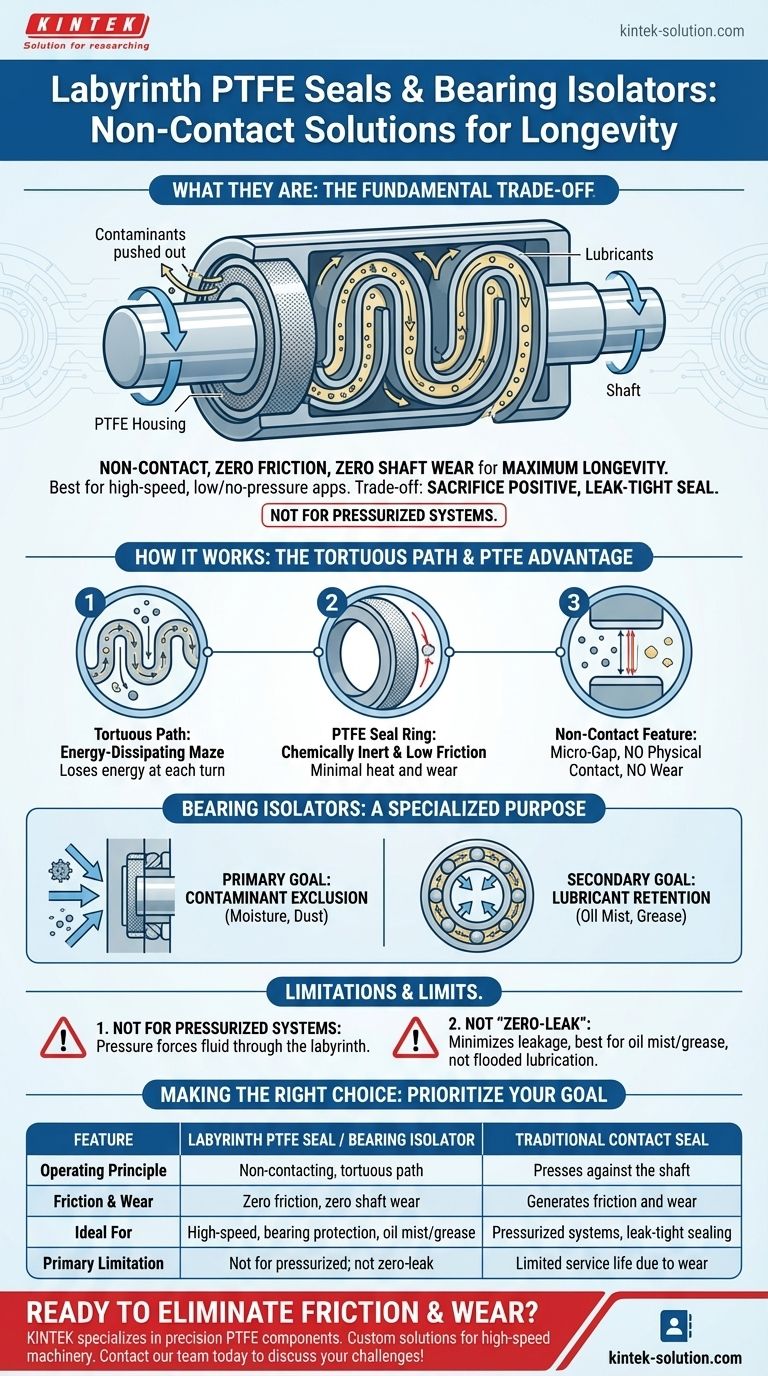

At their core, Labyrinth PTFE Seals and Bearing Isolators are non-contacting seals designed for rotating equipment in low or no-pressure environments. Unlike traditional seals that press against a shaft to stop leaks, they feature a PTFE (Teflon) ring set within a grooved housing, creating a complex, winding path that makes it extremely difficult for contaminants to get in or lubricants to get out.

The fundamental trade-off is this: you sacrifice a perfectly leak-tight, positive seal in exchange for zero friction, zero shaft wear, and a dramatically longer service life, making them ideal for high-speed applications where reliability is paramount.

How a Labyrinth Seal Actually Works

The term "labyrinth" is not just a name; it's a direct description of the sealing strategy. It forces fluid or contaminants to navigate a difficult, energy-dissipating maze.

The Principle of the Tortuous Path

A labyrinth seal creates a series of tight clearances and directional changes. As lubricant tries to escape or external contaminants try to enter, they must pass through this maze.

Each turn in the path forces the fluid or particle to lose energy, effectively preventing it from completing its journey. This is a dynamic, non-contact method of containment.

The Critical Role of PTFE

The seal ring itself is made from PTFE for two key reasons. First, its extremely low coefficient of friction ensures that if any incidental contact does occur, it generates minimal heat and wear.

Second, PTFE is chemically inert, making it suitable for a vast range of industrial lubricants and process fluids without degrading.

Why "Non-Contact" is the Key Feature

The seal operates with a micro-gap between the rotating shaft and the stationary seal. This complete separation is the source of its primary benefits.

Because there is no physical contact during operation, there is no friction to generate heat, no seal lip to wear out, and absolutely no wear on the shaft itself.

Bearing Isolators: A Specialized Application

While "labyrinth seal" is the general term for the technology, a "bearing isolator" is a specific type of labyrinth seal with a focused purpose.

Primary Goal: Contaminant Exclusion

The main job of a bearing isolator is to protect the bearing. It creates a powerful barrier against the primary causes of bearing failure: moisture, dust, and other external contaminants.

Secondary Goal: Lubricant Retention

While keeping contaminants out, the isolator's internal labyrinth path also captures and redirects oil mist or grease back toward the bearing, ensuring it remains properly lubricated.

Understanding the Trade-offs and Limitations

This sealing technology is a superior solution for specific problems, but it is not a universal replacement for all seal types. Understanding its limitations is crucial for proper application.

Limitation 1: Not for Pressurized Systems

The non-contact design means there is a clear path for fluid to travel. If the system is pressurized, that pressure will simply force the fluid through the labyrinth.

These seals are only effective in low-pressure or ambient (non-pressurized) conditions.

Limitation 2: Not a "Zero-Leak" Solution

In applications with oil splash or flooded lubrication, a labyrinth seal is designed to manage and minimize leakage, not eliminate it entirely like a positive contact seal. It is best suited for applications with oil mist or grease lubrication.

Making the Right Choice for Your Goal

Deciding between a labyrinth seal and a traditional contact seal comes down to the primary goal of your application.

- If your primary focus is longevity and high-speed performance: A labyrinth seal or bearing isolator is the superior choice, as it eliminates wear and friction on the shaft.

- If your primary focus is protecting bearings in pumps, motors, or gearboxes: A bearing isolator is the specific and correct product for the job.

- If your primary focus is creating a leak-proof seal in a pressurized system: This is the wrong technology; you must use a positive contact seal, such as a mechanical or lip seal.

By prioritizing the operational demands of your equipment, you can select the sealing technology that delivers the most effective and reliable performance.

Summary Table:

| Feature | Labyrinth PTFE Seal / Bearing Isolator | Traditional Contact Seal |

|---|---|---|

| Operating Principle | Non-contacting, tortuous path | Presses against the shaft |

| Friction & Wear | Zero friction, zero shaft wear | Generates friction and wear |

| Ideal For | High-speed, bearing protection, oil mist/grease | Pressurized systems, leak-tight sealing |

| Primary Limitation | Not for pressurized systems; not zero-leak | Limited service life due to wear |

Ready to eliminate friction and wear in your equipment?

KINTEK specializes in precision-engineered PTFE components, including labyrinth seals and bearing isolators. We can help you achieve unparalleled reliability and longevity for your high-speed machinery in the semiconductor, medical, laboratory, and industrial sectors.

Our experts provide custom fabrication from prototypes to high-volume orders. Contact our team today to discuss your specific sealing challenges and find the perfect solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What aerospace applications utilize PTFE seals? Ensure Reliability in Extreme Conditions

- What temperature range can PTFE balls withstand, and why is this beneficial? Unlock Extreme Thermal Performance

- How are PTFE rods used in the chemical industry? Ensure Safety and Reliability in Corrosive Environments

- What are the characteristics of graphite filled PTFE? Enhance Wear Resistance & Self-Lubrication

- What are the primary applications of PTFE PCBs? The Ultimate Guide for High-Frequency & Harsh Environments

- How does the manufacturing of PTFE expansion joints accommodate industry-specific needs? Tailor-Made Solutions for Your Application

- How does the lifecycle cost of Teflon gland packing compare to traditional materials? Achieve Lower Total Cost of Ownership

- How is PTFE applied in the medical field? Enhancing Patient Care with Biocompatible Solutions