In short, the primary advantages of PTFE seals are their exceptional resistance to aggressive chemicals, their ability to function across an extremely wide temperature range, and their inherently low friction. These core properties make them highly durable and reliable in demanding applications where conventional elastomer seals would quickly degrade and fail.

The decision to use a PTFE seal is fundamentally a decision to solve an extreme engineering challenge. While other materials handle standard conditions, PTFE is specified when an application involves aggressive chemicals, high temperatures, high pressures, or a need for low-friction performance that would destroy lesser materials.

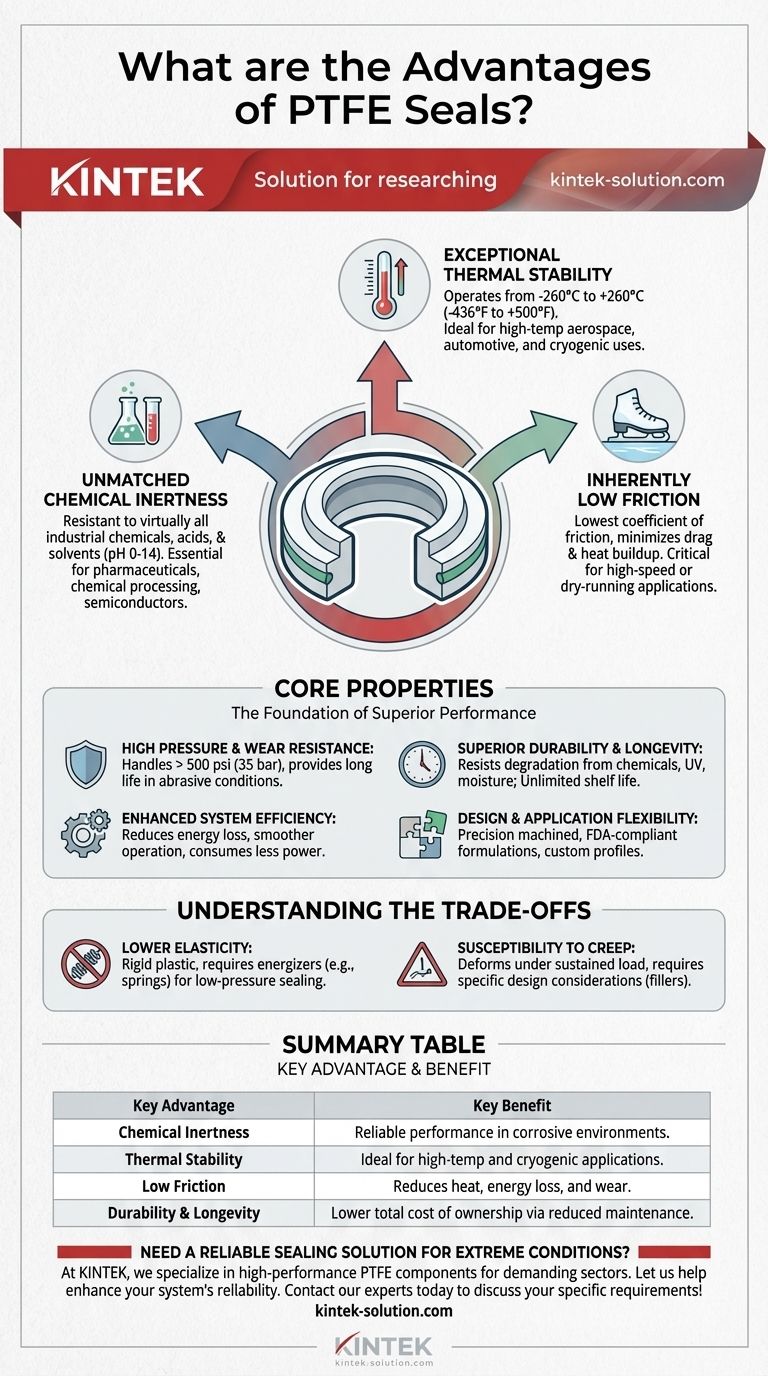

The Core Properties of PTFE Seals

To understand the advantages of Polytetrafluoroethylene (PTFE) seals, we must first look at the material's fundamental characteristics. These properties are the foundation for its superior performance in harsh environments.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. This makes it an essential material in industries like pharmaceuticals, chemical processing, and semiconductor manufacturing.

It can reliably handle fluids with a pH range from 0 to 14, ensuring seal integrity in the most corrosive environments.

Exceptional Thermal Stability

PTFE seals maintain their properties across a vast temperature range, typically from -260°C to +260°C (-436°F to +500°F).

This thermal resilience makes them the ideal choice for high-temperature applications in aerospace, automotive, and oil and gas industries, as well as for cryogenic uses where other materials become brittle.

Inherently Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" is a natural property and does not require external lubricants.

This characteristic is critical for high-speed or reciprocating applications, as it reduces heat buildup, minimizes energy loss, and prevents wear on both the seal and mating hardware.

High Pressure and Wear Resistance

While basic PTFE can be soft, specialized blends and designs allow these seals to handle extremely high pressures, often in excess of 500 psi (35 bar).

When properly configured, often with energizing springs, they resist degradation and maintain a tight seal, providing a long service life even in dry or abrasive conditions.

Translating Properties into Operational Advantages

These fundamental properties deliver tangible benefits that improve system performance, reduce costs, and increase reliability.

Superior Durability and Longevity

The combination of chemical, thermal, and environmental resistance (including UV and moisture) gives PTFE seals an exceptional lifespan.

Furthermore, PTFE does not degrade over time, giving it a virtually unlimited shelf life, a significant logistical advantage over elastomers that can harden or crack in storage.

Reduced Maintenance and Operating Costs

The long life and high durability of PTFE seals mean fewer replacements are needed. This directly translates to reduced downtime, lower labor costs, and a lower total cost of ownership over the life of the equipment.

Enhanced System Efficiency

The low-friction nature of PTFE seals improves the overall efficiency of mechanical systems. By minimizing drag and energy loss, they allow equipment to run more smoothly and consume less power.

Design and Application Flexibility

PTFE is a highly versatile material that can be precision machined into custom profiles for specific applications. This allows for optimized seal designs that are not possible with molded elastomers.

Many PTFE formulations are also FDA-compliant, making them suitable for use in food, beverage, and medical applications.

Understanding the Trade-offs

While powerful, PTFE seals are not a universal solution. Understanding their limitations is key to using them effectively.

Lower Elasticity Compared to Elastomers

PTFE is a rigid plastic, not a flexible rubber. It lacks the natural "bounciness" of an elastomer, a property known as elastic memory.

Because it doesn't readily spring back into shape after being compressed, it often requires an energizer, such as a metal spring, to provide the constant force needed for a reliable, low-pressure seal.

Susceptibility to Creep

Under a sustained load, PTFE can be subject to "creep" or "cold flow," where the material slowly deforms over time. Seal design and the use of fillers (like glass, carbon, or bronze) are critical engineering considerations to mitigate this effect.

Making the Right Choice for Your Application

Selecting the correct seal material depends entirely on the operational demands of your system.

- If your primary focus is aggressive chemical environments: PTFE is the default choice due to its near-universal chemical inertness where elastomers would dissolve or swell.

- If your primary focus is extreme temperatures (high or cryogenic): PTFE's unmatched thermal stability makes it the only reliable option when temperatures fall outside the range of rubber seals.

- If your primary focus is high-speed or dry-running applications: PTFE's naturally low friction prevents heat buildup and wear, extending the life of the entire system without lubrication.

- If your primary focus is a cost-sensitive, standard application: A common elastomer O-ring is often a more economical solution, provided no extreme chemical, thermal, or pressure conditions exist.

Ultimately, choosing a PTFE seal is an investment in reliability for conditions that demand nothing less.

Summary Table:

| Key Advantage | Description | Key Benefit |

|---|---|---|

| Chemical Inertness | Resistant to virtually all industrial chemicals, acids, and solvents (pH 0-14). | Reliable performance in corrosive environments (e.g., chemical processing, pharmaceuticals). |

| Thermal Stability | Operates from -260°C to +260°C (-436°F to +500°F). | Ideal for high-temperature and cryogenic applications where elastomers fail. |

| Low Friction | Naturally low coefficient of friction, often compared to wet ice on wet ice. | Reduces heat buildup, energy loss, and wear in high-speed or dry-running systems. |

| Durability & Longevity | Resists degradation from chemicals, UV, and moisture; unlimited shelf life. | Lower total cost of ownership via reduced maintenance, downtime, and replacements. |

Need a reliable sealing solution for extreme conditions?

At KINTEK, we specialize in manufacturing high-performance, precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication ensures you get a perfect-fit solution, from prototypes to high-volume orders, designed to withstand your most demanding chemical, thermal, and pressure challenges.

Let us help you enhance your system's reliability and efficiency. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are the primary characteristics of PTFE seals? Unmatched Performance for Extreme Conditions

- What are the five outstanding characteristics of PTFE seals? Engineered for Extreme Performance

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions