In short, manufacturers tailor PTFE expansion joints by selecting specific raw material production methods and employing a range of precision fabrication techniques. This dual approach ensures the final product not only fits physically but also meets the stringent chemical resistance, purity, and compliance standards of a specific industry, from wastewater treatment to food processing.

The customization of a PTFE expansion joint is not a single action but a multi-stage process. It begins with the fundamental choice of how the raw PTFE is created and culminates in precision shaping to meet the exact operational and environmental demands of its intended application.

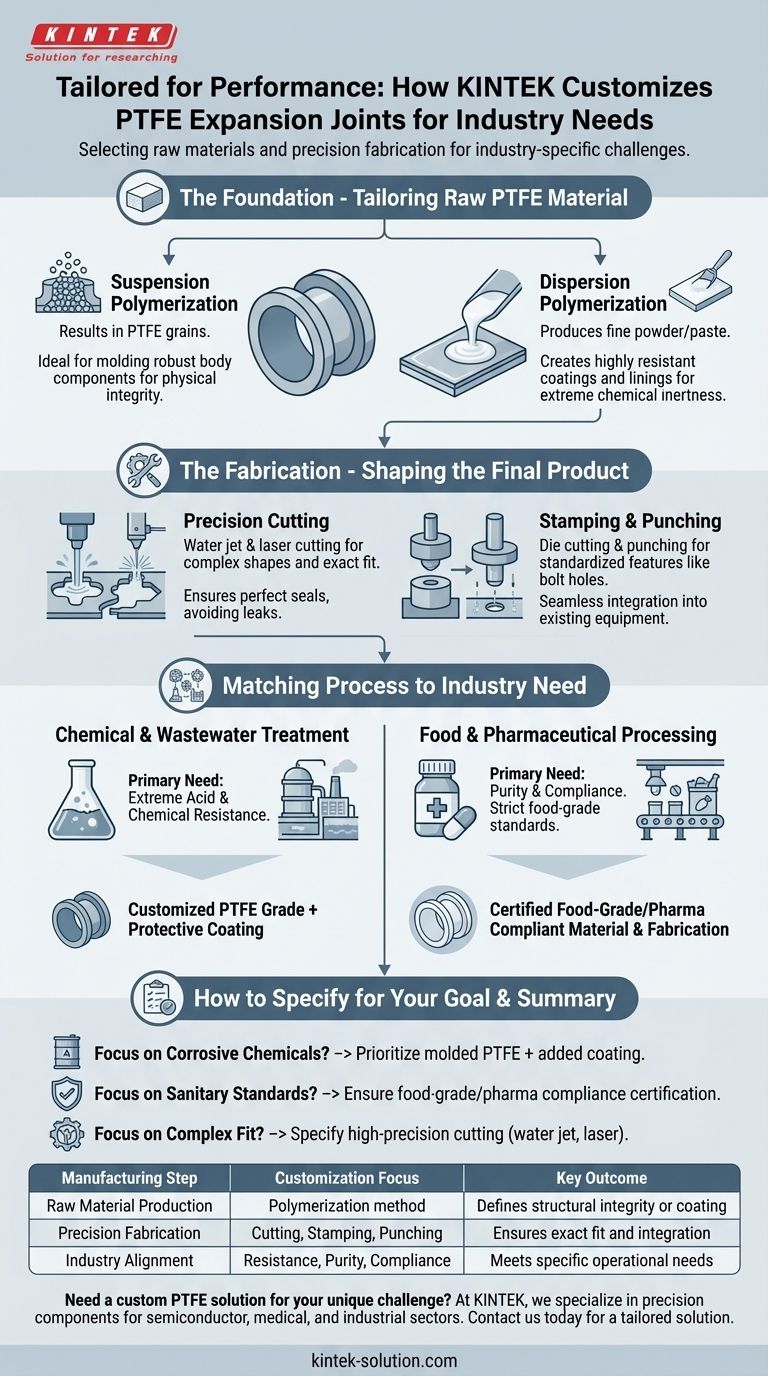

The Foundation: Tailoring Raw PTFE Material

Before an expansion joint can be shaped, the base PTFE material itself must be produced in a form suitable for the end-use. The chosen polymerization method is the first and most critical step in customization.

Suspension Polymerization for Molded Structures

This process results in PTFE grains. These solid particles are ideal for being molded under heat and pressure to form the main, robust body of an expansion joint.

This method is the foundation for creating the core structural components that require significant physical integrity and a defined shape.

Dispersion Polymerization for Specialized Coatings

This technique produces a fine powder or a milky paste. This form of PTFE is not typically molded on its own but is used to create highly resistant coatings and linings.

For industries requiring extreme chemical inertness, this paste can be applied to joint surfaces, providing an enhanced barrier against corrosive materials.

The Fabrication: Shaping the Final Product

Once the appropriate form of PTFE is selected, manufacturers use a variety of precision techniques to shape the material into the final expansion joint, meeting exact dimensional specifications.

Precision Cutting for Exact Dimensions

Techniques like water jet cutting and laser cutting are employed to create complex shapes and ensure the joint fits perfectly within a specific piping system.

These methods offer high precision, which is critical for achieving a perfect seal and avoiding leaks in sensitive applications.

Stamping and Punching for Integration

Die cutting, stamping, and punching are used to create standardized features like bolt holes and flange patterns.

This ensures the custom-made joint can be seamlessly integrated into existing industrial equipment without modifications.

Matching the Process to the Industry Need

The true art of customization lies in aligning these manufacturing capabilities with the specific challenges and regulatory requirements of a given industry.

For Chemical and Wastewater Treatment

The primary need here is extreme acid and chemical resistance. Customization focuses on using PTFE grades produced for maximum inertness, often enhanced with coatings derived from dispersion polymerization.

The goal is to ensure long-term durability and prevent environmental contamination by containing corrosive substances effectively.

For Food and Pharmaceutical Processing

In these industries, purity and compliance are non-negotiable. Manufacturing must adhere to strict food-grade standards.

The customization process ensures no contaminants are introduced, and the final product is both non-toxic and non-reactive with the materials it will contact.

How to Specify for Your Goal

The right customization path depends entirely on your primary operational driver.

- If your primary focus is containing highly corrosive chemicals: Prioritize a joint made from a suitable molded PTFE grade, potentially with an added coating for enhanced protection.

- If your primary focus is meeting sanitary standards: Ensure your supplier certifies that both the raw PTFE material and all fabrication processes comply with food-grade or pharmaceutical regulations.

- If your primary focus is fitting into a complex or non-standard system: Specify the need for high-precision fabrication methods like water jet or laser cutting to guarantee exact dimensional accuracy.

Ultimately, understanding these manufacturing levers empowers you to specify a component that is not just a part, but a purpose-built solution for your unique challenge.

Summary Table:

| Manufacturing Step | Customization Focus | Key Outcome |

|---|---|---|

| Raw Material Production | Polymerization method (Suspension/Dispersion) | Defines structural integrity or coating capability |

| Precision Fabrication | Cutting (Water jet, Laser), Stamping, Punching | Ensures exact fit and seamless integration |

| Industry Alignment | Chemical resistance, Purity standards, Compliance | Meets specific operational and regulatory needs |

Need a PTFE expansion joint built for your specific challenge?

At KINTEK, we specialize in manufacturing custom PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our process begins with your unique requirements—whether it's extreme chemical resistance for wastewater treatment or certified purity for pharmaceutical processing. We leverage precision production and custom fabrication, from prototypes to high-volume orders, to deliver a solution that ensures performance, compliance, and durability.

Contact us today to discuss your project and receive a tailored solution that fits your system and exceeds your standards.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability