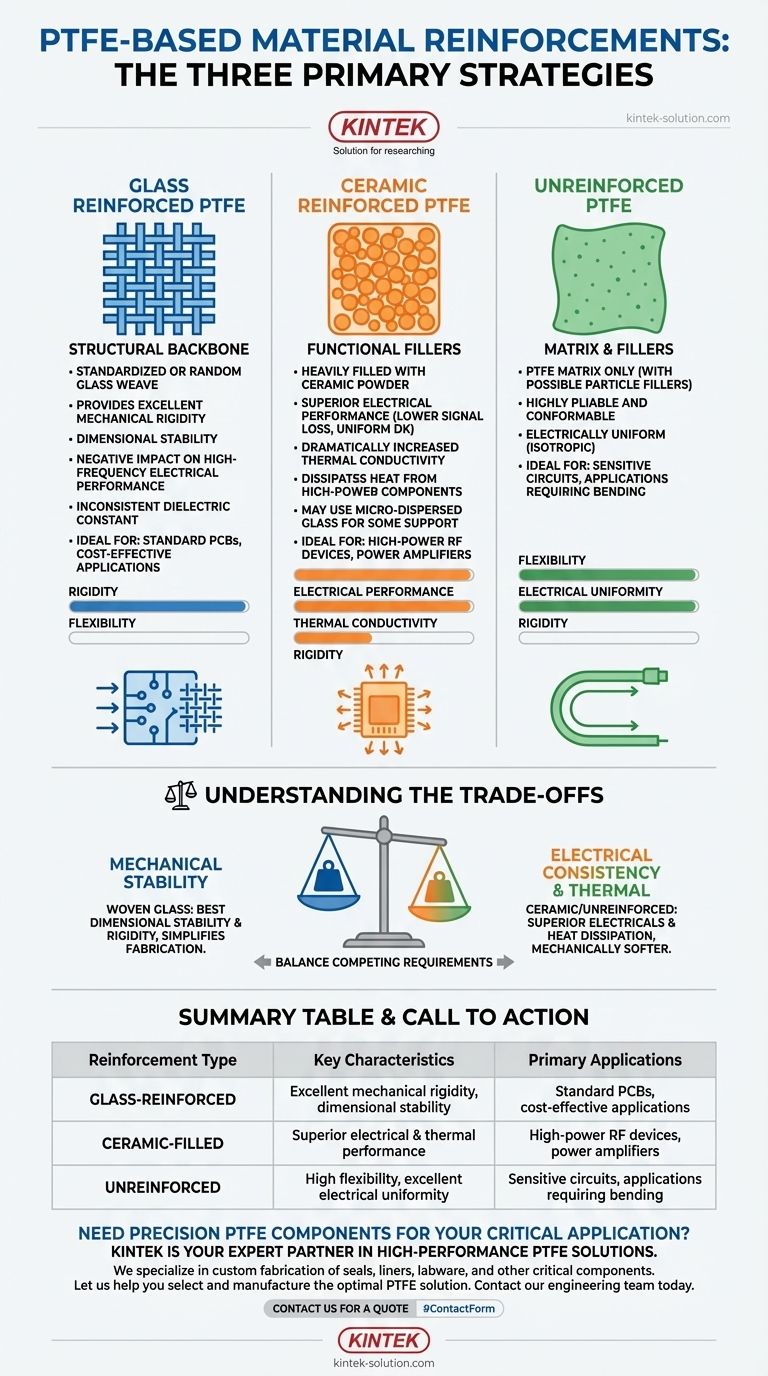

In PTFE-based materials, there are three primary reinforcement strategies: glass reinforced, ceramic reinforced, and unreinforced. Glass reinforcement uses a standardized or random glass weave to provide significant rigidity. Ceramic reinforcement typically involves adding ceramic fillers to tailor electrical and thermal properties. Unreinforced materials consist of only the PTFE matrix, often with particle fillers, making them highly pliable and electrically uniform.

The choice of reinforcement is not just about mechanical strength; it is the fundamental decision that dictates the material's electrical performance, thermal stability, and suitability for a specific application, especially in high-frequency electronics.

The Critical Distinction: Reinforcements vs. Fillers

To properly understand these materials, it's essential to distinguish between a structural reinforcement and a functional filler. They serve different primary purposes.

Reinforcements Provide Structural Integrity

A reinforcement is typically a fabric or fiber weave, like woven glass. Its main job is to provide mechanical strength, rigidity, and dimensional stability to the otherwise soft PTFE matrix.

This structural backbone prevents the material from warping or changing shape during fabrication and under thermal stress.

Fillers Modify Core Properties

A filler is usually a powder mixed into the PTFE resin before it's formed. Its main job is to modify the inherent properties of the PTFE.

Ceramics are the most common fillers. They are added to control the dielectric constant (Dk), reduce electrical loss, and significantly improve thermal conductivity, helping to dissipate heat.

A Deeper Look at Each Reinforcement Type

Each reinforcement strategy creates a material with a distinct profile of strengths and weaknesses.

Glass-Reinforced PTFE

This is the most traditional composite structure, where a woven glass fabric is impregnated with PTFE. It is a standard choice for many printed circuit board (PCB) applications.

The key advantage is excellent mechanical stability. The glass weave makes the material rigid and easy to handle during manufacturing. Common glass weaves include types like 106, 1078, and 1080.

However, the glass weave can negatively impact high-frequency electrical performance by introducing inconsistencies in the dielectric constant across the material.

Ceramic-Filled PTFE

These materials prioritize electrical and thermal performance. They consist of a PTFE matrix heavily filled with ceramic powder.

Their primary benefit is superior electrical performance, including lower signal loss and a more uniform, isotropic dielectric constant because there is no coarse weave pattern.

The ceramic fillers also dramatically increase thermal conductivity, which is critical for dissipating heat from high-power components. While sometimes unreinforced, these materials often use a very light, micro-dispersed glass for some structural support without compromising electricals.

Unreinforced PTFE

This category represents PTFE in its most pliable form. It consists of the PTFE matrix, which may or may not contain functional fillers like ceramic powder.

The defining characteristic is flexibility and conformity. Without a structural weave, the material is very soft and can be used in applications requiring bending.

Electrically, it is highly uniform (isotropic) as there is no glass weave to influence signal propagation. This makes it ideal for applications where electrical consistency is the absolute priority.

Understanding the Trade-offs

Choosing a material involves balancing competing requirements. There is no single "best" option; only the best fit for a specific design goal.

Mechanical Stability vs. Electrical Consistency

Woven glass provides the best dimensional stability and rigidity, which simplifies PCB manufacturing. However, the glass fibers and PTFE resin have different dielectric constants, creating electrical inconsistencies that can be problematic for very high-frequency or sensitive designs.

Ceramic-filled and unreinforced materials offer far superior electrical consistency but are mechanically softer, which can present challenges in fabrication.

Thermal Management

Standard glass-reinforced PTFE is a poor thermal conductor. The addition of ceramic fillers provides a significant improvement, creating a direct path for heat to escape from active components to a heat sink. This is a critical advantage for power amplifiers and other high-power RF devices.

Cost and Complexity

Glass-reinforced materials are generally the most mature and cost-effective option. High-performance ceramic-filled composites are typically more expensive due to the advanced materials and processes involved.

Making the Right Choice for Your Application

Your final decision should be guided by the single most critical performance parameter of your design.

- If your primary focus is mechanical rigidity and cost-effectiveness for general-purpose applications: Choose a standard glass-reinforced PTFE material.

- If your primary focus is superior high-frequency electrical performance and thermal management: Opt for a ceramic-filled PTFE composite.

- If your primary focus is flexibility or absolute electrical uniformity for highly sensitive circuits: An unreinforced PTFE, which may still contain ceramic fillers for dielectric control, is the ideal choice.

Understanding these reinforcement strategies allows you to precisely match your material to your design's unique mechanical, thermal, and electrical demands.

Summary Table:

| Reinforcement Type | Key Characteristics | Primary Applications |

|---|---|---|

| Glass-Reinforced | Excellent mechanical rigidity, dimensional stability | Standard PCBs, cost-effective applications |

| Ceramic-Filled | Superior high-frequency electrical performance, high thermal conductivity | High-power RF devices, power amplifiers |

| Unreinforced | High flexibility, excellent electrical uniformity, pliable | Sensitive circuits, applications requiring bending |

Need Precision PTFE Components for Your Critical Application?

Choosing the right PTFE material is essential for the success of your project in the semiconductor, medical, laboratory, or industrial sectors. The wrong material can lead to performance issues, manufacturing delays, and increased costs.

KINTEK is your expert partner in high-performance PTFE solutions. We don't just supply parts; we provide material expertise and precision manufacturing to ensure your components meet the exact mechanical, thermal, and electrical demands of your application.

We specialize in the custom fabrication of PTFE seals, liners, labware, and other critical components—from initial prototypes to high-volume production runs. Our focus on precision ensures your designs perform reliably.

Let us help you select and manufacture the optimal PTFE solution. Contact our engineering team today to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech