The primary benefits of PTFE oil seals stem from their unique material properties, which deliver superior performance in extreme conditions where traditional elastomer seals would fail. These core advantages include exceptional chemical resistance, a very wide operational temperature range, and an extremely low coefficient of friction.

PTFE seals are not just an alternative to rubber seals; they are a specialized engineering solution. Their value lies in providing unparalleled reliability in harsh chemical, thermal, and high-speed environments, ultimately reducing long-term maintenance costs and system downtime.

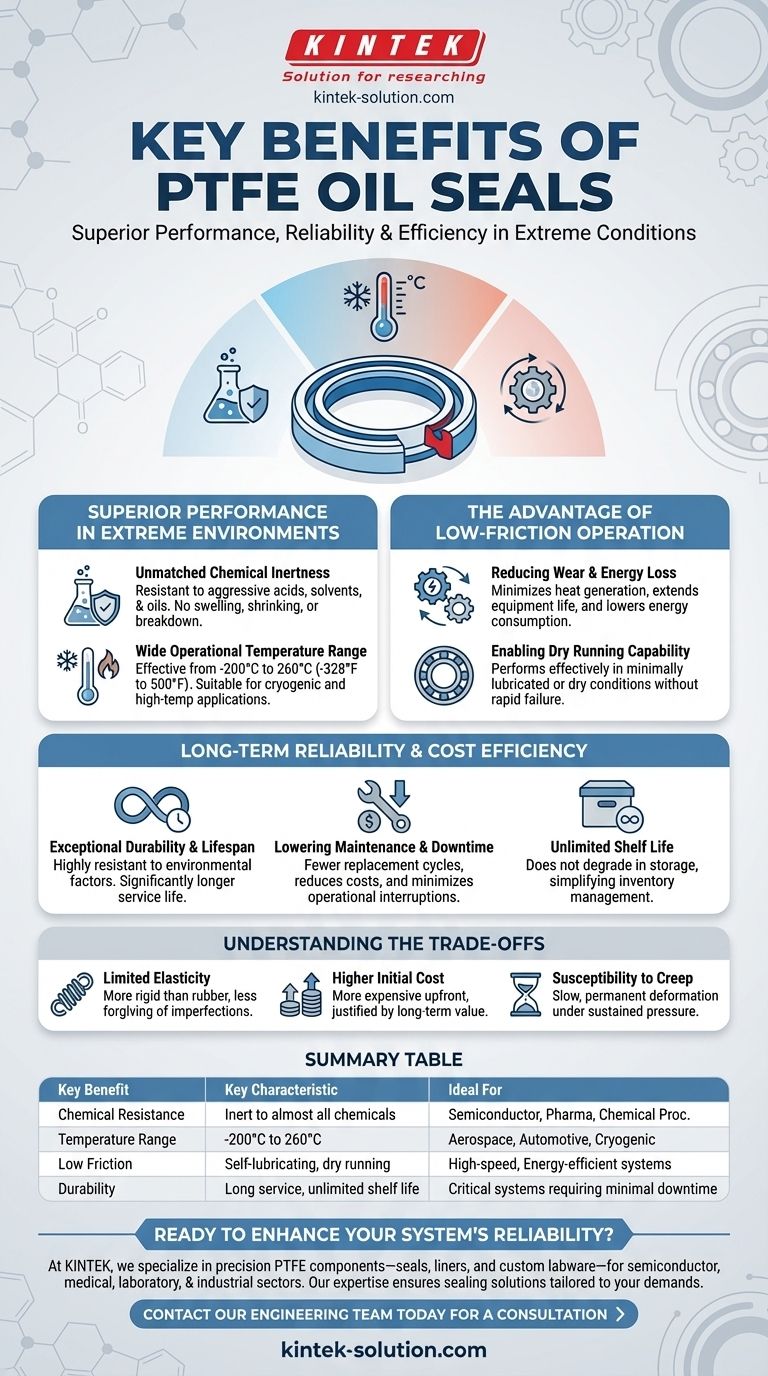

Superior Performance in Extreme Environments

The fundamental advantage of Polytetrafluoroethylene (PTFE) is its ability to maintain integrity under conditions that would cause other materials to degrade rapidly. This makes it a critical component in demanding industries like aerospace, chemical processing, and automotive manufacturing.

Unmatched Chemical Inertness

PTFE is inert to almost all industrial chemicals, including aggressive acids, solvents, and oils. This makes it the default choice for applications in the pharmaceutical and semiconductor industries, where seal failure due to chemical attack is not an option.

Unlike many rubber compounds, a PTFE sealing lip will not swell, shrink, or break down when exposed to corrosive fluids, ensuring consistent performance.

Wide Operational Temperature Range

PTFE seals operate effectively across an exceptionally broad temperature spectrum, typically from -200°C to 260°C (-328°F to 500°F).

This thermal stability allows them to be used in high-temperature applications like engines and transmissions, as well as cryogenic systems, where standard elastomers would become brittle and crack.

The Advantage of Low-Friction Operation

The molecular structure of PTFE gives it one of the lowest coefficients of friction of any solid material. This self-lubricating property has profound impacts on performance and efficiency.

Reducing Wear and Energy Loss

The low-friction surface minimizes heat generation at the contact point, even at high rotational speeds. This reduces wear on the shaft, extends the service life of both the seal and the equipment, and lowers overall energy consumption.

Enabling Dry Running Capability

A key differentiator is PTFE's ability to perform in dry running or minimally lubricated conditions. While most elastomer seals require a constant film of oil to prevent overheating and rapid failure, PTFE seals can operate effectively without it.

Long-Term Reliability and Cost Efficiency

While the initial cost of a PTFE seal may be higher than a standard alternative, its durability translates directly into a lower total cost of ownership over the equipment's lifespan.

Exceptional Durability and Lifespan

PTFE is highly resistant to environmental factors such as moisture and UV radiation, preventing degradation over time. This robust nature, combined with its wear resistance, leads to a significantly longer service life compared to most other seal materials.

Lowering Maintenance and Downtime

The extended lifespan of PTFE seals means fewer replacement cycles are necessary. This directly reduces maintenance costs, minimizes costly operational downtime, and improves the overall reliability of the machinery.

Unlimited Shelf Life

Unlike rubber seals that can degrade over time in storage, PTFE seals are not subject to aging. They have an unlimited shelf life, which simplifies inventory management and ensures a component is ready for service whenever needed.

Understanding the Trade-offs of PTFE

To make an informed decision, it is critical to understand the limitations of PTFE. It is not a universal solution, and its properties come with specific trade-offs.

Limited Elasticity

Compared to rubber elastomers, PTFE is a much more rigid material. It has very little "memory" and does not rebound as effectively. This can make installation more challenging and makes the seal less forgiving of shaft imperfections or significant runout.

Higher Initial Cost

PTFE seals are generally more expensive upfront than their common nitrile or FKM (Viton) counterparts. Their value is justified in applications where the cost of failure or frequent maintenance is far greater than the initial component cost.

Susceptibility to Creep

Under sustained pressure and high temperatures, PTFE can be subject to "creep," which is a slow, permanent deformation. Seal and hardware design must account for this characteristic to ensure a reliable long-term seal.

Making the Right Choice for Your Application

Selecting the correct seal material is an engineering decision based on the specific demands of the system.

- If your primary focus is handling aggressive chemicals or extreme temperatures: PTFE is the definitive choice where standard elastomers would degrade and fail.

- If your primary focus is maximizing efficiency in high-speed or dry running conditions: The inherent low friction of PTFE reduces energy loss and allows for reliable operation without lubrication.

- If your primary focus is minimizing long-term maintenance costs in a critical system: The durability of PTFE seals often justifies the higher initial investment by significantly reducing downtime and replacement frequency.

Ultimately, selecting a PTFE seal is a strategic decision to prioritize long-term system reliability in demanding operational conditions.

Summary Table:

| Key Benefit | Key Characteristic | Ideal For |

|---|---|---|

| Chemical Resistance | Inert to almost all industrial chemicals | Semiconductor, Pharmaceutical, Chemical Processing |

| Temperature Range | Operates from -200°C to 260°C | Aerospace, Automotive, Cryogenic Systems |

| Low Friction | Self-lubricating, enables dry running | High-speed applications, Energy-efficient systems |

| Durability | Long service life, unlimited shelf life | Critical systems requiring minimal downtime |

Ready to enhance your system's reliability with high-performance PTFE seals?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get a sealing solution tailored to your specific operational demands.

Let us help you reduce maintenance costs, minimize downtime, and achieve superior performance in even the most extreme conditions. Contact our engineering team today for a consultation on your PTFE sealing requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments