In essence, graphite-filled PTFE is a composite material designed to enhance the performance of standard Polytetrafluoroethylene (PTFE). By blending 5% to 15% graphite particles into the PTFE base, the resulting material gains significantly improved wear resistance, strength, and stability under load. This modification retains PTFE's excellent chemical resistance while adding superior self-lubricating properties, making it a high-performance solution for demanding mechanical applications.

The core purpose of adding graphite to PTFE is to transform it from a soft, low-friction liner into a durable, self-lubricating engineering component. It addresses the inherent weakness of pure PTFE—its tendency to deform and wear under mechanical stress—without sacrificing its key chemical and thermal advantages.

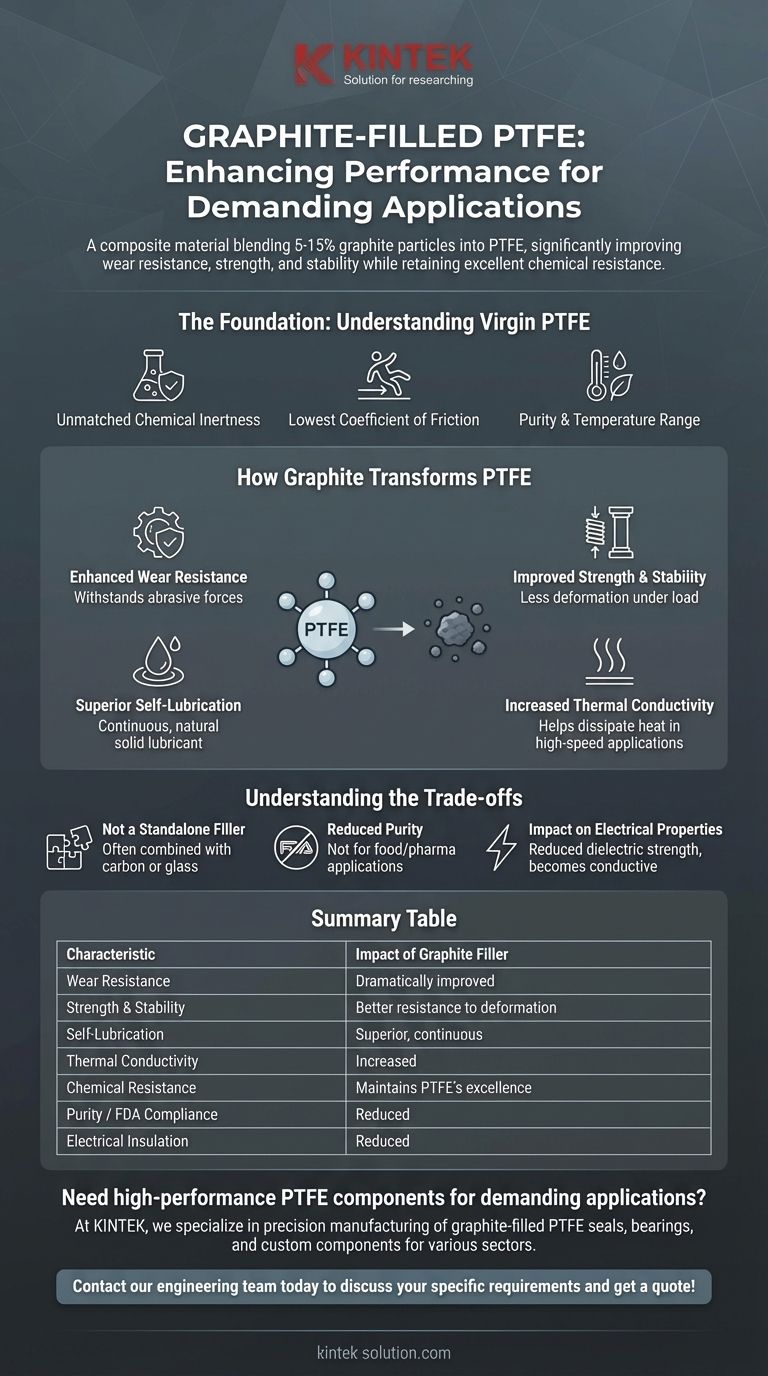

The Foundation: Understanding Virgin PTFE

To appreciate the role of graphite, we must first understand the remarkable properties of the base material. Virgin PTFE is an exceptional polymer known for several key characteristics that make it useful in its own right.

Unmatched Chemical Inertness

Pure PTFE is virtually impervious to chemical attack. It has tremendous resistance to a wide range of chemicals, including the most aggressive acids, making it a default choice for seals and linings in corrosive environments.

The Lowest Coefficient of Friction

PTFE possesses one of the lowest coefficients of friction of any known solid material. This inherent slipperiness is what makes it famous for non-stick coatings and low-friction applications.

Purity and Temperature Range

The material is naturally clean, non-toxic, and can meet FDA standards, which is critical for food and pharmaceutical industries. It also performs well across a wide range of temperatures.

How Graphite Transforms PTFE

While virgin PTFE is chemically robust, it is also mechanically soft and prone to "creep" or deform under pressure. Adding graphite directly addresses these mechanical limitations.

Enhanced Wear Resistance

The primary benefit of graphite is a dramatic improvement in wear properties. The graphite particles provide a structural reinforcement that helps the material withstand abrasive forces far better than pure PTFE.

Improved Strength and Stability

Graphite-filled PTFE exhibits much better deformation under load. This means it is less likely to compress or change shape when subjected to pressure, making it ideal for components like gaskets and bearings that must maintain their form to function.

Superior Self-Lubrication

Graphite is a natural solid lubricant. Its integration into the PTFE matrix creates a material that is continuously self-lubricating, which is critical for high-speed dynamic applications where external lubrication is impossible or undesirable.

Increased Thermal Conductivity

A key, often overlooked benefit is improved thermal conductivity. Virgin PTFE is a thermal insulator, meaning it traps heat. In high-speed applications like rotating shafts, this heat buildup can lead to failure. Graphite helps dissipate this heat away from the sealing surface, extending the component's life and operational speed.

Understanding the Trade-offs

Adding graphite is a targeted engineering choice, and it comes with considerations that may make it unsuitable for certain applications.

Not a Standalone Filler

Graphite is very effective, but it is often combined with other fillers like carbon or glass to achieve an even more robust set of properties. The specific blend is crucial for the end application.

Reduced Purity

While virgin PTFE is known for its purity and FDA compliance, the addition of industrial graphite means the resulting composite is typically not suitable for food, beverage, or pharmaceutical applications where such standards are required.

Impact on Electrical Properties

Pure PTFE is an excellent electrical insulator. Graphite, however, is electrically conductive. Adding it to the mix will significantly reduce the material's dielectric strength, making it unsuitable for applications requiring high electrical insulation.

Making the Right Choice for Your Application

Selecting the correct PTFE formulation depends entirely on the mechanical, chemical, and environmental demands of your project.

- If your primary focus is high-speed dynamic seals or bearings: The self-lubrication and thermal conductivity of graphite-filled PTFE make it a far superior choice over virgin PTFE.

- If your primary focus is chemical resistance in a static environment: Virgin PTFE is often sufficient and more cost-effective, as the enhanced wear properties are not required.

- If your primary focus is FDA compliance or electrical insulation: You must use virgin PTFE or a specifically certified compound, as standard graphite filler compromises these core properties.

By understanding these key characteristics, you can select the precise PTFE formulation that meets your engineering demands.

Summary Table:

| Characteristic | Impact of Graphite Filler |

|---|---|

| Wear Resistance | Dramatically improved, withstands abrasive forces |

| Strength & Stability | Better resistance to deformation under load |

| Self-Lubrication | Superior, continuous lubrication for dynamic parts |

| Thermal Conductivity | Increased, helps dissipate heat in high-speed applications |

| Chemical Resistance | Maintains PTFE's excellent chemical inertness |

| Purity / FDA Compliance | Reduced, not suitable for food/pharma applications |

| Electrical Insulation | Reduced, graphite makes the material conductive |

Need high-performance PTFE components for demanding applications?

At KINTEK, we specialize in precision manufacturing of graphite-filled PTFE seals, bearings, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get durable, self-lubricating parts that enhance performance and longevity in your most critical applications.

Contact our engineering team today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance