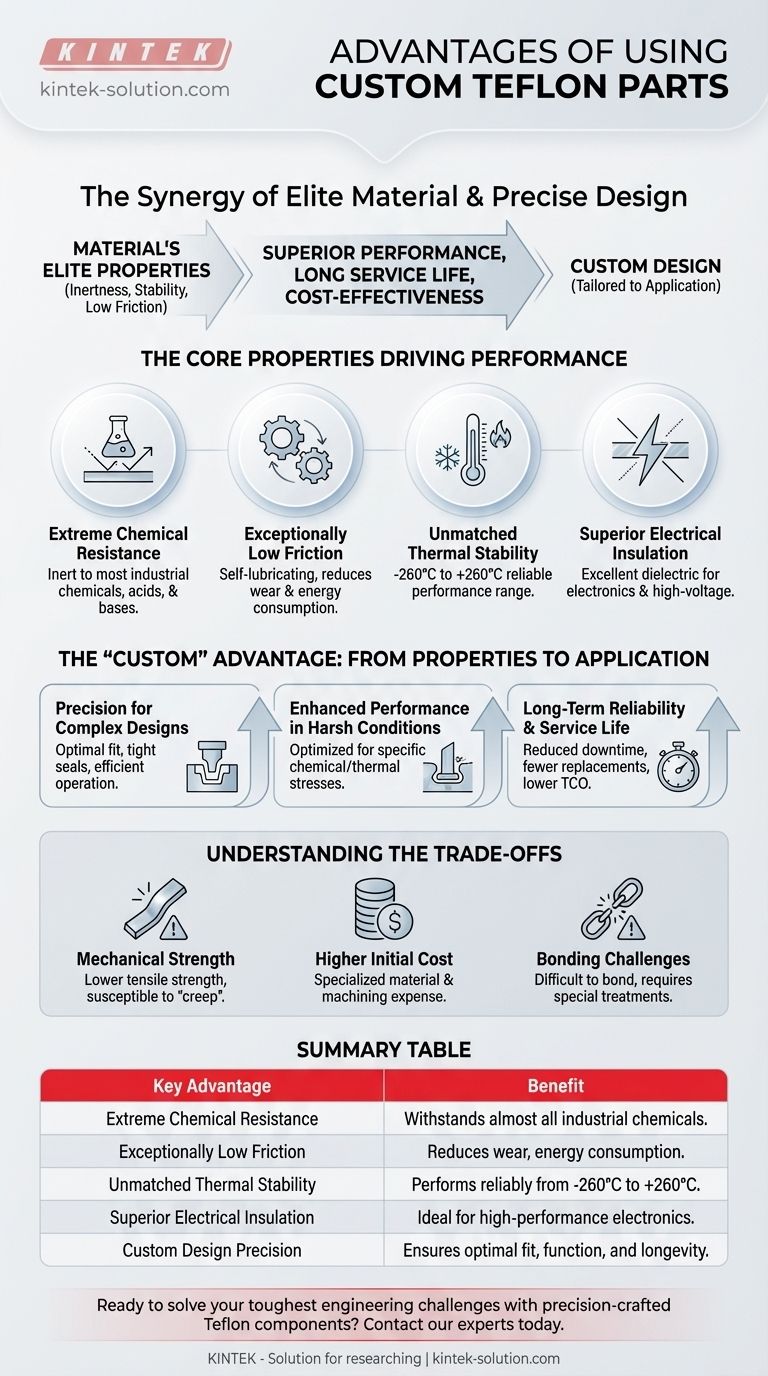

At its core, the advantage of using custom Teflon parts lies in combining the material's elite inherent properties—chemical inertness, thermal stability, and low friction—with a design tailored precisely to a specific, demanding application. This synergy results in components that offer superior performance, a long service life, and long-term cost-effectiveness in environments where generic materials would quickly fail.

The true value of custom Teflon (PTFE) is not just in the material itself, but in the ability to engineer its unique characteristics into a precise form factor. This unlocks solutions for extreme operational challenges that are unattainable with off-the-shelf components.

The Core Properties Driving Performance

The benefits of Teflon are a direct result of its fundamental material characteristics. Understanding these properties is key to understanding its value in custom applications.

### Extreme Chemical Resistance

Teflon, or PTFE, is virtually inert to almost all industrial chemicals, acids, and bases. This makes it an essential material for seals, gaskets, and linings in corrosive environments.

### Exceptionally Low Friction

With one of the lowest coefficients of friction of any solid material, Teflon components are naturally self-lubricating. This dramatically reduces wear and energy consumption in moving parts like bearings, gears, and slide plates.

### Unmatched Thermal Stability

Custom Teflon parts perform reliably across an exceptionally wide temperature range, typically from -260°C to +260°C (-436°F to +500°F). They will not become brittle in cryogenic conditions or degrade in high-heat applications.

### Superior Electrical Insulation

Teflon possesses excellent dielectric properties, meaning it does not conduct electricity. This makes it an ideal choice for manufacturing high-performance insulators and components for electronics and high-voltage equipment.

The "Custom" Advantage: From Properties to Application

While Teflon's properties are impressive, customization is what translates that potential into a specific engineering solution, enhancing performance and longevity.

### Precision for Complex Designs

The ability to machine Teflon into custom shapes allows for the creation of parts that fit perfectly within a complex assembly. This ensures optimal function, tight seals, and efficient operation that generic parts cannot provide.

### Enhanced Performance in Harsh Conditions

A custom-designed part leverages Teflon's inherent strengths to their fullest. The design can be optimized to withstand specific chemical exposures, temperature cycles, or mechanical stresses unique to your operational environment.

### Long-Term Reliability and Service Life

Because a custom part is engineered for a specific purpose using a highly durable material, it lasts significantly longer. This leads to reduced downtime, fewer replacement cycles, and a lower total cost of ownership over the product's lifecycle.

Understanding the Trade-offs

To make an informed decision, it is critical to recognize Teflon's limitations. Its unique properties come with specific engineering considerations.

### Mechanical Strength Limitations

Compared to engineering plastics like PEEK or metals, Teflon is a relatively soft material. It can be susceptible to "creep," or deformation under sustained load, and has lower tensile strength.

### Higher Initial Cost

The raw material and specialized machining required for custom Teflon parts often result in a higher upfront cost compared to components made from more common materials like nylon or acetal.

### Bonding and Adhesion Challenges

Teflon's non-stick, low-friction surface makes it very difficult to bond to other materials using conventional adhesives. This requires special surface treatments if adhesion is a design requirement.

Making the Right Choice for Your Goal

Selecting the right material depends entirely on the primary objective of your component.

- If your primary focus is reliability in extreme chemical or thermal environments: Custom Teflon is an unparalleled choice for its inertness and stability.

- If your primary focus is reducing wear and friction in moving parts: Teflon's self-lubricating nature provides a significant performance advantage.

- If your primary focus is high structural strength or low initial cost: You should carefully evaluate whether Teflon's benefits outweigh its mechanical limitations and upfront expense.

Ultimately, choosing custom Teflon is an investment in specialized performance for critical applications.

Summary Table:

| Key Advantage | Benefit |

|---|---|

| Extreme Chemical Resistance | Withstands almost all industrial chemicals, acids, and bases. |

| Exceptionally Low Friction | Self-lubricating, reduces wear and energy consumption. |

| Unmatched Thermal Stability | Performs reliably from -260°C to +260°C. |

| Superior Electrical Insulation | Ideal for high-performance insulators and electronics. |

| Custom Design Precision | Ensures optimal fit, function, and longevity for specific applications. |

Ready to solve your toughest engineering challenges with precision-crafted Teflon components?

At KINTEK, we specialize in manufacturing high-performance custom PTFE parts—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We combine the elite properties of Teflon with expert custom fabrication, from prototypes to high-volume orders, to deliver the reliability and cost-effectiveness your application demands.

Contact our experts today to discuss your custom Teflon solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does the chemical resistance of custom Teflon rotary shaft seals benefit industrial applications? Ensure Unmatched Reliability in Harsh Environments

- What are the characteristics of Teflon washers? Unlock Superior Slipperiness & Chemical Resistance

- What future advancements are expected for PTFE oil seals? From Smart Seals to 3D Printing

- What is the thermal shock method for cleaning Teflon residue? Safely Remove Stubborn PTFE Buildup

- How do PTFE seals contribute to reducing vehicle emissions? Achieve Cleaner, More Efficient Vehicles

- What are the three types of reinforcements in PTFE-based materials? Choose the Right Material for Your Application

- What are the advantages of polyester-filled PTFE? A Guide to Superior Wear & Load Performance

- What are the main advantages of using PTFE over rubber in rotary shaft seals? Superior Performance in Extreme Conditions