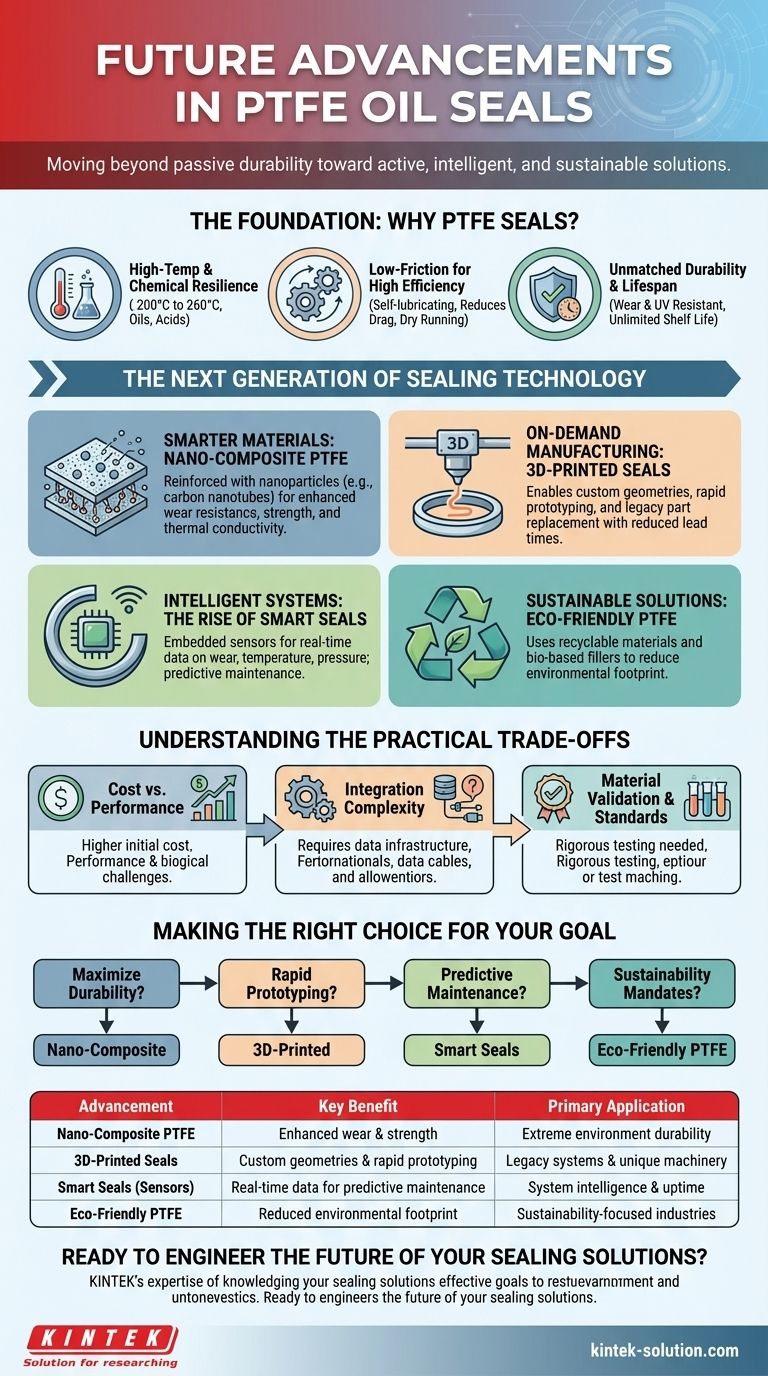

Looking ahead, the future of PTFE oil seals is moving beyond passive durability and toward active, intelligent, and sustainable solutions. The primary advancements expected are the development of nano-composites for enhanced strength, the use of 3D printing for custom applications, the integration of sensors to create "smart" seals, and the adoption of eco-friendly materials and manufacturing processes.

The evolution of PTFE seals is a shift from high-performance components to highly specialized, data-driven system assets. The focus is no longer just on withstanding harsh conditions but on providing tailored performance, real-time feedback, and greater sustainability.

The Foundation: Why PTFE Seals are a Critical Component

Before exploring future trends, it's essential to understand why PTFE (Polytetrafluoroethylene) is such a dominant material for high-performance seals today. Its inherent properties create a benchmark that new innovations must exceed.

High-Temperature and Chemical Resilience

PTFE seals operate effectively in extreme temperature ranges, typically from -200°C to 260°C (-328°F to 500°F).

They also offer exceptional resistance to aggressive chemicals, including oils, acids, solvents, and other corrosive fluids, making them indispensable in chemical processing and automotive applications.

Low-Friction for High Efficiency

The material's extremely low coefficient of friction means it is self-lubricating. This quality reduces rotational drag, minimizes energy loss, and significantly extends the service life of both the seal and the shaft.

This property also makes PTFE seals suitable for dry running applications where traditional lubrication is not feasible.

Unmatched Durability and Lifespan

PTFE seals are highly durable, resisting wear and environmental factors like moisture and UV rays.

When stored correctly, they have a virtually unlimited shelf life, providing a distinct advantage in logistics and long-term parts management for critical industries like aerospace and defense.

The Next Generation of Sealing Technology

Future advancements are focused on overcoming the limitations of traditional PTFE and adding entirely new capabilities. These innovations address the growing demands for higher efficiency, predictive maintenance, and environmental responsibility.

Smarter Materials: Nano-Composite PTFE

This involves reinforcing the base PTFE material with nanoparticles, such as carbon nanotubes.

The primary goal is to significantly improve mechanical properties like wear resistance, strength, and thermal conductivity without sacrificing PTFE's low friction or chemical inertness. This allows for seals that last longer in even more demanding conditions.

On-Demand Manufacturing: 3D-Printed Seals

Additive manufacturing will enable the creation of highly customized seals with complex geometries on demand.

This is a game-changer for prototyping, legacy equipment repair, and specialized machinery where off-the-shelf seals are not an option. It dramatically reduces lead times for unique parts.

Intelligent Systems: The Rise of Smart Seals

The most significant leap forward is the integration of embedded sensors directly into the seal.

These "smart seals" can provide real-time data on wear, temperature, and pressure. This transforms the seal from a passive component into an active part of a predictive maintenance system, helping to prevent catastrophic failures by signaling when a replacement is needed.

Sustainable Solutions: Eco-Friendly PTFE

In response to growing environmental concerns, research is focused on more sustainable options.

This includes developing processes for using recyclable PTFE and incorporating bio-based fillers, like bamboo fiber, to reduce the environmental footprint without compromising performance.

Understanding the Practical Trade-offs

While these advancements are promising, their adoption will require careful consideration of new challenges and costs. True expertise means recognizing both the potential and the pitfalls.

Cost vs. Performance

Advanced materials like nano-composites and the technology required for smart seals will initially be significantly more expensive than traditional PTFE. The decision to adopt them will require a clear return-on-investment analysis based on extended lifespan or failure prevention.

Integration Complexity

A smart seal is not a simple drop-in replacement. It is part of a larger data ecosystem. Implementing them successfully requires an infrastructure for powering sensors, transmitting data, and analyzing the results, which adds a layer of engineering complexity.

Material Validation and Standards

New material formulations, especially nano-composites and bio-fillers, will need to undergo rigorous testing and certification. This is particularly critical in highly regulated industries like aerospace, food, and pharmaceuticals, where material purity and reliability are non-negotiable.

Making the Right Choice for Your Goal

As these technologies mature, selecting the right seal will depend entirely on your primary engineering or business objective.

- If your primary focus is maximizing durability and uptime in extreme environments: Keep a close watch on the development and availability of nano-composite PTFE seals.

- If your primary focus is rapid prototyping or supporting legacy systems: Begin exploring partnerships with manufacturers who are developing 3D-printing capabilities for seals.

- If your primary focus is predictive maintenance and system intelligence: Start planning the data and hardware infrastructure required to support the adoption of smart seals.

- If your primary focus is meeting corporate sustainability mandates: Engage with suppliers about their roadmap for recyclable materials and bio-filled PTFE compounds.

By understanding these trends, you can transition from simply selecting components to strategically engineering more resilient, efficient, and intelligent systems.

Summary Table:

| Advancement | Key Benefit | Primary Application |

|---|---|---|

| Nano-Composite PTFE | Enhanced wear resistance & strength | Extreme environment durability |

| 3D-Printed Seals | Custom geometries & rapid prototyping | Legacy systems & unique machinery |

| Smart Seals (Sensors) | Real-time data for predictive maintenance | System intelligence & uptime |

| Eco-Friendly PTFE | Reduced environmental footprint | Sustainability-focused industries |

Ready to engineer the future of your sealing solutions?

As these advancements in PTFE technology evolve, partnering with an expert manufacturer is key to leveraging their benefits. KINTEK specializes in the precision production of high-performance PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We offer custom fabrication from prototypes to high-volume orders, ensuring your systems are equipped with the most durable and efficient components.

Let's discuss how our expertise can help you integrate next-generation sealing technology for more resilient and intelligent operations.

Contact KINTEK today for a consultation.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are some common PTFE seal types used in industrial applications? Explore Solutions for Every Motion & Environment

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C