In short, Teflon (PTFE) square bars are a versatile stock material machined into high-performance components for demanding environments. Their most common applications are creating custom seals, gaskets, bearings, and electrical insulators for industries like chemical processing, aerospace, and food manufacturing where chemical inertness, low friction, and high-temperature resistance are critical.

Teflon square bars are rarely the final product. Instead, they serve as the raw material for fabricating custom parts that solve extreme engineering challenges where other materials would fail due to chemical attack, friction, or electrical demands.

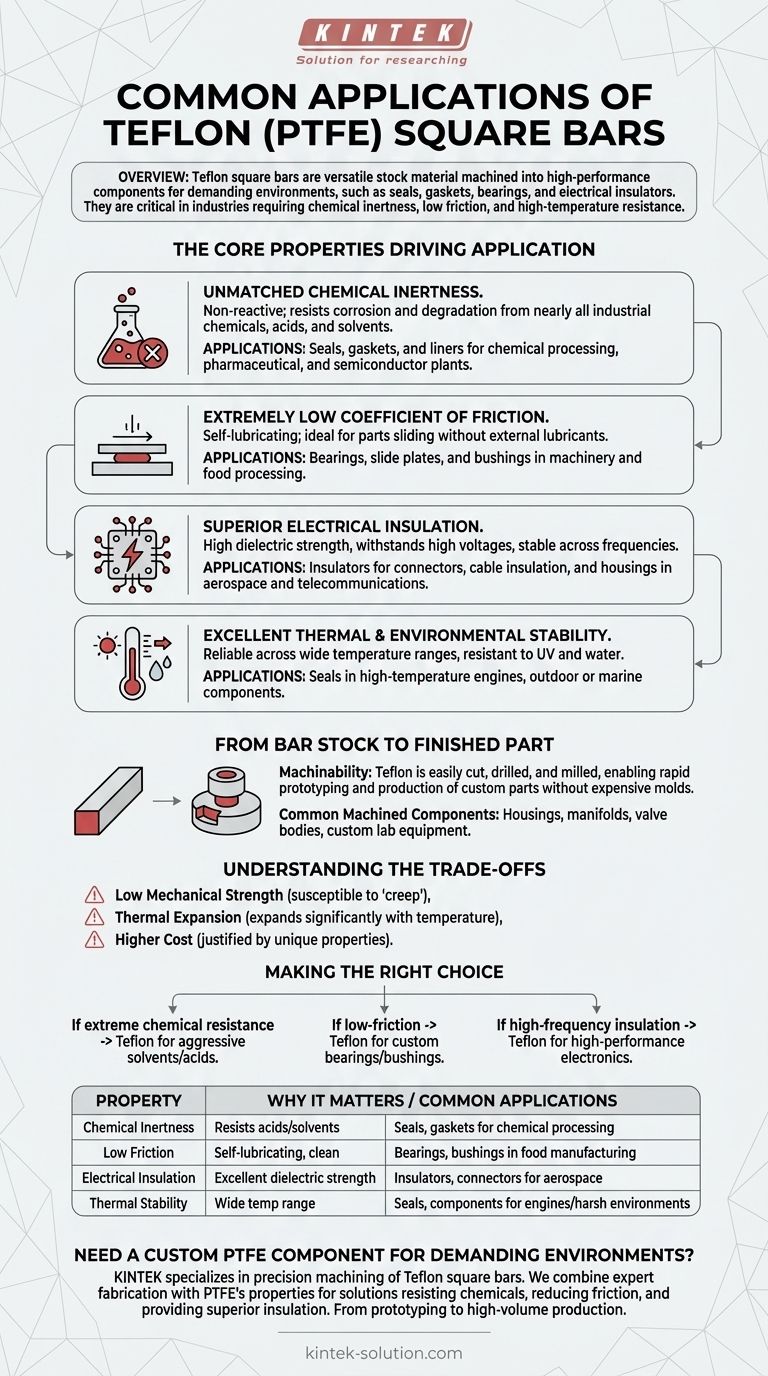

The Core Properties Driving Application

The value of Teflon square bars comes from a unique combination of material properties. Understanding these characteristics is key to seeing why it's chosen for such a diverse range of critical applications.

Unmatched Chemical Inertness

Teflon, or Polytetrafluoroethylene (PTFE), is famously non-reactive. It resists corrosion and degradation from nearly all industrial chemicals, acids, and solvents.

This property makes it the gold-standard material for parts used in aggressive chemical environments.

Common parts include seals, gaskets, and liners for pipes, valves, and storage tanks in chemical processing, pharmaceutical, and semiconductor manufacturing plants.

Extremely Low Coefficient of Friction

Teflon has one of the lowest friction coefficients of any solid material, often compared to wet ice on wet ice. This allows it to function as a self-lubricating surface.

This makes it ideal for creating parts that slide against each other without needing external lubricants.

Typical applications are bearings, slide plates, and bushings in machinery, especially in food processing where grease-based lubricants are prohibited. It's also the basis for its use in non-stick coatings.

Superior Electrical Insulation

Teflon is an excellent electrical insulator with a high dielectric strength, meaning it can withstand high voltages without breaking down. It also maintains these properties across a wide range of frequencies.

This characteristic is crucial for high-performance electronics and electrical systems.

It is frequently machined into insulators for connectors, cable insulation, and housings for sensitive electronic components, particularly in aerospace and telecommunications.

Excellent Thermal and Environmental Stability

Teflon performs reliably across a very wide temperature range and is resistant to degradation from UV radiation and water.

This durability ensures components maintain their integrity in harsh operating conditions, from cryogenic temperatures to high-heat environments.

This makes it suitable for seals in high-temperature engines and components used in outdoor or marine applications where weather resistance is essential.

From Bar Stock to Finished Part

The term "square bar" refers to the form factor of the raw material. Its true value is unlocked through machining, which transforms the stock bar into a precise, application-specific component.

The Importance of Machinability

Teflon is valued for its excellent machinability. It can be easily cut, drilled, and milled into complex shapes with tight tolerances using standard machine shop equipment.

This allows for the rapid prototyping and production of custom parts without the need for expensive molding processes.

Common Machined Components

The vast majority of Teflon applications stem from its use as a machined part.

Beyond the common seals and bearings, it is used for housings, manifolds, valve bodies, and custom lab equipment where its unique properties are required.

Understanding the Trade-offs

While incredibly useful, Teflon is not the right choice for every application. Being aware of its limitations is critical for successful engineering design.

Low Mechanical Strength

Teflon is a relatively soft material. It has low tensile strength and is susceptible to "creep," which is the tendency to slowly deform under a constant load.

Because of this, it is not suitable for structural components that must bear significant mechanical stress.

Thermal Expansion

Teflon has a higher coefficient of thermal expansion than metals. This means it expands and contracts significantly with temperature changes, a factor that must be accounted for in the design of close-fitting parts.

Higher Cost

As a high-performance polymer, Teflon is more expensive than common plastics like nylon or Delrin (acetal). Its use is typically justified only when its unique properties are a strict requirement for the application to succeed.

Making the Right Choice for Your Application

Selecting Teflon square bar for your project depends entirely on the problem you need to solve.

- If your primary focus is extreme chemical resistance: Teflon is the default choice for parts that will be exposed to aggressive solvents, acids, or bases.

- If your primary focus is creating a low-friction, self-lubricating surface: It is ideal for custom bearings, bushings, and slide plates, especially in clean environments.

- If your primary focus is high-frequency electrical insulation: Teflon's stable dielectric properties make it a top-tier material for high-performance electronic components.

Ultimately, Teflon square bar is the starting point for creating bespoke solutions to some of engineering's most demanding material challenges.

Summary Table:

| Property | Why It Matters | Common Applications |

|---|---|---|

| Chemical Inertness | Resists virtually all acids, solvents, and chemicals. | Seals, gaskets, liners for chemical processing. |

| Low Friction | Self-lubricating; ideal for clean environments. | Bearings, bushings, slide plates in food manufacturing. |

| Electrical Insulation | Excellent dielectric strength across frequencies. | Insulators, connectors, housings for aerospace electronics. |

| Thermal Stability | Performs from cryogenic to high temperatures. | Seals and components for engines and harsh environments. |

Need a custom PTFE component that can withstand your most demanding environment?

KINTEK specializes in precision machining of Teflon square bars into high-performance seals, liners, bearings, and labware for the semiconductor, medical, laboratory, and industrial sectors. We combine expert fabrication with the unique properties of PTFE to deliver solutions that resist chemicals, reduce friction, and provide superior insulation.

From rapid prototyping to high-volume production, we ensure your custom parts meet exact specifications. Contact KINTEK today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What additional construction applications exist for PTFE beyond slide bearings? Leverage PTFE for Thermal Breaks & Washers

- What are some common PTFE seal types used in industrial applications? Explore Solutions for Every Motion & Environment

- What are the limitations of PTFE in ball valve seat applications? Avoid Costly Seal Failures

- What are the benefits of using a PTFE coating thrust washer in a fishing reel? Smoother Drag, Longer Reel Life

- What are the characteristics of PTFE Lined Gate Valves? Ideal for Full-Bore Flow and Tight Shut-Off

- What are the disadvantages of Teflon washers? Key Limitations for Mechanical Design

- How does PTFE perform in chemical resistance applications? Unmatched Inertness for Harsh Environments

- What are the primary functions of PTFE expansion joints? Protect Piping Systems from Stress and Failure