From aerospace to food processing, Polytetrafluoroethylene (PTFE) gaskets are prized for their exceptional performance under demanding conditions. Their primary advantages are unmatched chemical resistance, a vast operating temperature range, and an inherently non-stick surface, making them one of the most versatile sealing materials available.

The core strength of PTFE comes from its unique molecular structure: incredibly strong carbon-fluorine bonds that render it nearly immune to chemical attack. While this provides elite performance, the key to successful application is understanding its mechanical limitations—specifically cold flow—and selecting the right type of PTFE to mitigate them.

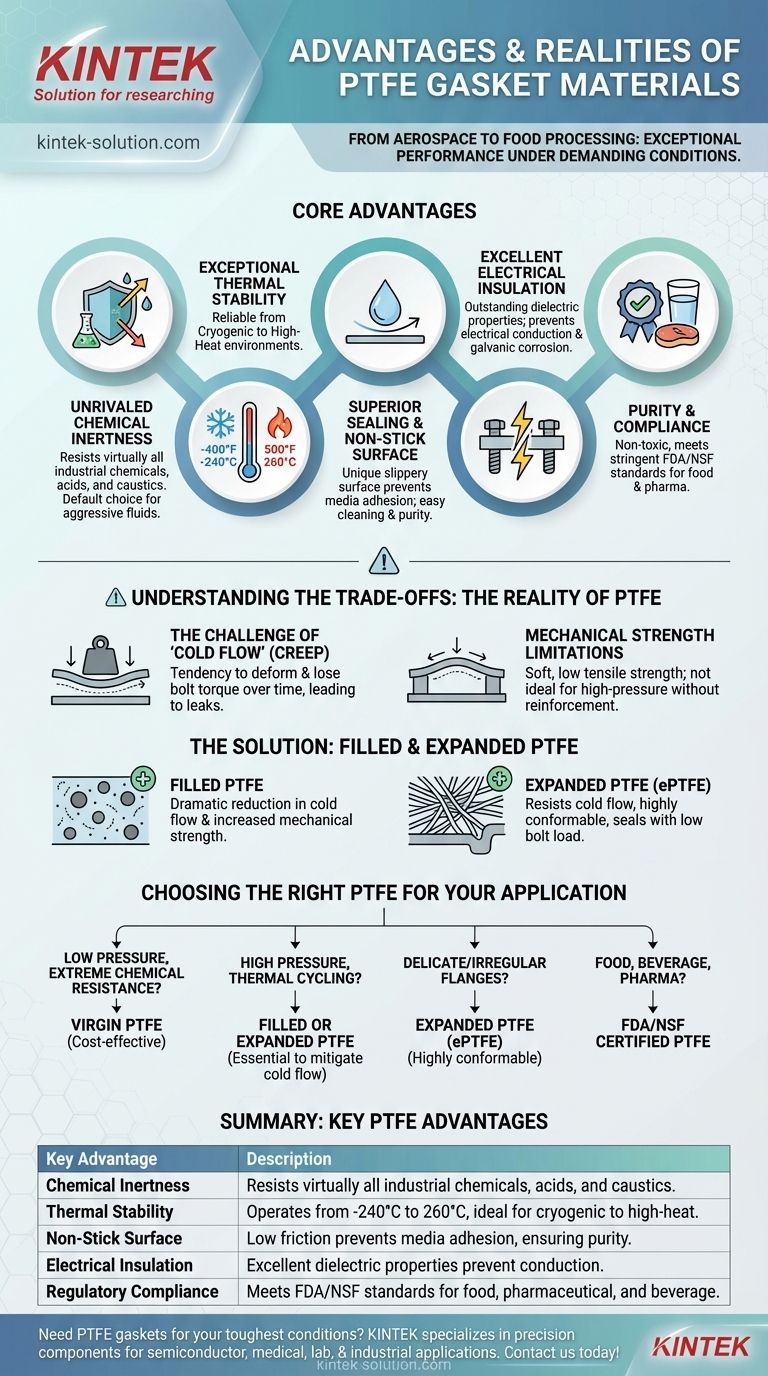

The Core Advantages Explained

The benefits of PTFE are not just a list of features; they are interconnected properties that stem directly from its chemical makeup. Understanding these connections is key to leveraging the material effectively.

Unrivaled Chemical Inertness

PTFE is one of the most chemically resistant materials known. It is virtually inert and will not react with or degrade when exposed to the vast majority of industrial chemicals, acids, and caustics.

This makes it the default choice for sealing systems that handle aggressive fluids, protecting the integrity of the process and preventing gasket failure.

Exceptional Thermal Stability

PTFE gaskets perform reliably across an extremely wide temperature range, typically from cryogenic lows of -400°F (-240°C) up to continuous service temperatures of 500°F (260°C).

This stability allows it to be used in applications that experience significant temperature swings or operate at sustained extremes, from liquified gas processing to high-temperature chemical reactors.

Superior Sealing and Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material, giving it a uniquely slippery, non-stick surface.

This property prevents process media from adhering to the gasket, simplifying cleaning and ensuring product purity. It also allows for easy removal of the gasket during maintenance without leaving residue on the flange faces.

Excellent Electrical Insulation

PTFE possesses outstanding dielectric properties, meaning it does not conduct electricity. This makes it an excellent insulator.

This characteristic is critical for applications where the gasket must prevent electrical current from passing between two connected flange components, ensuring electrical safety and preventing galvanic corrosion.

Purity and Compliance

Virgin PTFE is inherently non-toxic and can be manufactured to meet stringent regulatory standards.

Because of its purity and inertness, PTFE is widely approved for use in food, beverage, and pharmaceutical applications, complying with standards set by the FDA and NSF.

Understanding the Trade-offs: The Reality of PTFE

While its advantages are significant, no material is perfect. A clear-eyed understanding of PTFE's limitations is crucial for proper specification and avoiding seal failure.

The Challenge of "Cold Flow" (Creep)

The most significant limitation of standard, or "virgin," PTFE is cold flow, also known as creep. This is the tendency of the material to slowly deform and "flow" away from the point of compressive load over time.

This can lead to a loss of bolt torque on the flange, reducing the sealing pressure and potentially causing a leak, especially in applications with pressure or temperature cycling.

Mechanical Strength Limitations

Pure PTFE is a relatively soft material with low tensile strength compared to other gasket options. It can be easily damaged by over-tightening flanges or by abrasive conditions.

This softness means it is not always suitable for extremely high-pressure applications without some form of reinforcement.

The Solution: Filled and Expanded PTFE

Engineers have overcome these limitations by modifying PTFE. Filled PTFE incorporates materials like glass, silica, or carbon into the matrix to dramatically reduce cold flow and increase mechanical strength.

Expanded PTFE (ePTFE) has a multidirectional fibrous structure that resists cold flow while remaining highly conformable. It can create a tight seal on irregular or delicate flanges with much lower bolt load, making it a superior choice for many demanding applications.

Choosing the Right PTFE for Your Application

Selecting the correct type of PTFE is about matching the material's properties to the specific demands of your service.

- If your primary focus is extreme chemical resistance in a low-pressure system: Virgin PTFE is an excellent and cost-effective choice for its purity and inertness.

- If your application involves high pressure or significant thermal cycling: A filled or expanded PTFE (ePTFE) is essential to mitigate cold flow and ensure a durable, long-lasting seal.

- If you need to seal delicate or irregular flanges (like glass-lined steel or plastic): Highly conformable expanded PTFE (ePTFE) is the ideal choice, as it seals effectively with minimal compressive force.

- If your process involves food, beverage, or pharmaceuticals: Ensure your selected PTFE material is specifically certified to meet FDA, NSF, or other relevant industry standards.

By matching the specific type of PTFE to your operational demands, you can leverage its remarkable properties while effectively managing its inherent limitations.

Summary Table:

| Key Advantage | Description |

|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, acids, and caustics. |

| Thermal Stability | Operates from -240°C to 260°C, ideal for cryogenic to high-heat applications. |

| Non-Stick Surface | Low friction prevents media adhesion, ensuring easy cleaning and purity. |

| Electrical Insulation | Excellent dielectric properties prevent current conduction and corrosion. |

| Regulatory Compliance | Meets FDA/NSF standards for food, pharmaceutical, and beverage industries. |

Need PTFE gaskets that withstand your toughest conditions? KINTEK specializes in precision PTFE components (seals, liners, labware) for semiconductor, medical, laboratory, and industrial applications. We offer custom fabrication from prototypes to high-volume orders, ensuring your gaskets deliver unmatched chemical resistance, thermal stability, and compliance. Contact us today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE coating enhance corrosion resistance in fasteners? Achieve Unmatched Protection in Harsh Environments

- Can you provide an example comparing PTFE and PTFE envelope gaskets in a practical scenario? Ensure a Reliable Seal in Demanding Applications

- How does the compressibility of ePTFE gaskets benefit sealing applications? Achieve Superior, Leak-Free Seals

- What are the maintenance requirements for PTFE slide bearings? Ensure Long-Term, Maintenance-Free Performance

- What are the challenges of cleaning Teflon residue from a screw and barrel? A Guide to Safe, Effective Removal

- What raw material is used to manufacture PTFE spacers? Discover the Power of Teflon for High-Performance Components

- What material is replacing carbon in seals and piston rings, and why? PTFE's Superior Durability & Lifespan

- How should PTFE laminated bearing pads be installed? A Guide to Precision Installation for Bridge Movement