In short, standard PTFE gaskets are the premier choice for applications where chemical resistance, temperature stability, or purity are the most critical factors. They are best suited for industries like chemical processing, food and beverage manufacturing, pharmaceuticals, and for specialized electrical insulation.

The core takeaway is that while standard Polytetrafluoroethylene (PTFE) offers near-universal chemical inertness and a vast temperature range, its primary limitation is mechanical. Understanding this trade-off between chemical resilience and physical behavior is key to using it correctly.

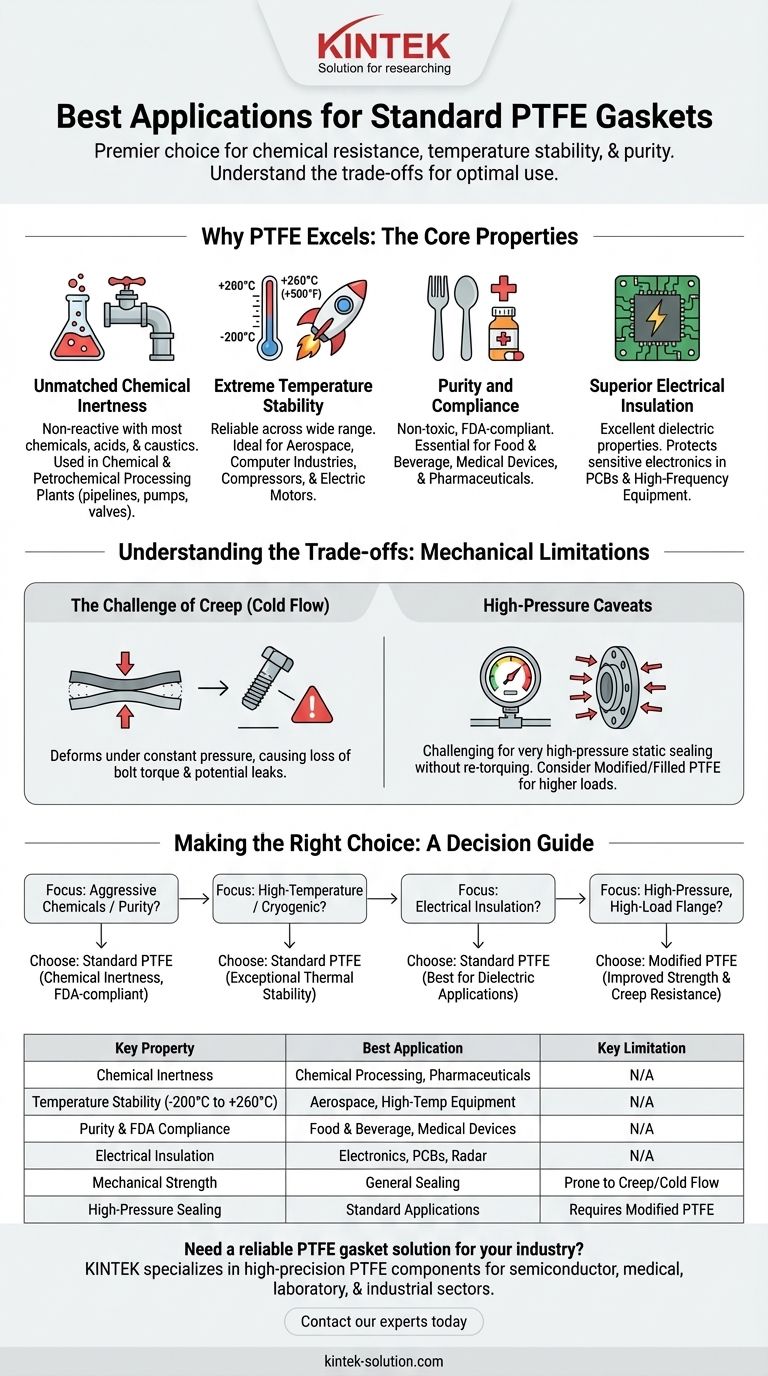

Why PTFE Excels: The Core Properties

To understand where a standard PTFE gasket works best, you must first understand its fundamental characteristics. Its applications are a direct result of a unique combination of properties not found in most other sealing materials.

Unmatched Chemical Inertness

A key feature of PTFE is that it is non-reactive with almost all industrial chemicals, acids, and caustics. This makes it an essential material in highly corrosive environments.

This property is why PTFE is the default choice for gaskets in chemical and petrochemical processing plants, where it is used in pipelines, pumps, and valves to handle aggressive fluids safely.

Extreme Temperature Stability

Standard PTFE gaskets perform reliably across an exceptionally wide temperature range, from cryogenic conditions up to approximately +260°C (+500°F).

This makes them ideal for high-heat industrial applications, including seals for compressors and electric motors, as well as specialized uses in the aerospace and computer industries where components must withstand significant temperature fluctuations.

Purity and Compliance

PTFE is inherently non-toxic, non-contaminating, and odorless. Many grades are FDA-compliant, making them safe for direct contact with consumable products.

This is the primary reason it is heavily utilized in food and beverage manufacturing, medical device components, and pharmaceutical production, where preventing contamination is a non-negotiable requirement.

Superior Electrical Insulation

Virgin PTFE is one of the best known materials for electrical and thermal insulation. It has excellent dielectric properties, meaning it does not conduct electricity.

This makes it invaluable for protecting sensitive electronics, where it is used as insulators on printed circuit boards (PCBs) and in high-frequency communication and radar equipment.

Understanding the Trade-offs of Standard PTFE

While its chemical and thermal properties are outstanding, it is critical to understand the mechanical limitations of standard (unfilled) PTFE gaskets to avoid application failure.

The Challenge of Creep (Cold Flow)

Standard PTFE is a relatively soft material that can "creep" or "cold flow." This means it will slowly deform over time when subjected to constant pressure, especially at elevated temperatures.

This deformation can cause a loss of bolt torque in a flanged connection, leading to a reduction in sealing pressure and a potential leak.

High-Pressure Application Caveats

While PTFE is compressible and creates an excellent seal, its tendency to creep makes it challenging for very high-pressure static sealing applications without proper design or periodic re-torquing. The seal may be tight initially but can loosen over time.

When to Consider Modified PTFE

To overcome the issue of creep, manufacturers add filler materials like glass, carbon, or bronze to standard PTFE. This "modified" or "filled" PTFE offers significantly improved mechanical strength and creep resistance, making it suitable for higher pressures and more demanding structural roles.

Making the Right Choice for Your Application

Use the core strengths of standard PTFE to guide your decision.

- If your primary focus is handling aggressive chemicals or ensuring product purity: Standard PTFE is an excellent first choice due to its chemical inertness and FDA-compliant grades.

- If your primary focus is sealing in high-temperature or cryogenic environments: Standard PTFE's exceptional thermal stability makes it a very strong candidate.

- If your primary focus is a high-pressure, high-load flange: You must account for potential creep with standard PTFE and should strongly consider a filled or modified grade for long-term reliability.

- If your primary focus is electrical insulation: Virgin PTFE is one of the best and most reliable materials available for dielectric applications.

By understanding both its exceptional properties and its physical limitations, you can confidently deploy standard PTFE gaskets where they will provide the most reliable service.

Summary Table:

| Key Property | Best Application | Key Limitation |

|---|---|---|

| Chemical Inertness | Chemical Processing, Pharmaceuticals | N/A |

| Temperature Stability (-200°C to +260°C) | Aerospace, High-Temp Equipment | N/A |

| Purity & FDA Compliance | Food & Beverage, Medical Devices | N/A |

| Electrical Insulation | Electronics, PCBs, Radar | N/A |

| Mechanical Strength | General Sealing | Prone to Creep/Cold Flow |

| High-Pressure Sealing | Standard Applications | Requires Modified PTFE for High Loads |

Need a reliable PTFE gasket solution for your industry?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require standard PTFE for its unmatched chemical resistance or a modified grade for enhanced mechanical performance, our team provides custom fabrication from prototypes to high-volume orders.

Let us help you select the perfect material for your application. Contact our experts today for a consultation and quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- How do PTFE lined valves provide excellent chemical resistance? The Ultimate Guide to Inert Fluid Handling

- How do PTFE impellers compare to traditional impeller materials? Maximize Efficiency in Corrosive Applications

- How can PTFE's mechanical properties be enhanced? Boost Strength & Wear Resistance with Fillers

- How does the flexibility of PTFE gaskets contribute to their versatility? Sealing Imperfect Surfaces with Ease

- How does the fiber structure of ePTFE gaskets provide mechanical compensation? Sealing Imperfect Flanges

- How does the low friction property of PTFE rotary shaft seals benefit machinery? Boost Efficiency & Reliability

- What are the key differences between FEP and PFA encapsulated O-rings? A Guide to Temperature, Flexibility & Cost

- What visual feature does the PTFE Lined Spacer have? A Guide to Its High-Performance Design