PTFE envelope gaskets are the preferred solution for flange connections that require the superior chemical resistance of PTFE but also need the mechanical flexibility and compressibility of a different core material. These gaskets excel in applications involving fragile or uneven flanges, aggressive chemicals, and processes where product purity is paramount, such as in the food and pharmaceutical industries.

The core value of a PTFE envelope gasket is its hybrid design. It combines the near-universal chemical inertness and non-stick properties of a PTFE shell with the mechanical resilience of an inner core, creating a seal that is both highly resistant and highly conformable.

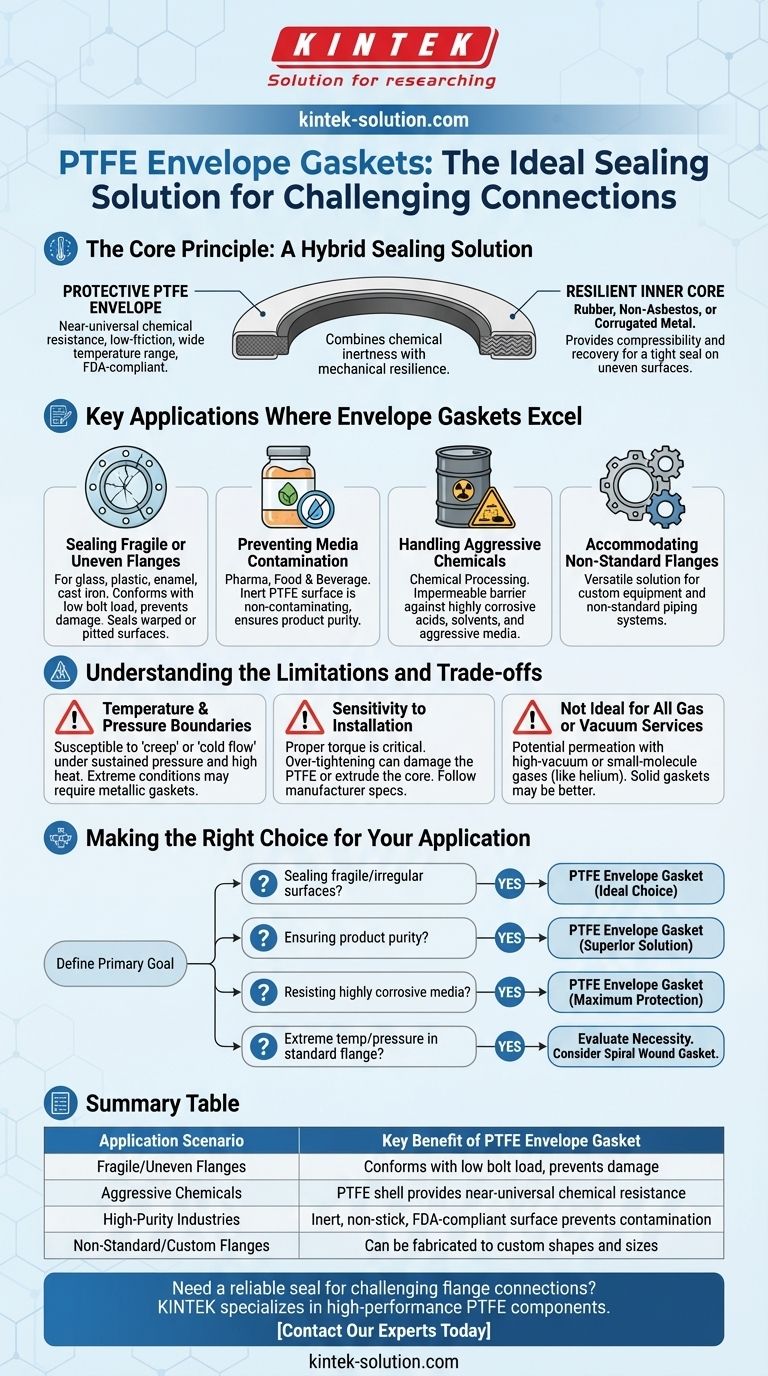

The Core Principle: A Hybrid Sealing Solution

A PTFE envelope gasket is not a single material but a composite component. Understanding this two-part construction is key to knowing when to use it.

The Protective PTFE "Envelope"

The outer layer, or "envelope," is made from Polytetrafluoroethylene (PTFE). This material provides the primary sealing benefits.

PTFE is specified for its near-universal chemical resistance, low-friction surface, and wide operating temperature range. This makes it ideal for handling aggressive media without degrading.

It is also a non-contaminating material recognized as food-grade, making it essential for FDA applications in pharmaceutical and food processing.

The Resilient Inner Core

Inside the PTFE shell is a core material, often made of rubber, non-asbestos fibers, or even corrugated metal. This core is what gives the gasket its mechanical properties.

The inner core provides the compressibility and recovery needed to create a tight seal, especially on flanges that are not perfectly flat. It allows the gasket to conform to surface irregularities under bolt load.

The choice of core material depends on the application's required temperature, pressure, and degree of flexibility.

Key Applications Where Envelope Gaskets Excel

This hybrid design makes PTFE envelope gaskets a problem-solver in several specific scenarios.

Sealing Fragile or Uneven Flanges

Many flanges are made from materials like glass, plastic, enamel, or cast iron that can crack or deform under the high bolt loads required for solid gaskets.

The soft, conformable nature of a PTFE envelope gasket allows it to create a reliable seal with less compressive force, protecting the integrity of these fragile flanges.

This same conformability makes it highly effective for sealing warped, pitted, or otherwise uneven flange surfaces where a rigid gasket would fail.

Preventing Media Contamination

In the pharmaceutical, bioprocessing, and food and beverage industries, preventing contamination is a critical operational requirement.

The inert PTFE surface does not react with, adhere to, or leach into the process media. This ensures product purity and reduces the risk of batch spoilage.

Handling Aggressive Chemicals

The chemical processing industry relies on these gaskets to safely handle highly corrosive acids, solvents, and other aggressive substances.

The PTFE envelope acts as an impermeable barrier, protecting the flange and the inner core material from chemical attack, ensuring operational safety and extending the service life of the connection.

Accommodating Non-Standard Flanges

PTFE envelope gaskets can be fabricated in a wide variety of standard and non-standard shapes and sizes. This makes them a versatile solution for custom equipment or non-standard piping systems where off-the-shelf gaskets are not available.

Understanding the Limitations and Trade-offs

While highly effective, PTFE envelope gaskets are not a universal solution. Understanding their limitations is crucial for proper application.

Temperature and Pressure Boundaries

PTFE is susceptible to "creep" or "cold flow," a tendency to slowly deform under sustained pressure, especially at elevated temperatures.

While excellent for many high-temperature and high-pressure duties, they may not be suitable for extreme conditions where a metallic gasket (like a spiral wound gasket) would provide greater resistance to blowout and creep.

Sensitivity to Installation

Proper installation is critical. Over-tightening the flange bolts can damage the thin PTFE envelope or cause the softer inner core to extrude, leading to seal failure.

Always follow the manufacturer's torque specifications to achieve the optimal balance of compression and material integrity.

Not Ideal for All Gas or Vacuum Services

For high-vacuum applications or services involving small-molecule gases (like helium), the potential for permeation through the PTFE layer and the core material can be a concern.

In these critical cases, a solid metal or other specialized gasket may provide a more reliable, leak-free seal.

Making the Right Choice for Your Application

To select the correct gasket, you must first define your primary engineering goal.

- If your primary focus is sealing fragile (glass-lined, plastic) or irregular flange surfaces: A PTFE envelope gasket with a soft, conformable core is the ideal choice.

- If your primary focus is ensuring product purity in food, pharmaceutical, or bioprocessing: The inert, FDA-compliant surface of a PTFE envelope gasket is the superior solution to prevent contamination.

- If your primary focus is resisting highly corrosive media in chemical processing: The near-universal chemical inertness of the PTFE envelope provides maximum protection for the flange connection.

- If your primary focus is extreme temperature and pressure in a standard metal flange: Carefully evaluate if a PTFE envelope gasket is necessary, as a more robust spiral wound gasket may offer better performance against creep and blowout.

By understanding its composite design, you can confidently deploy the PTFE envelope gasket as a precise solution for your most demanding sealing challenges.

Summary Table:

| Application Scenario | Key Benefit of PTFE Envelope Gasket |

|---|---|

| Fragile/Uneven Flanges (glass, plastic) | Conforms with low bolt load, prevents damage |

| Aggressive Chemicals | PTFE shell provides near-universal chemical resistance |

| High-Purity Industries (Food, Pharma) | Inert, non-stick, FDA-compliant surface prevents contamination |

| Non-Standard/Custom Flanges | Can be fabricated to custom shapes and sizes |

Need a reliable seal for challenging flange connections? KINTEK specializes in manufacturing high-performance PTFE components, including custom envelope gaskets. Our precision production ensures a perfect fit and superior chemical resistance for your applications in the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, we deliver solutions that protect your equipment and ensure operational safety. Contact our experts today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the advantages of using PTFE lined ball valves in corrosive environments? Achieve Superior Corrosion Resistance

- What are the operational benefits of the PTFE seat butterfly valve? Superior Control for Corrosive & Sensitive Media

- What benefits does PTFE provide in athletic footwear? Enhancing Performance with Low-Friction & Non-Stick Solutions

- How are Teflon sheets used in hardware manufacturing? Solve Extreme Friction, Chemical, and Heat Problems

- What are the key components of a PTFE lined butterfly valve? The Engineered System for Corrosive & High-Purity Media

- What are some specific applications of Teflon coatings in the food industry? Solve Sticking, Buildup, and Efficiency Problems

- Why are PTFE rotary shaft seals essential for high-performance applications? Unlock Unmatched Reliability in Extreme Conditions

- What are the advantages of glass-filled Teflon balls? Enhanced Strength & Wear Resistance for Demanding Applications