In industrial settings, Teflon balls are primarily used in applications that demand extremely low friction, high chemical resistance, and material purity. Their most common uses are in components like ball valves, check valves, bearings, and as volume displacement media in sensitive environments such as medical, pharmaceutical, and food preparation equipment.

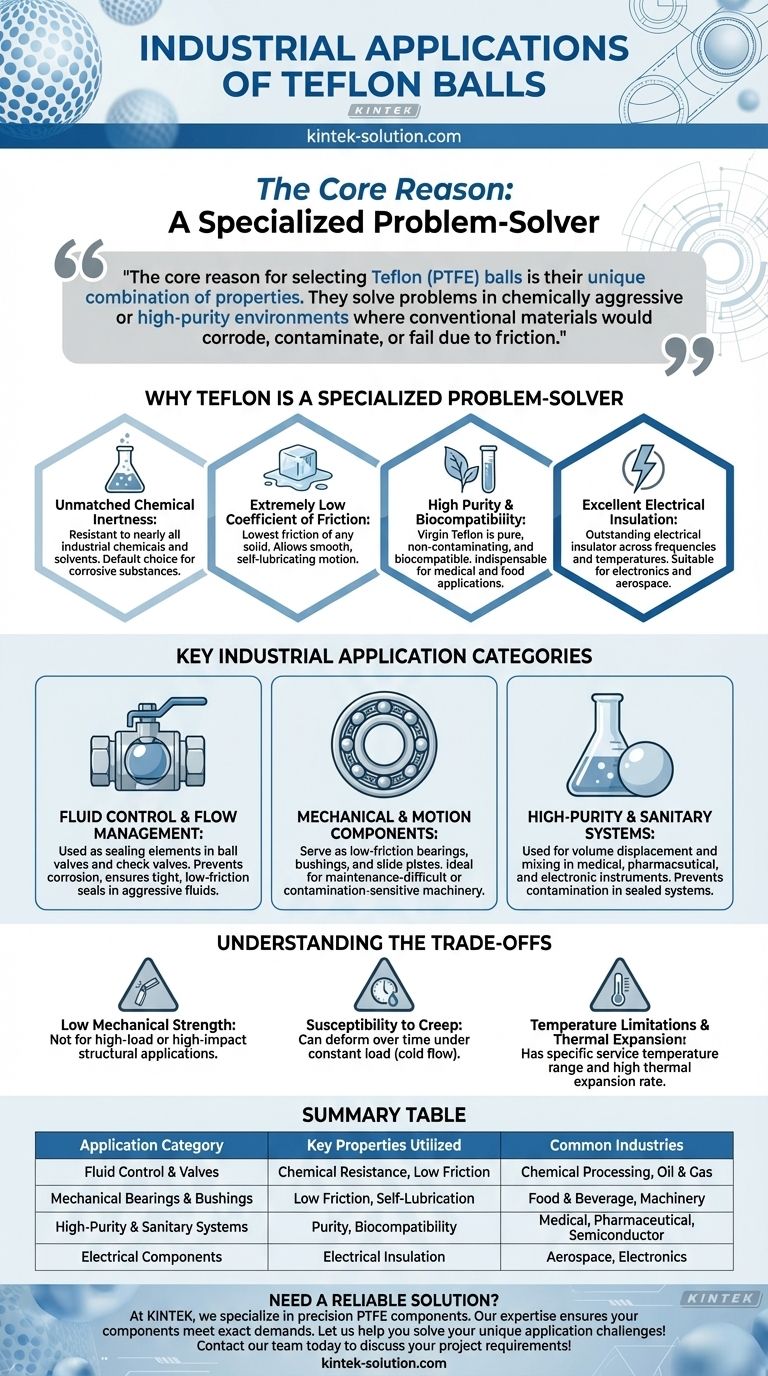

The core reason for selecting Teflon (PTFE) balls is not strength, but their unique combination of properties. They solve problems in chemically aggressive or high-purity environments where conventional materials would corrode, contaminate, or fail due to friction.

Why Teflon is a Specialized Problem-Solver

The versatility of Teflon balls stems from a distinct set of material properties. Understanding these characteristics is key to recognizing their ideal applications.

Unmatched Chemical Inertness

Teflon (PTFE) is resistant to nearly all industrial chemicals and solvents. This makes it the default choice for components that will be exposed to highly corrosive or aggressive substances.

This property is critical in the chemical, pharmaceutical, and paper industries, where equipment must handle harsh materials without degrading.

Extremely Low Coefficient of Friction

Teflon has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This allows parts to move smoothly without the need for external lubricants.

This self-lubricating nature is ideal for bearings, slide plates, and gears in machinery where maintenance is difficult or contamination from lubricants is unacceptable.

High Purity and Biocompatibility

Virgin Teflon is exceptionally pure and does not contaminate the substances it contacts. It is also biocompatible, meaning it is not harmful to living tissues.

These traits make it indispensable in medical devices, foodstuff processing equipment, and pharmaceutical manufacturing, where preventing contamination is a primary concern.

Excellent Electrical Insulation

Teflon is an outstanding electrical insulator, maintaining its properties across a wide range of frequencies and temperatures.

This makes it suitable for electronic components and applications in the aerospace industry, where reliable insulation is critical for performance and safety.

Key Industrial Application Categories

Based on these properties, the use of Teflon balls can be grouped into several major categories.

Fluid Control and Flow Management

Teflon balls are frequently used as the sealing element in ball valves and check valves. Their chemical resistance prevents corrosion, and their smooth surface ensures a tight, low-friction seal against the valve seat.

They are also used in compressors and other systems managing aggressive fluids.

Mechanical and Motion Components

In machinery, Teflon balls serve as low-friction bearings and bushings. They are particularly useful in environments where traditional lubricated metal bearings would fail due to chemical attack or where lubricant leakage cannot be tolerated.

They can also be found in slide plates and certain gear applications that require smooth, quiet operation.

High-Purity and Sanitary Systems

Due to their purity, Teflon balls are used for volume displacement and mixing in medical, electronic, and pharmaceutical instruments. They can fill space or agitate liquids within a sealed system without introducing contaminants.

This is common in measurement instruments and other sensitive laboratory or production equipment.

Understanding the Trade-offs

While its properties are exceptional, Teflon is not a universal solution. Its limitations are just as important to understand as its strengths.

Low Mechanical Strength

Teflon is a relatively soft material with low tensile strength and surface hardness compared to metals or even other plastics. It is not suitable for high-load or high-impact structural applications.

Susceptibility to Creep

Under a constant load, Teflon can slowly deform over time, a phenomenon known as "creep" or "cold flow." This must be accounted for in the design of seals and bearings to ensure long-term performance.

Temperature Limitations

While resistant to high temperatures, Teflon has a distinct service temperature range. It also has a high rate of thermal expansion, which can be a critical design factor when mating with metal components.

Making the Right Choice for Your Application

Selecting Teflon balls should be a deliberate decision based on the specific problem you need to solve.

- If your primary focus is chemical resistance: Teflon balls are an excellent choice for valves and bearings in systems handling aggressive chemicals.

- If your primary focus is low-friction, self-lubricating motion: They are ideal for low-load bearings or slides in cleanroom or food-grade equipment.

- If your primary focus is purity and non-contamination: Teflon is the standard for medical, pharmaceutical, and semiconductor applications requiring inert contact surfaces.

- If your primary focus is high mechanical load or impact resistance: You should consider alternative materials like stainless steel, ceramic, or high-strength engineering plastics.

Ultimately, a Teflon ball is a specialized component chosen when its unique chemical and physical properties are the only way to meet demanding operational requirements.

Summary Table:

| Application Category | Key Properties Utilized | Common Industries |

|---|---|---|

| Fluid Control & Valves | Chemical Resistance, Low Friction | Chemical Processing, Oil & Gas |

| Mechanical Bearings & Bushings | Low Friction, Self-Lubrication | Food & Beverage, Machinery |

| High-Purity & Sanitary Systems | Purity, Biocompatibility | Medical, Pharmaceutical, Semiconductor |

| Electrical Components | Electrical Insulation | Aerospace, Electronics |

Need a reliable solution for chemically aggressive or high-purity environments?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom Teflon balls, seals, liners, and labware. Our expertise ensures your components meet the exact demands of the semiconductor, medical, laboratory, and industrial sectors—from initial prototypes to high-volume production runs.

Let us help you solve your unique application challenges with materials engineered for performance. Contact our team today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What factors determine the different grades of PTFE balls available? Select the Right Grade for Your Application

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime

- In which industries are Teflon (PTFE) balls commonly used? Key Applications & Benefits

- What are the overall advantages of using PTFE balls in fluid management systems? Enhance Reliability & Efficiency

- What are the advantages of PTFE balls over metals or alloys? Superior Chemical & Friction Resistance