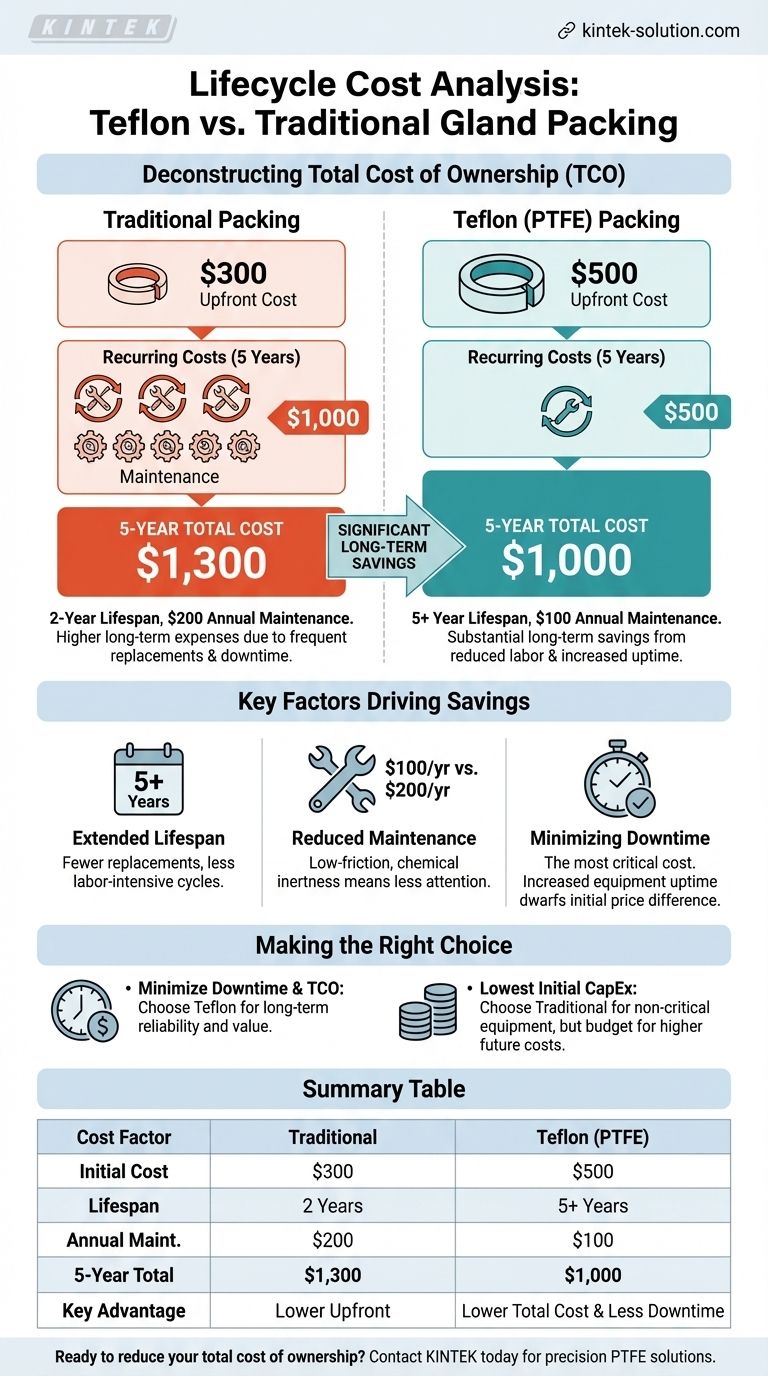

At first glance, Teflon packing is more expensive, but when analyzing the total cost over the equipment's lifecycle, it is significantly more economical than traditional packing materials. While a traditional packing set might cost $300 upfront versus $500 for Teflon, the traditional option's shorter lifespan and higher maintenance needs lead to a total cost of $1300 over five years, compared to just $1000 for Teflon in the same period.

The core insight is that the higher initial investment in Teflon (PTFE) gland packing is consistently offset by substantial long-term savings. These savings are realized through a longer service life, reduced maintenance labor, and most critically, a dramatic reduction in costly equipment downtime.

Deconstructing the Total Cost of Ownership

Many procurement decisions are skewed by focusing on the initial purchase price. To make a sound technical and financial choice, you must evaluate the Total Cost of Ownership (TCO), which reveals the true cost of a component over its entire service life.

The Upfront Cost Illusion

Traditional packing materials often have a lower sticker price, making them appear to be the more budget-friendly option. For example, a set might cost $300, while a comparable Teflon packing set costs $500.

This initial saving is appealing, but it represents only a fraction of the total cost and ignores the recurring expenses that accumulate over time.

Calculating the True Annual Cost

The financial advantage of Teflon becomes clear when you factor in its lifespan and maintenance needs.

Using a 5-year operational window as a baseline, Teflon packing, with a 5-year lifespan and $100 annual maintenance, has a true annual cost of $200.

In contrast, traditional packing, with a 2-year lifespan and $200 annual maintenance, requires replacement. Its true annual cost is closer to $350, factoring in the repeated material and labor costs for replacement.

Key Factors Driving Long-Term Savings

The lower lifecycle cost of Teflon packing is not based on a single factor, but on a combination of performance characteristics that reduce direct and indirect expenses.

Extended Lifespan and Replacement Frequency

The most significant factor is service life. Teflon packing can last 5 years or more in the right application, compared to the typical 2-year lifespan of many traditional materials.

This longevity directly translates to fewer purchases and, just as importantly, fewer labor-intensive replacement cycles over the life of the equipment.

Reduced Maintenance Requirements

Teflon's low-friction surface and chemical inertness mean it requires fewer adjustments and less attention from maintenance staff.

Lower annual maintenance costs ($100 vs. $200 in our example) reflect less time spent tightening glands and managing leaks, freeing up personnel for more critical tasks.

The Critical Impact of Downtime

This is the most crucial, yet often overlooked, cost. Every time a pump or valve must be shut down to replace packing, the entire process it supports comes to a halt.

Because Teflon packing is replaced far less frequently, it drastically increases equipment uptime. The cost of this avoided production loss often dwarfs the initial price difference between the packing materials.

Understanding the Trade-offs

While the data points toward Teflon, an objective analysis requires acknowledging its limitations and the contexts where other options might be suitable.

When Traditional Packing Might Suffice

For non-critical equipment that is used intermittently or operates under very low-pressure and low-temperature conditions, the higher cost of Teflon may not be justifiable. If the financial impact of downtime for that specific piece of equipment is negligible, the lower initial cost of traditional packing can be a reasonable choice.

The Importance of Proper Installation

The high-performance benefits of Teflon packing are contingent upon correct installation. The material is less forgiving of shaft imperfections or improper handling during installation compared to some traditional fiber packings. An incorrectly installed Teflon ring can fail prematurely, negating its potential cost savings.

Making the Right Choice for Your Application

Your final decision should be guided by your primary operational and financial goals.

- If your primary focus is minimizing downtime and total long-term cost: Teflon packing is the superior financial and operational choice due to its extended lifespan and reliability.

- If your primary focus is the lowest possible initial capital expenditure: Traditional packing provides a lower upfront cost, but you must budget for higher maintenance labor and more frequent shutdowns.

- If you are managing non-critical or backup equipment: The cost-benefit analysis may favor traditional packing if the associated downtime for replacement does not impact production.

Ultimately, choosing the right packing material is an exercise in shifting focus from the initial price tag to the total value delivered over time.

Summary Table:

| Cost Factor | Traditional Packing | Teflon (PTFE) Packing |

|---|---|---|

| Initial Material Cost | $300 | $500 |

| Typical Lifespan | 2 Years | 5+ Years |

| Annual Maintenance Cost | $200 | $100 |

| 5-Year Total Cost | $1,300 | $1,000 |

| Key Advantage | Lower upfront cost | Lower total cost & less downtime |

Ready to reduce your total cost of ownership and minimize costly downtime?

KINTEK specializes in manufacturing high-performance, precision PTFE components like gland packing, seals, and liners. Our custom fabrication services—from prototypes to high-volume orders—ensure you get the exact solution for your application in the semiconductor, medical, laboratory, and industrial sectors.

Contact us today to discuss how our PTFE solutions can enhance your equipment's reliability and profitability.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications