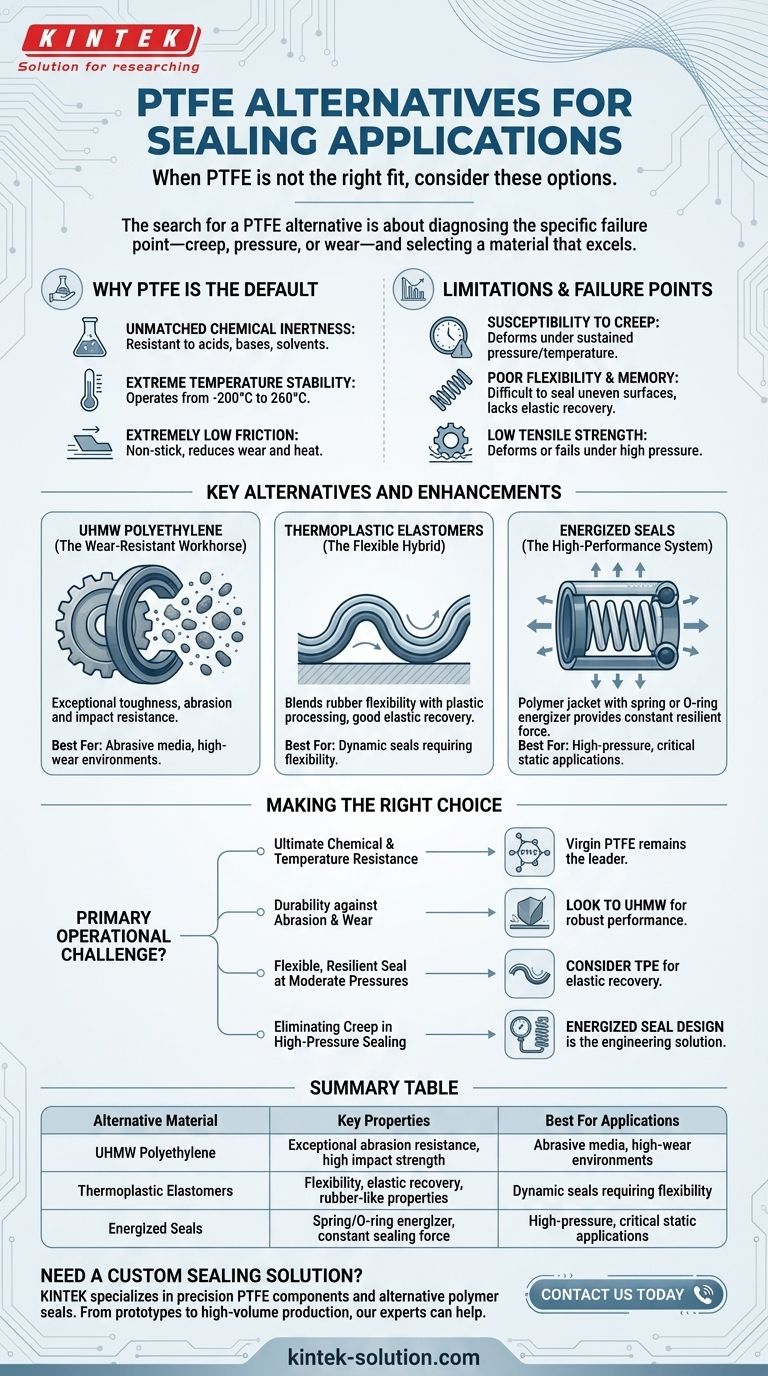

When PTFE is not the right fit, the primary material alternatives for demanding sealing applications are Ultra-High Molecular Weight Polyethylene (UHMW) and thermoplastic elastomers. These non-PTFE polymers offer different mechanical properties, while system-level enhancements like spring or O-ring energizers can be used to augment the performance of various plastics for ultra-tight sealing.

The search for a PTFE alternative is not about finding a superior material, but about diagnosing the specific failure point of PTFE in your application—be it creep, pressure, or wear—and selecting a material that excels in that specific dimension.

First, Understand Why PTFE Is the Default Choice

Before exploring alternatives, it's critical to understand why Polytetrafluoroethylene (PTFE) is a benchmark for high-performance seals. Its unique molecular structure makes it the default choice in many industries.

Unmatched Chemical Inertness

The strong carbon-fluorine bonds in PTFE's structure make it resistant to nearly all acids, bases, and organic solvents. This allows it to operate in extremely corrosive environments where other materials would quickly degrade.

Extreme Temperature Stability

PTFE maintains its integrity and sealing properties across an exceptionally wide temperature range, typically from -200°C to 260°C (-328°F to 500°F). It can handle conditions that are too extreme for standard elastomers but do not warrant the use of metal seals.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This non-stick characteristic is invaluable in dynamic sealing applications, as it reduces wear, energy consumption, and heat generation.

The Limitations of PTFE: When to Look for an Alternative

Despite its strengths, PTFE is not universally applicable. Its weaknesses become apparent under specific mechanical stresses, prompting the need for alternatives.

Susceptibility to Creep

Under sustained pressure and temperature, pure PTFE is prone to creep, or cold flow. This means the material slowly deforms over time, which can lead to a loss of sealing force and eventual leakage.

Poor Flexibility and Memory

Pure, unfilled PTFE is a relatively rigid material. This can make it difficult to achieve a consistent, tight seal, especially on uneven surfaces, as it lacks the "memory" or elastic recovery of rubber-like materials.

Low Tensile Strength

PTFE is not suitable for very high-pressure applications on its own. Its low tensile strength means it can deform, extrude, or fail entirely when subjected to high mechanical loads.

Key Alternatives and Enhancements

When PTFE's mechanical limitations are a concern, other materials or system designs provide a solution.

UHMW Polyethylene (The Wear-Resistant Workhorse)

Ultra-High Molecular Weight Polyethylene (UHMW) is a thermoplastic known for its exceptional toughness and outstanding resistance to abrasion and impact. It often outperforms PTFE in applications involving abrasive media or high wear.

Thermoplastic Elastomers (The Flexible Hybrid)

Thermoplastic elastomers (TPEs) blend the flexibility and sealing capability of rubber with the processing advantages of plastic. They are an excellent choice when you need better elastic recovery and flexibility than PTFE can provide, particularly in lower-pressure dynamic seals.

Energized Seals (The High-Performance System)

An energized seal is a system, not just a material. It involves a high-performance polymer jacket (which can be PTFE, UHMW, or another polymer) and a spring or O-ring energizer. The energizer provides a constant, resilient force against the sealing surfaces, overcoming PTFE's tendency to creep and providing a durable, tight seal in high-pressure and critical static applications.

Making the Right Choice for Your Goal

Selecting the correct sealing solution requires aligning the material's properties with your primary operational challenge.

- If your primary focus is ultimate chemical and temperature resistance: Virgin PTFE remains the undisputed leader for service in extreme chemical and thermal environments.

- If your primary focus is durability against abrasion and wear: Look to UHMW as a more robust alternative for applications with abrasive slurries or high-cycle dynamic motion.

- If your primary focus is a flexible, resilient seal at moderate pressures: A thermoplastic elastomer may provide the necessary elastic recovery that pure PTFE lacks.

- If your primary focus is eliminating creep in high-pressure static or dynamic sealing: An energized seal design is the most effective engineering solution.

Ultimately, the best sealing solution comes from precisely matching the material's strengths to the application's demands.

Summary Table:

| Alternative Material | Key Properties | Best For Applications |

|---|---|---|

| UHMW Polyethylene | Exceptional abrasion resistance, high impact strength | Abrasive media, high-wear environments |

| Thermoplastic Elastomers | Flexibility, elastic recovery, rubber-like properties | Dynamic seals requiring flexibility |

| Energized Seals | Spring/O-ring energizer, constant sealing force | High-pressure, critical static applications |

Need a custom sealing solution? KINTEK specializes in manufacturing precision PTFE components and alternative polymer seals for semiconductor, medical, laboratory, and industrial applications. Our experts can help you select or fabricate the perfect sealing solution—from prototypes to high-volume production. Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key properties of PTFE that make it suitable for seals? Unlock Reliability in Extreme Conditions

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance

- What are some common PTFE seal types used in industrial applications? Explore Solutions for Every Motion & Environment

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance