In precision engineering, ultra-thin PTFE washers, with thicknesses ranging from 0.03mm to 0.1mm, are specialized components used for fine-tuning mechanical clearances, providing electrical insulation in compact designs, and creating effective seals in low-pressure systems. Their value comes from combining the unique properties of PTFE with a form factor that can solve problems at a microscopic scale.

The core function of an ultra-thin PTFE washer is not to bear heavy loads, but to solve problems of space, insulation, and sealing in highly constrained environments. Its thinness is its primary feature, enabling micro-adjustments and electrical isolation where standard components are simply too large.

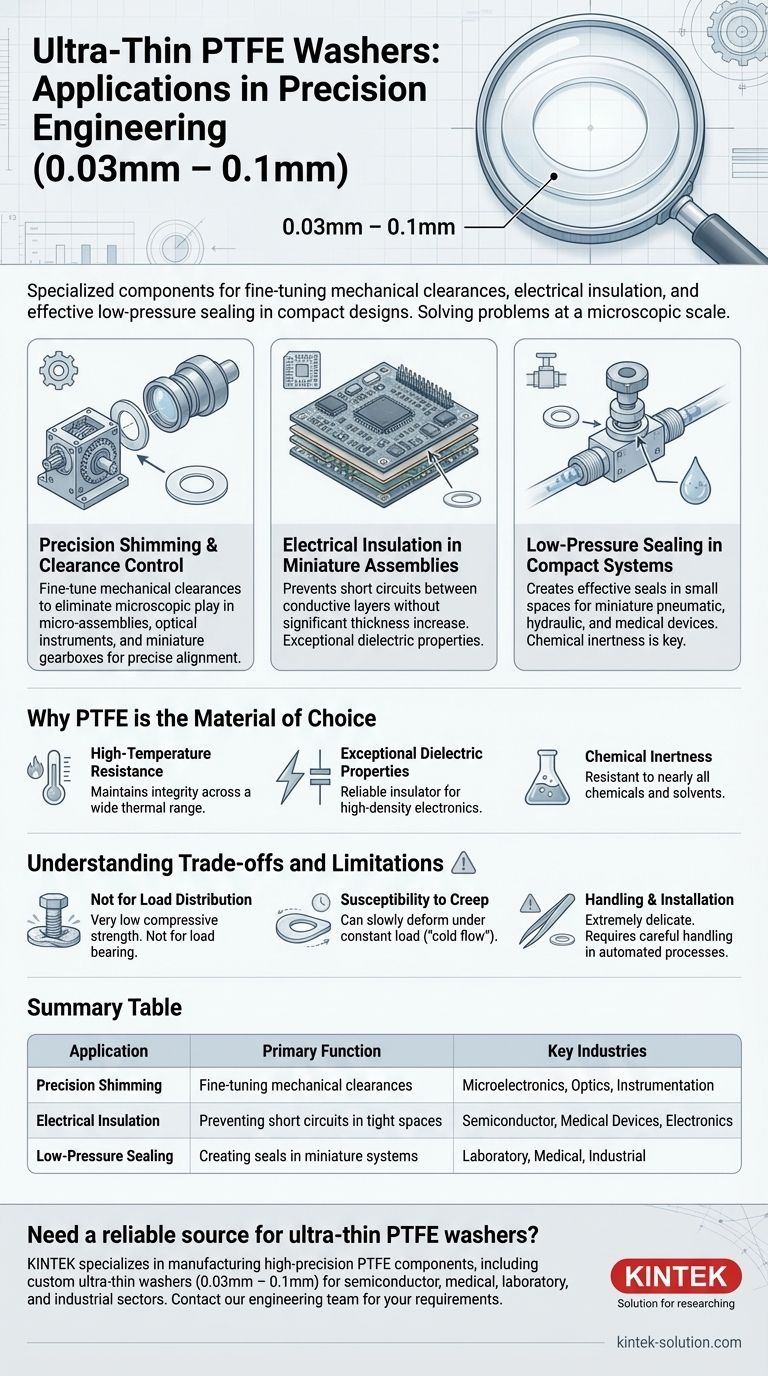

The Core Functions of Ultra-Thin PTFE

The applications for these washers are defined by scenarios where minimal thickness is a non-negotiable design constraint. They function less like traditional load-bearing washers and more like precision-engineered films.

Precision Shimming and Clearance Control

In micro-assemblies, even minuscule gaps can impact performance. Ultra-thin washers act as precision shims to eliminate this unwanted play.

This is critical in applications like microelectronics, optical instrument alignment, or miniature gearboxes where precise axial positioning is essential for proper function.

Electrical Insulation in Miniature Assemblies

PTFE is an exceptional dielectric material, meaning it does not conduct electricity. This property is vital in tightly packed electronic components.

An ultra-thin washer can be placed between conductive layers or components on a printed circuit board (PCB) to prevent short circuits without significantly increasing the assembly's overall thickness.

Low-Pressure Sealing in Compact Systems

The inherent softness and chemical inertness of PTFE make it an excellent sealing material. When fabricated into an ultra-thin washer, it can create a seal in very small spaces.

These are ideal for sealing connections in miniature pneumatic or hydraulic systems, medical devices, or laboratory equipment where pressures are low and space is at a premium.

Why PTFE is the Material of Choice

The selection of Polytetrafluoroethylene (PTFE) is not arbitrary. Its inherent material properties make it uniquely suited for these demanding applications, especially when manufactured to such fine tolerances.

High-Temperature Resistance

PTFE maintains its integrity across a wide temperature range, making it suitable for electronics and other components that experience thermal cycling.

Exceptional Dielectric Properties

As one of the best-known insulators, PTFE is a reliable choice for preventing electrical arcing or leakage in compact, high-density electronic designs.

Chemical Inertness

PTFE is resistant to nearly all chemicals and solvents. This allows these thin washers to be used in aggressive environments, from industrial processing to food-grade applications with harsh cleaning agents.

Understanding the Trade-offs and Limitations

To use these components effectively, it is critical to understand their limitations. Misapplication is a common source of failure.

Not for Load Distribution

Unlike standard, thicker washers, ultra-thin PTFE washers have very low compressive strength. They cannot be used to distribute the load of a screw or bolt and will be easily crushed under significant torque.

Susceptibility to Creep

PTFE is known to exhibit "creep" or cold flow, meaning it can slowly deform over time under a constant load. This must be accounted for in any design where consistent clamping force is required.

Handling and Installation

A washer with a thickness of 0.03mm is extremely delicate and can be challenging to handle and install, especially in automated assembly processes. Care must be taken to avoid tearing or deforming the part.

Making the Right Choice for Your Application

Selecting an ultra-thin PTFE washer requires a clear understanding of your primary engineering goal.

- If your primary focus is precise mechanical spacing: Use these washers as shims to eliminate microscopic play in sensitive assemblies like optical mounts or micro-gearboxes.

- If your primary focus is electrical insulation: Employ these washers to prevent short circuits between layers on densely packed printed circuit boards (PCBs) and sensors.

- If your primary focus is low-pressure sealing: Integrate them into miniature valves or fluidic systems where a compliant seal is needed without altering critical assembly dimensions.

By understanding these specific applications and material limitations, you can leverage ultra-thin PTFE washers to solve complex engineering challenges at a microscopic scale.

Summary Table:

| Application | Primary Function | Key Industries |

|---|---|---|

| Precision Shimming | Fine-tuning mechanical clearances | Microelectronics, Optics, Instrumentation |

| Electrical Insulation | Preventing short circuits in tight spaces | Semiconductor, Medical Devices, Electronics |

| Low-Pressure Sealing | Creating seals in miniature systems | Laboratory, Medical, Industrial |

Need a reliable source for ultra-thin PTFE washers?

KINTEK specializes in manufacturing high-precision PTFE components, including custom ultra-thin washers, for the semiconductor, medical, laboratory, and industrial sectors. We ensure the material integrity and exact tolerances (0.03mm – 0.1mm) your micro-assemblies demand, from prototypes to high-volume production.

Contact our engineering team today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance