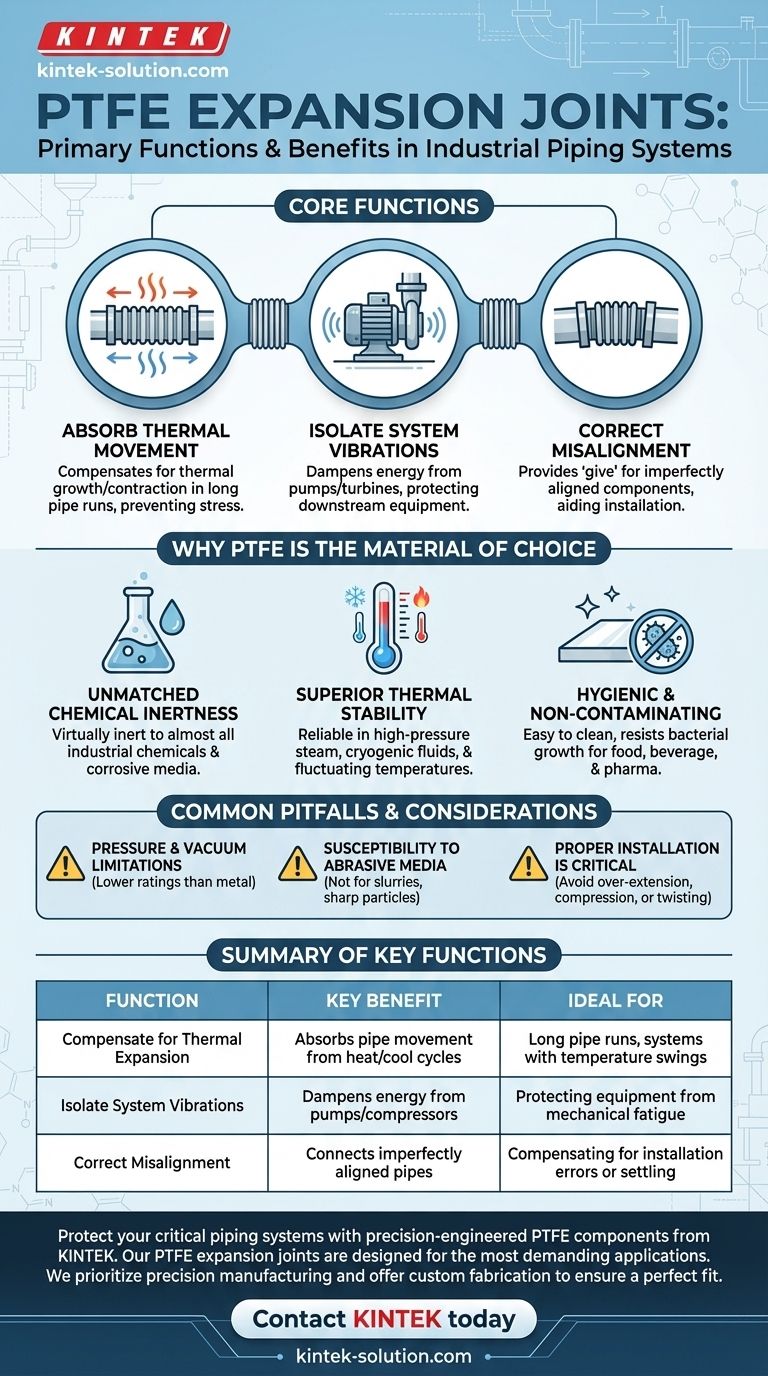

At their core, PTFE expansion joints perform three critical functions: they absorb pipe movement caused by thermal changes, isolate vibrations from equipment, and compensate for mechanical misalignment. These flexible connectors, also known as compensators or bellows, are engineered to prevent the self-destructive stresses that build up within rigid piping systems, ensuring operational integrity and safety.

An expansion joint is more than a simple connector; it is an engineered safety device. The unique properties of Polytetrafluoroethylene (PTFE) make it the definitive choice for protecting piping systems in chemically aggressive or high-purity environments where failure is not an option.

The Core Engineering Problems Solved

A rigid piping system is vulnerable to internal and external forces. PTFE expansion joints are designed specifically to neutralize these forces before they can cause catastrophic damage.

Compensating for Thermal Expansion and Contraction

All piping materials expand when heated and contract when cooled. In long pipe runs, this movement can generate immense stress, potentially leading to buckled pipes, damaged supports, or broken equipment flanges.

A PTFE expansion joint acts as a flexible bridge, compressing or extending to absorb this thermal growth without transferring the stress to the rest of the system.

Isolating System Vibrations

Equipment such as pumps, compressors, and turbines generate constant vibrations. When transmitted through a rigid piping system, this energy creates noise and mechanical fatigue, which can lead to premature failure at joints and connection points.

The flexibility of a PTFE bellow allows it to dampen and isolate these vibrations, effectively protecting downstream components and ensuring smoother, quieter operation.

Correcting Inevitable Misalignment

Achieving perfect, permanent alignment between two pieces of equipment or pipe sections is practically impossible. Initial installation errors, foundation settling, and operational wear can all create slight misalignments.

PTFE expansion joints provide the "give" needed to connect misaligned components, preventing the dangerous stresses that would occur if the pipes were forced into alignment.

Why PTFE is the Material of Choice

While expansion joints can be made from metal or rubber, PTFE offers a combination of properties that make it indispensable for demanding industrial applications.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and corrosive media. This makes it the ideal material for use in chemical processing, petrochemical, and pharmaceutical plants where aggressive substances would quickly degrade other materials.

Superior Thermal Stability

PTFE maintains its properties across a wide range of temperatures. This allows it to function reliably in systems handling high-pressure steam, cryogenic fluids, or fluctuating process temperatures found in power plants and manufacturing facilities.

Hygienic and Non-Contaminating Properties

The non-stick, non-porous surface of PTFE is easy to clean and resists bacterial growth. This is a critical requirement in food, beverage, and pharmaceutical industries, where maintaining product purity is paramount.

Common Pitfalls and Considerations

While highly effective, PTFE expansion joints are not a universal solution. Understanding their limitations is key to successful implementation.

Pressure and Vacuum Limitations

Compared to robust metallic bellows, standard PTFE joints have lower pressure and vacuum ratings. For extremely high-pressure systems, a specialized or metal expansion joint may be required.

Susceptibility to Abrasive Media

PTFE is a relatively soft material. It is not well-suited for applications involving abrasive slurries, as sharp particles can erode the liner and lead to premature failure.

Proper Installation is Critical

The effectiveness of an expansion joint depends entirely on correct installation. Over-extending, over-compressing, or twisting the joint during installation will compromise its integrity and negate its benefits.

Making the Right Choice for Your Application

Selecting the correct component requires matching its strengths to your system's primary challenge.

- If your primary focus is handling aggressive chemicals: PTFE's near-total chemical inertness makes it the safest and most reliable choice to prevent leaks and corrosion.

- If your primary focus is high-purity or sanitary systems: Its non-contaminating and hygienic properties are essential for meeting stringent standards in pharmaceutical or food processing.

- If your primary focus is protecting equipment from thermal stress and vibration: A PTFE expansion joint is the most effective way to decouple pumps and vessels from rigid pipe runs.

Ultimately, understanding these core functions is a foundational step in designing and maintaining a resilient, safe, and long-lasting industrial piping system.

Summary Table:

| Function | Key Benefit | Ideal For |

|---|---|---|

| Compensate for Thermal Expansion | Absorbs pipe movement from heat/cool cycles | Long pipe runs, systems with temperature swings |

| Isolate System Vibrations | Dampens energy from pumps/compressors | Protecting equipment from mechanical fatigue |

| Correct Misalignment | Connects imperfectly aligned pipes | Compensating for installation errors or settling |

Protect your critical piping systems with precision-engineered PTFE components from KINTEK.

Our PTFE expansion joints are designed for the most demanding applications in semiconductor, medical, laboratory, and industrial settings. We prioritize precision manufacturing and offer custom fabrication—from prototypes to high-volume orders—to ensure a perfect fit and reliable performance for your specific needs.

Contact KINTEK today to discuss your project requirements and discover how our expertise can enhance your system's safety and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments