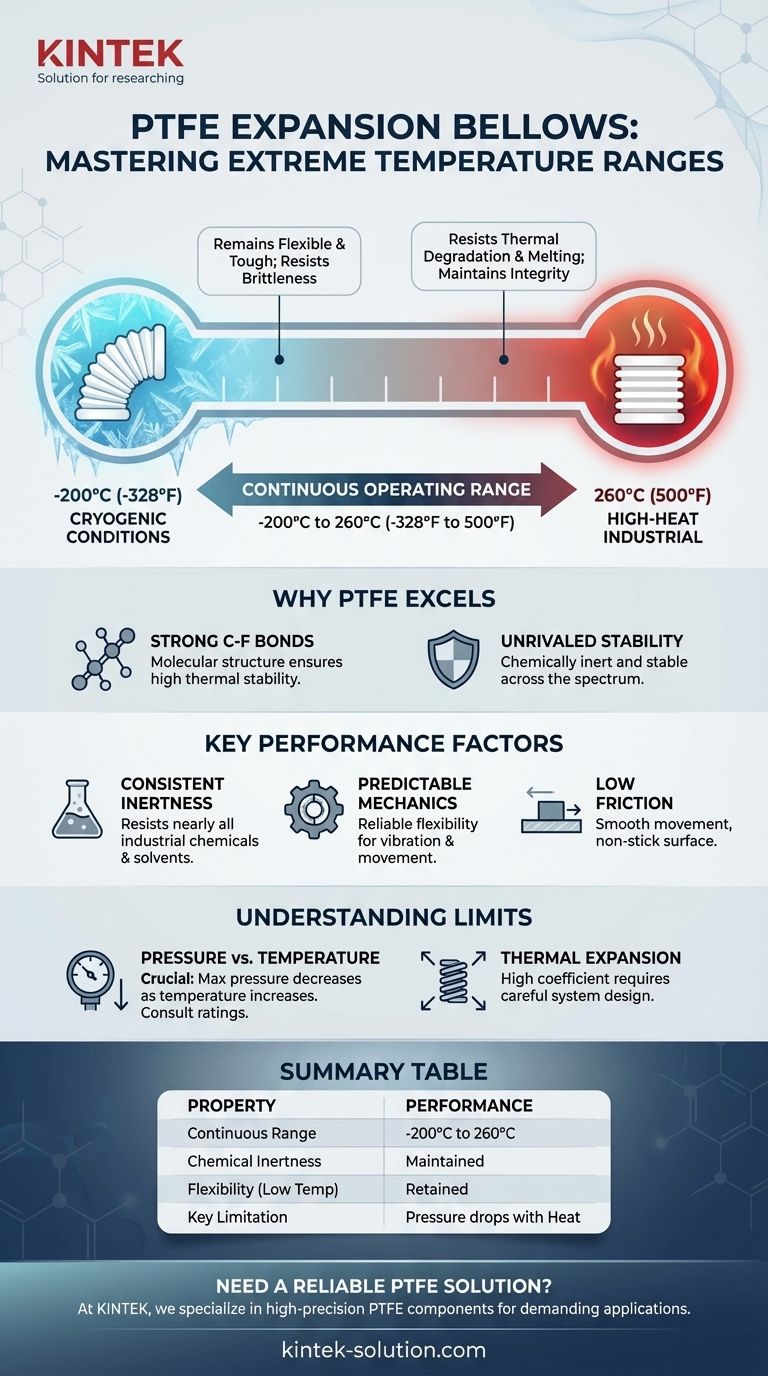

For all practical engineering purposes, the continuous operating temperature range for Polytetrafluoroethylene (PTFE) expansion bellows is from -200°C to 260°C (-328°F to 500°F). This exceptionally wide range makes PTFE a uniquely versatile material, capable of performing reliably in both extreme cryogenic conditions and high-heat industrial processes without significant degradation.

The core reason for selecting PTFE is its unrivaled thermal stability among polymers. Its unique molecular structure ensures it remains flexible and chemically inert across a vast temperature spectrum where most other materials would fail through brittleness or decomposition.

Why PTFE Excels in Extreme Temperatures

The remarkable temperature resistance of PTFE is not an accident; it is a direct result of its molecular makeup. Understanding this foundation is key to trusting its performance in critical applications.

The Strength of Carbon-Fluorine Bonds

At its core, PTFE consists of a long chain of carbon atoms completely shielded by a sheath of fluorine atoms. The bond between carbon and fluorine is one of the strongest known in organic chemistry.

This powerful bond requires a tremendous amount of thermal energy to disrupt, which directly translates to PTFE's high-temperature stability.

Maintaining Integrity at High Heat

Up to its continuous service limit of 260°C (500°F), PTFE resists thermal degradation. It will not melt or lose its fundamental structure within this range.

Its actual melting point is significantly higher, around 327°C (621°F), providing a substantial safety margin for temperature excursions.

Resisting Brittleness at Cryogenic Lows

While many materials become rigid and brittle at low temperatures, PTFE retains a remarkable degree of flexibility and toughness.

This property prevents cracking and failure in cryogenic applications, such as those involving liquefied gases, down to temperatures as low as -200°C and even approaching -260°C in some grades.

Key Performance Factors Across the Temperature Range

An expansion bellow must do more than simply survive; it must remain functional. PTFE maintains its most critical properties across its entire operating range.

Consistent Chemical Inertness

A primary reason for using PTFE is its resistance to nearly all industrial chemicals and solvents. This inertness is not compromised by temperature, ensuring reliable performance whether the medium is hot acid or cryogenic fluid.

Predictable Mechanical Properties

While all materials change with temperature, PTFE's mechanical properties remain predictable and functional. It reliably provides the flexibility and durability required to absorb vibration, thermal expansion, and system movements.

Low Friction Characteristics

PTFE's famously low coefficient of friction (non-stick quality) is also maintained across the temperature spectrum. This ensures smooth, unrestricted movement and prevents material buildup on its surface.

Understanding the Trade-offs and Limits

While highly capable, no material is without its operational limits. Acknowledging these is crucial for safe and effective system design.

Short-Term vs. Continuous Use

The 260°C (500°F) rating is for continuous, long-term operation. While some data suggests PTFE can tolerate brief excursions up to 290-300°C, this accelerates material aging and should not be considered a normal operating condition.

The Impact of Pressure

Temperature and pressure are inextricably linked. The maximum pressure a PTFE bellow can withstand decreases as the temperature increases. Always consult the manufacturer's specific pressure-temperature rating chart for the exact bellow you are using.

Thermal Expansion and Contraction

PTFE has a relatively high coefficient of thermal expansion. While the expansion bellow itself is designed to compensate for this, engineers must account for this property in the overall system design to prevent undue stress on connecting components.

Making the Right Choice for Your Application

Use these guidelines to match PTFE's capabilities to your specific engineering goal.

- If your primary focus is high-heat industrial processes: You can confidently specify PTFE for continuous use up to 260°C (500°F), knowing it maintains its chemical resistance and structural integrity.

- If your primary focus is cryogenic systems: PTFE is an excellent choice, as it retains its flexibility and will not become brittle or crack at temperatures down to -200°C (-328°F).

- If your system involves high pressure at elevated temperatures: You must verify that your operating conditions fall within the safe zone of the manufacturer’s pressure-temperature curve for that specific bellow.

Ultimately, PTFE's exceptional thermal stability provides a reliable and versatile solution for the most demanding fluid transfer applications.

Summary Table:

| Property | Performance Across Temperature Range |

|---|---|

| Continuous Operating Range | -200°C to 260°C (-328°F to 500°F) |

| Chemical Inertness | Maintained from cryogenic to high temperatures |

| Flexibility | Retained, resists brittleness at low temps |

| Key Limitation | Max pressure decreases as temperature increases |

Need a reliable PTFE expansion bellow for your extreme-temperature application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services ensure your expansion bellows are engineered to perform reliably within the critical -200°C to 260°C range, handling thermal expansion, vibration, and aggressive chemicals.

We provide solutions from prototypes to high-volume orders, prioritizing precision and durability.

Contact our experts today to discuss your specific requirements and get a custom solution quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments