In the oil and gas industry, glass-filled PTFE rods are overwhelmingly used as the raw material for machining high-performance seals, gaskets, and bearings. These components are critical for equipment operating in extreme conditions, where they must resist corrosive fluids, high pressures, and wide temperature ranges. The glass filler fundamentally enhances the mechanical properties of standard PTFE, making it suitable for these demanding roles.

The core reason for using glass-filled PTFE is to combine the exceptional chemical and thermal resistance of PTFE with the increased strength, rigidity, and wear resistance provided by glass fibers. This creates a superior sealing material that prevents leaks and ensures operational integrity in harsh downhole, subsea, and processing environments.

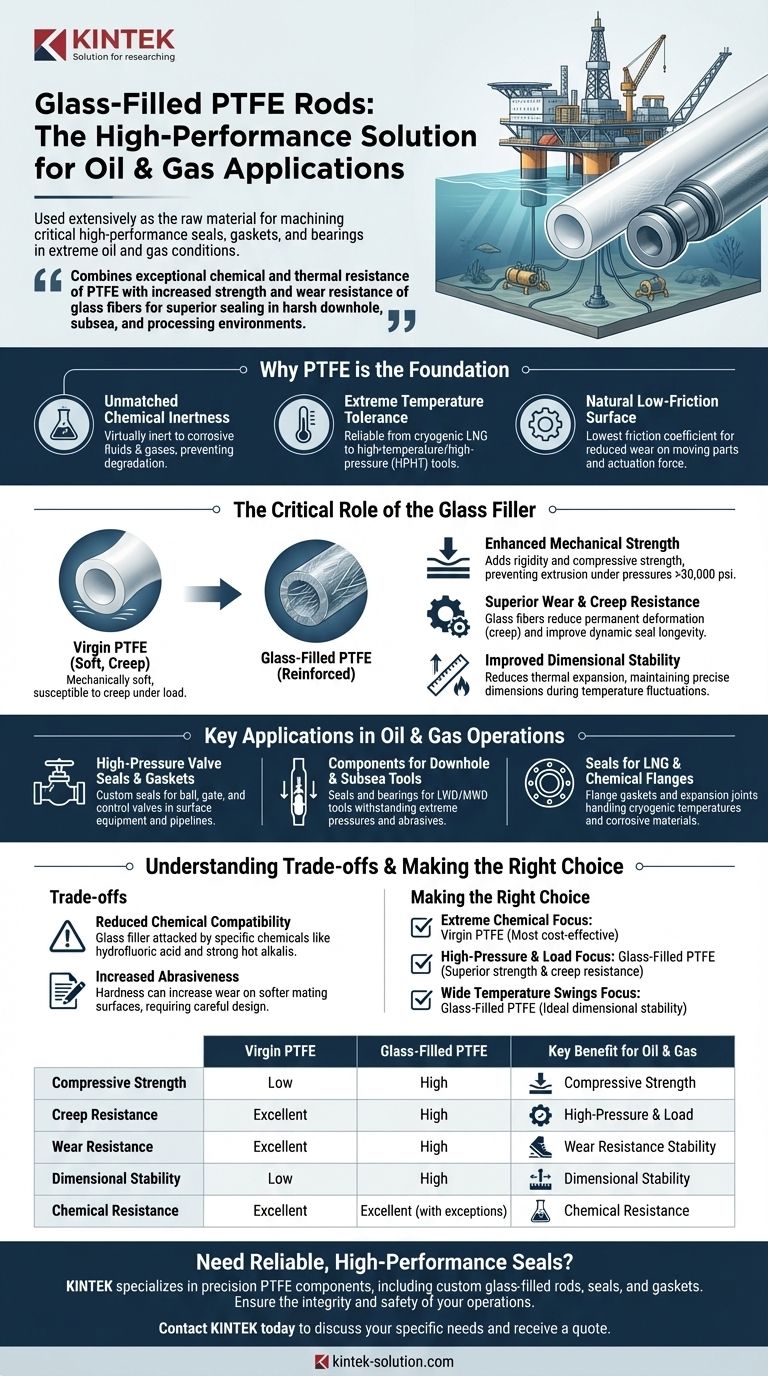

Why PTFE is the Foundation Material

Before understanding the role of the glass filler, it's essential to recognize the inherent properties of Polytetrafluoroethylene (PTFE) that make it a baseline choice for demanding industries.

Unmatched Chemical Inertness

PTFE is virtually inert to most chemicals, including the aggressive corrosive fluids and gases commonly encountered in oil and gas extraction and processing. This prevents material degradation and ensures a long service life.

Extreme Temperature Tolerance

The material maintains its properties across a vast temperature spectrum. This makes it reliable in everything from cryogenic applications like LNG equipment to high-temperature, high-pressure (HPHT) downhole tools.

Natural Low-Friction Surface

PTFE has one of the lowest coefficients of friction of any solid material. This is highly beneficial in components like valve seals, where it reduces actuation force and minimizes wear on moving parts.

The Critical Role of the Glass Filler

While virgin PTFE has excellent properties, it is mechanically soft and can deform under load. Adding glass fibers directly addresses these limitations.

Enhanced Mechanical Strength

The primary function of the glass filler is to add rigidity and compressive strength. This prevents the seal or gasket from being extruded or deformed under the immense pressures found in oil and gas systems, which can exceed 30,000 psi (2070 bar).

Superior Wear and Creep Resistance

Virgin PTFE is susceptible to "creep"—a slow, permanent deformation under sustained pressure. Glass fibers act as a reinforcing matrix, significantly reducing creep and improving wear resistance, which is vital for the longevity of dynamic seals and bushings.

Improved Dimensional Stability

The glass filler reduces the rate of thermal expansion. This ensures that a seal maintains its precise dimensions and sealing force even with significant temperature fluctuations, preventing leaks during operational cycles.

Key Applications in Oil & Gas Operations

The enhanced properties of glass-filled PTFE make it the go-to material for a range of critical components across the industry.

High-Pressure Valve Seals and Gaskets

This is the most common application. Rods are machined into custom seals for ball valves, gate valves, and control valves used in surface drilling equipment, pipelines, and processing plants.

Components for Downhole and Subsea Tools

In equipment like Logging While Drilling (LWD) and Measurement While Drilling (MWD) tools, reliability is paramount. Glass-filled PTFE is used for seals and bearings that must withstand extreme downhole pressures and abrasive conditions.

Seals for LNG and Chemical Flanges

In Liquefied Natural Gas (LNG) facilities and chemical pipelines, glass-filled PTFE is used for flange gaskets and expansion joints. It provides a reliable seal that can handle cryogenic temperatures, high pressures, and corrosive materials simultaneously.

Understanding the Trade-offs

No material is perfect. While glass-filled PTFE is a phenomenal problem-solver, it's important to be aware of its specific limitations.

Reduced Chemical Compatibility

While PTFE itself is nearly inert, the glass filler can be attacked by a few specific chemicals, such as hydrofluoric acid and strong hot alkalis. In these rare cases, a different filler or virgin PTFE may be required.

Increased Abrasiveness

The hardness of the glass fibers can increase wear on softer mating surfaces, such as stainless steel valve stems or shafts. This must be considered during the component design phase to ensure the longevity of the entire assembly.

Making the Right Choice for Your Application

Selecting the correct material requires matching its properties to the primary operational challenge.

- If your primary focus is sealing against extremely aggressive chemicals with minimal mechanical stress: Virgin PTFE may be a sufficient and more cost-effective choice.

- If your primary focus is high-pressure sealing with significant mechanical loads and wear conditions: Glass-filled PTFE is the definitive choice for its superior strength and creep resistance.

- If your primary focus is maintaining seal integrity across wide temperature swings: The dimensional stability offered by glass-filled PTFE makes it ideal for critical flanges and expansion joints.

Ultimately, understanding the role of glass filler empowers engineers to transform PTFE from a simple non-stick polymer into a high-performance engineering material capable of ensuring safety and reliability in the world's most demanding environments.

Summary Table:

| Property | Virgin PTFE | Glass-Filled PTFE | Key Benefit for Oil & Gas |

|---|---|---|---|

| Compressive Strength | Low | High | Resists extrusion under high pressure (>30,000 psi) |

| Creep Resistance | Low | High | Maintains seal integrity under sustained load |

| Wear Resistance | Low | High | Longer life for dynamic seals and bushings |

| Dimensional Stability | Moderate | High | Consistent performance across temperature swings |

| Chemical Resistance | Excellent | Excellent (with few exceptions*) | Handles corrosive fluids and gases |

| *Note: Glass filler can be attacked by hydrofluoric acid and strong hot alkalis. |

Need reliable, high-performance seals for your oil and gas equipment?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom-machined glass-filled PTFE rods, seals, gaskets, and liners. Our expertise ensures your components meet the extreme demands of downhole, subsea, and processing environments.

We provide:

- Enhanced Material Performance: Our glass-filled PTFE components offer the superior strength and creep resistance critical for high-pressure applications.

- Custom Fabrication: From prototypes to high-volume orders, we tailor solutions to your exact specifications.

- Industry Expertise: We serve the semiconductor, medical, laboratory, and specialized industrial sectors, including oil and gas.

Ensure the integrity and safety of your operations. Contact KINTEK today to discuss your specific application needs and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications