In furniture, Teflon is primarily used in two ways: as a key component in furniture sliders to protect floors and as a protective, stain-resistant coating for fabrics and upholstery. These applications leverage Teflon's unique properties of being extremely low-friction and chemically non-reactive, which prevents materials from sticking to it.

The core value of Teflon in household furniture is not in the structure of the piece itself, but in how it enhances the interaction between the furniture and its environment—either by allowing it to move without causing damage or by protecting it from everyday spills and stains.

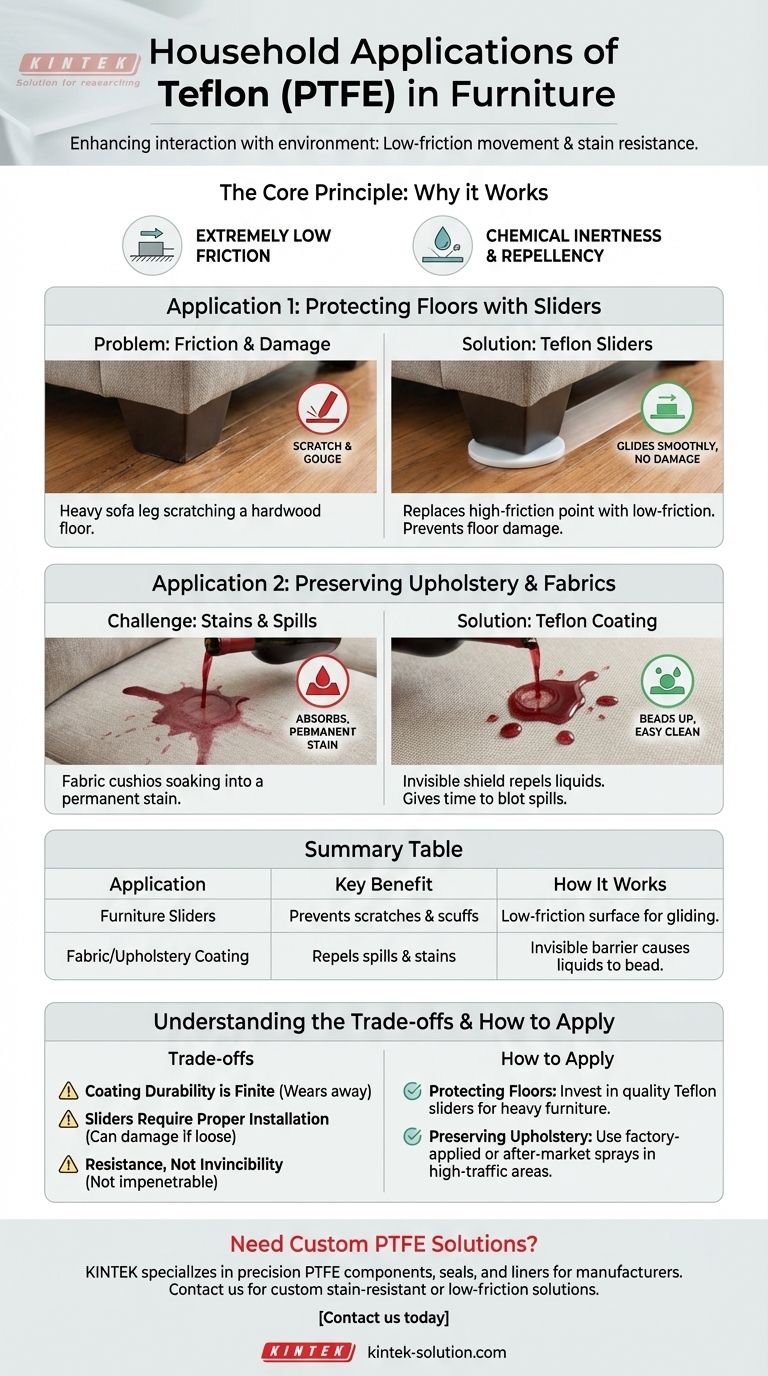

The Core Principle: Why Teflon Is So Effective

To understand its applications, it’s essential to grasp the two fundamental properties of Polytetrafluoroethylene (PTFE), the chemical compound known by the brand name Teflon.

Extremely Low Friction

Teflon has one of the lowest coefficients of friction of any solid material known. This means surfaces slide past each other with almost no resistance. It’s what makes a frying pan "non-stick" and allows a heavy sofa to glide across a floor.

Chemical Inertness and Repellency

Teflon is chemically inert and non-porous. This property means that other substances, particularly liquids like water or oil, do not easily bond with or soak into its surface. Instead, they bead up and can be wiped away, which is the basis for its use as a stain repellent.

Application 1: Protecting Floors with Furniture Sliders

The most common and direct application of Teflon in furniture is in sliders, which are small discs or pads placed on the feet of furniture.

The Problem of Friction and Damage

Heavy furniture like couches, tables, and entertainment centers can easily scratch, scuff, or gouge sensitive flooring materials like hardwood, laminate, or vinyl during movement. The friction between the furniture leg and the floor surface is the direct cause of this damage.

How Teflon Sliders Provide a Solution

By placing a Teflon slider under a furniture leg, you replace the high-friction contact point with an extremely low-friction one. This allows even very heavy items to be moved with minimal effort. The furniture glides smoothly across the floor instead of scraping against it, preventing damage.

Application 2: Preserving Upholstery and Fabrics

Teflon's second key application is as an invisible shield for textiles used in furniture, such as cushions, pillows, and even blankets.

The Challenge of Stains and Spills

Fabrics are naturally porous and absorbent. When a liquid like wine, coffee, or juice is spilled, the fibers quickly soak it up, leading to a permanent stain that is difficult or impossible to remove.

Teflon as a Protective Fabric Coating

When applied as a treatment, Teflon creates a microscopic, protective layer around the fabric's fibers. This coating does not change the look or feel of the material, but it leverages Teflon's liquid-repelling properties. Spills bead up on the surface rather than soaking in, giving you time to blot them away before they can set.

Understanding the Trade-offs

While highly effective, it's important to recognize the limitations of these applications to set realistic expectations.

Coating Durability is Finite

On fabrics, the Teflon coating is not permanent. It can gradually wear away with heavy use, abrasion, and frequent or improper cleaning. Over time, its effectiveness as a stain repellent will diminish.

Sliders Require Proper Installation

For furniture sliders to work, they must be clean and securely attached. If a self-adhesive slider comes loose or a tap-in slider breaks, the exposed adhesive or nail can cause significant damage to the floor—defeating its very purpose.

Resistance, Not Invincibility

A Teflon coating provides stain resistance, not a completely impenetrable barrier. A spill left to sit for an extended period, especially if it's hot or oily, may eventually penetrate the protective layer.

How to Apply This to Your Home

Your choice depends entirely on your specific goal for protecting your furniture and home.

- If your primary focus is protecting floors: Invest in high-quality Teflon sliders for any heavy or frequently moved furniture, especially on hardwood, vinyl, or laminate surfaces.

- If your primary focus is preserving new or delicate upholstery: Consider purchasing furniture that comes with a factory-applied fabric protectant or use an after-market Teflon-based spray for items in high-traffic areas.

Ultimately, using Teflon in these small but strategic ways is an effective method for extending the life and appearance of both your furniture and your floors.

Summary Table:

| Application | Key Benefit | How It Works |

|---|---|---|

| Furniture Sliders | Prevents floor scratches & scuffs | Teflon pads create a low-friction surface for smooth gliding |

| Fabric/Upholstery Coating | Repels spills & stains | Forms invisible barrier causing liquids to bead up for easy wiping |

Need Custom PTFE Solutions for Your Products?

As a leading manufacturer of precision PTFE components, KINTEK specializes in creating custom Teflon seals, liners, and specialized parts for furniture manufacturers, industrial applications, and more. Whether you require prototypes or high-volume production, our expertise in PTFE fabrication ensures superior performance for your stain-resistant coatings or low-friction components.

Contact us today to discuss how we can enhance your product with durable, custom PTFE solutions!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key benefits of PTFE oil seals? Superior Performance in Extreme Conditions

- What type of sealing is used for the ball shaft in PTFE ball valves? Discover the Maintenance-Free V-Ring System

- How should Teflon O-rings be maintained? A Proactive Guide to Prevent Seal Failure

- How does Teflon benefit the chemical processing industry? Enhance Safety, Purity, and Equipment Life

- What are some industrial and niche applications of PTFE coatings? Solve Your Toughest Corrosion and Friction Problems

- What temperature range can PTFE expansion bellows withstand? Endure Extremes from -200°C to 260°C

- What is the correct method for installing PTFE wear plates? Achieve Long-Lasting, Low-Friction Performance

- What are the key advantages of PTFE slide bearings in construction? Achieve Maintenance-Free Structural Movement