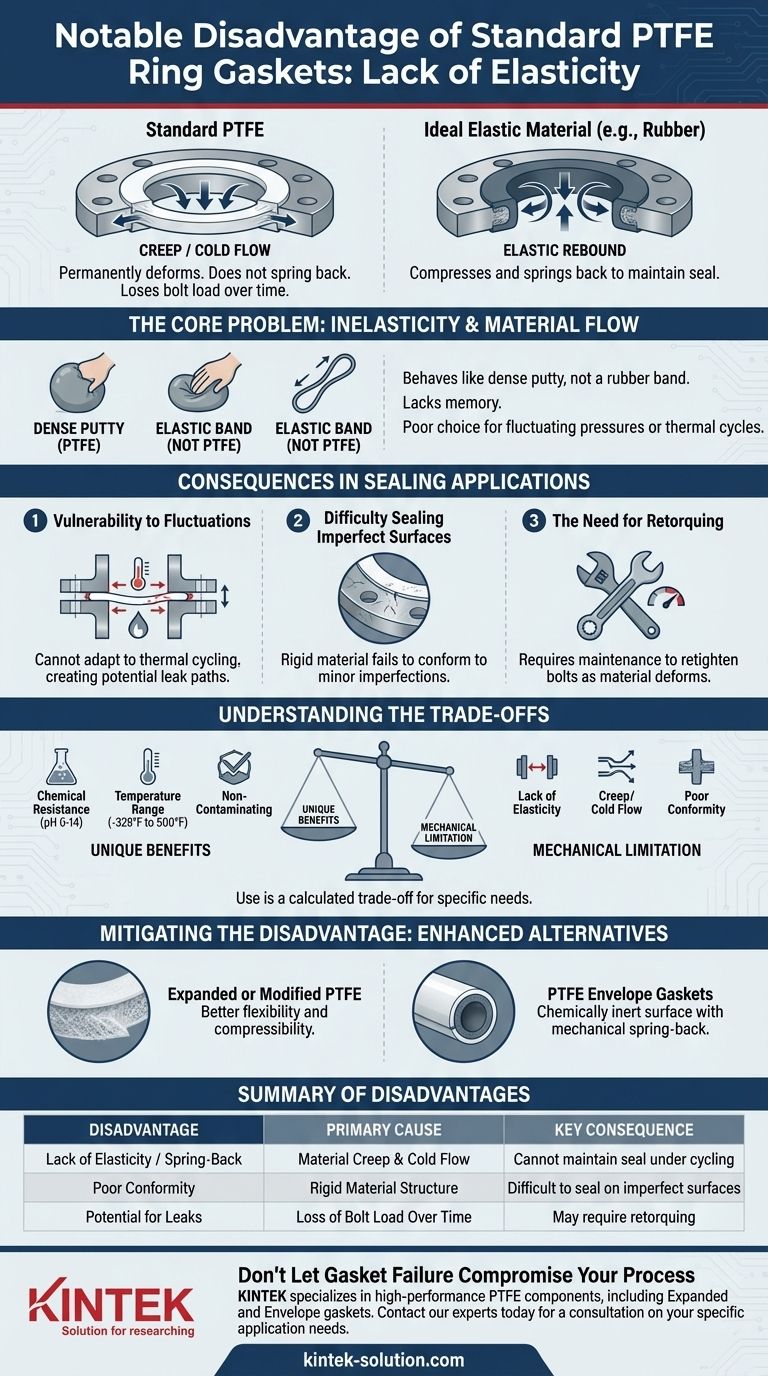

The most notable disadvantage of a standard PTFE ring gasket is its lack of elasticity. This means that once it is compressed during installation, it permanently deforms and cannot spring back to its original shape, a characteristic that leads to significant sealing challenges under specific conditions.

While prized for its unparalleled chemical and thermal resistance, pure PTFE's inability to rebound after compression (a phenomenon known as creep or cold flow) makes it a poor choice for applications with fluctuating pressures, thermal cycles, or imperfect sealing surfaces.

The Core Problem: Inelasticity and Material Flow

The fundamental weakness of standard Polytetrafluoroethylene (PTFE) is not a lack of strength, but a lack of memory. It behaves more like a dense putty than a rubber band, which has direct consequences for its performance as a gasket.

What is "Creep"?

Creep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stress. For a PTFE gasket, this means the material will gradually "flow" out from between the flanges over time, even if the bolt load remains constant.

What is "Cold Flow"?

Cold flow is a similar concept but specifically refers to PTFE's tendency to deform under load, even at ambient or elevated temperatures well below its melting point. This gradual deformation can reduce the sealing stress on the gasket, potentially leading to a leak.

The Consequence: Limited Compressibility

Because standard PTFE is rigid and inelastic, it has poor compressibility. It cannot easily conform to minor imperfections, scratches, or irregularities on a flange face, making it difficult to achieve a reliable seal on anything but perfectly machined surfaces.

Why This Matters in a Sealing Application

This lack of material "spring-back" creates several practical problems in industrial and mechanical systems.

Vulnerability to Fluctuations

Systems that experience frequent changes in pressure or temperature (thermal cycling) cause the flange bolts to expand and contract. An elastic gasket would expand and contract with the flange, maintaining a seal. A PTFE gasket cannot, creating a potential leak path during these cycles.

Difficulty Sealing Imperfect Surfaces

In real-world applications, flange surfaces are rarely perfect. They may have minor pitting, scratches, or warping. The rigidity of pure PTFE prevents it from effectively filling these small voids, compromising the integrity of the seal from the start.

The Need for Retorquing

Due to creep and cold flow, the initial bolt torque applied during installation will decrease as the gasket material deforms. This often requires maintenance teams to retighten the flange bolts after a period of time to maintain adequate sealing pressure.

Understanding the Trade-offs: Why Use PTFE at All?

Despite this significant mechanical limitation, PTFE remains a critical sealing material. Its use is a calculated trade-off, chosen when its unique benefits are non-negotiable.

Unmatched Chemical Inertness

PTFE is resistant to nearly all chemicals across the entire 0-14 pH range. It is one of the only materials that can handle the most aggressive and corrosive fluids without degrading.

Exceptional Temperature Range

Standard PTFE is stable and effective in temperatures ranging from -328°F to 500°F (-200°C to 260°C). This makes it suitable for both cryogenic and high-temperature processes.

Non-Contaminating Surface

The material is inherently non-stick, non-adhesive, and pure. This prevents it from contaminating the process media, making it essential for applications in the food, beverage, and pharmaceutical industries.

Mitigating the Disadvantage: Modified and Hybrid PTFE

To overcome the mechanical shortfalls of pure PTFE, manufacturers have developed enhanced alternatives.

Expanded or Modified PTFE

These versions alter the structure of the PTFE to introduce better flexibility and compressibility. They have a softer, more forgiving structure that seals more effectively on imperfect surfaces and resists creep far better than standard PTFE.

PTFE Envelope Gaskets

This is a hybrid solution that combines the best of both worlds. An "envelope" of thin PTFE provides the chemically inert contact surface, while a core made of a resilient material like rubber or compressed non-asbestos fiber provides the mechanical spring-back and compressibility that pure PTFE lacks.

Making the Right Choice for Your Application

Selecting the correct gasket requires balancing the chemical demands of your system against its mechanical conditions.

- If your primary focus is extreme chemical resistance in a stable, low-vibration environment with perfect flanges: A standard PTFE gasket can be a cost-effective and reliable choice.

- If your application involves thermal cycling, pressure fluctuations, or vibration: You must consider an expanded PTFE or a PTFE envelope gasket to ensure a resilient, long-lasting seal.

- If you are sealing older, slightly damaged, or non-uniform flange surfaces: The superior compressibility of a hybrid or expanded PTFE gasket is essential to prevent leaks.

Understanding this fundamental trade-off between chemical resistance and mechanical resilience is the key to selecting the correct gasket for reliable, long-term performance.

Summary Table:

| Disadvantage | Primary Cause | Key Consequence |

|---|---|---|

| Lack of Elasticity / Spring-Back | Material Creep & Cold Flow | Cannot maintain seal under thermal cycling or pressure fluctuations |

| Poor Conformity | Rigid Material Structure | Difficult to seal on imperfect or scratched flange surfaces |

| Potential for Leaks | Loss of Bolt Load Over Time | May require retorquing of flanges after initial installation |

Don't Let Gasket Failure Compromise Your Process

Understanding the limitations of standard PTFE is the first step to selecting a seal that ensures reliability and safety. The right material choice depends on a precise balance of chemical resistance and mechanical demands.

KINTEK specializes in engineering high-performance PTFE components that overcome these challenges. We don't just supply parts; we provide sealing solutions.

- Expert Material Selection: We help you choose between standard PTFE, expanded PTFE for better resilience, or hybrid envelope gaskets that combine chemical inertness with mechanical spring-back.

- Precision Manufacturing: Our components are manufactured to the highest tolerances, ensuring a perfect fit and reliable performance in critical applications.

- Custom Fabrication: From prototypes to high-volume orders, we create custom PTFE seals, liners, and labware tailored to your exact specifications for the semiconductor, medical, laboratory, and industrial sectors.

Ensure long-term sealing integrity. Contact our experts today for a consultation on your specific application needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What temperature range can Teflon (PTFE) balls withstand? -200°C to +260°C Performance Guide

- What are the key steps for properly installing PTFE seals? Ensure a Leak-Free, Long-Lasting Seal

- What materials are used to manufacture PTFE wear strips and bands? Choose the Right Filler for Your Application

- How can the susceptibility to creep and cold flow in PTFE washers be addressed? Improve Stability with Filled PTFE or Metal Backing

- What are the primary properties of PTFE rod? Unlock Extreme Performance for Demanding Applications

- What are the advantages of using PTFE encapsulated O-rings? A Cost-Effective Seal for Harsh Environments

- What are the primary uses of Expanded PTFE? Unlock Its Unique Properties for Your Application

- How are PTFE coatings applied to O-rings? Enhance Sealing Performance with Low-Friction