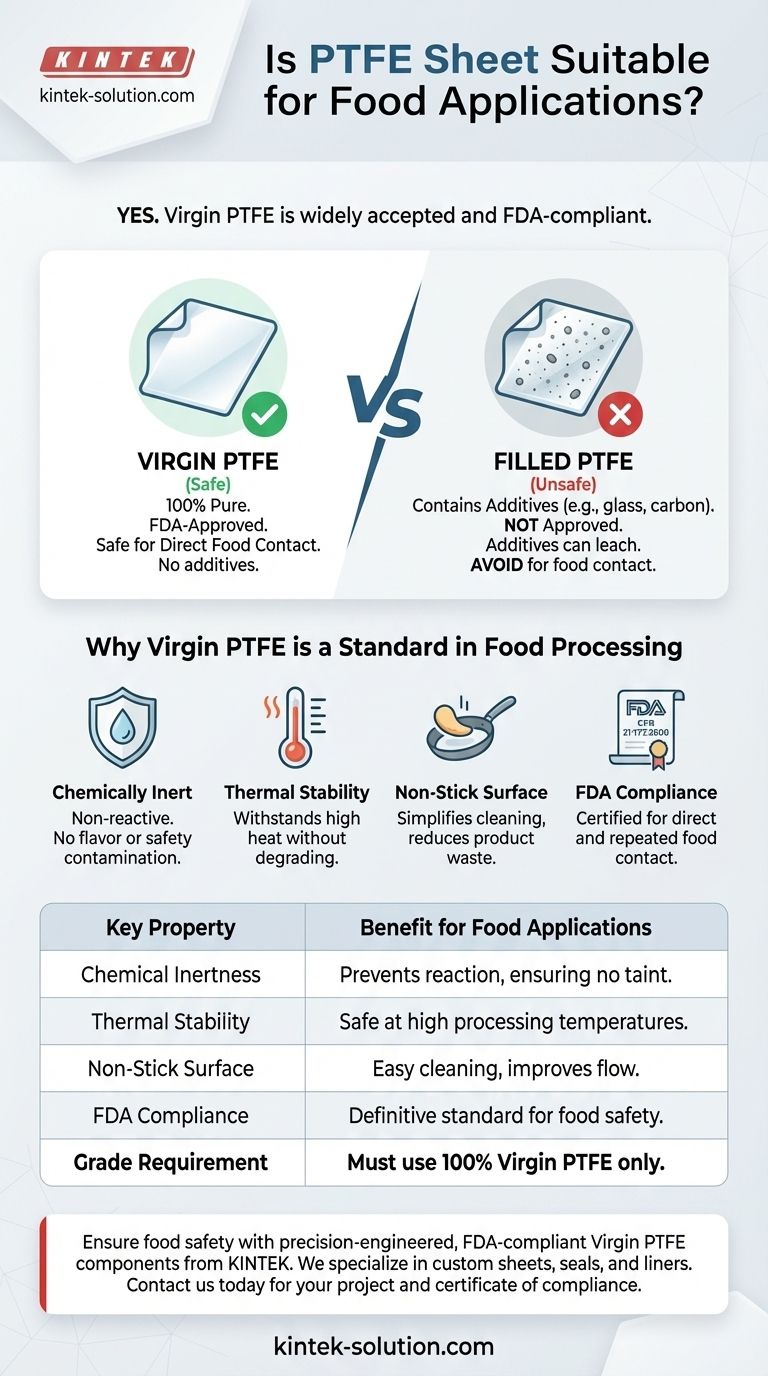

In short, yes. Virgin Polytetrafluoroethylene (PTFE) sheet is not only suitable but is a widely accepted and trusted material for food applications. It is chemically inert and complies with strict FDA regulations for materials intended for direct food contact.

The suitability of PTFE for food applications hinges on one critical factor: its grade. While 100% pure "virgin" PTFE is FDA-approved and safe, "filled" grades containing additives are not and must be avoided for any surface that touches food.

Why Virgin PTFE is a Standard in Food Processing

The properties that make PTFE a high-performance industrial material also make it exceptionally well-suited for the demanding, safety-critical environment of food production and packaging.

Unmatched Chemical Inertness

Virgin PTFE is one of the most non-reactive materials known. It does not react with, corrode from, or leach into food products, even acidic or caustic ones.

This stability ensures that the PTFE components will not taint the food's flavor, color, or safety.

Exceptional Thermal Stability

PTFE maintains its integrity across a very wide range of temperatures. It can withstand the high heat common in cooking and processing applications without degrading or releasing harmful substances.

Superior Non-Stick Surface

Famously known for its use in non-stick cookware, PTFE's low-friction surface is a major advantage in food processing.

This property prevents food from sticking to machinery components like liners, chutes, and guides, which simplifies cleaning, improves flow, and reduces product waste.

Compliance and FDA Approval

Virgin PTFE complies with FDA regulation CFR 21-177.2600, which governs "Rubber articles intended for repeated use" in producing, manufacturing, packing, processing, preparing, treating, packaging, transporting, or holding food. This certification is the definitive standard for food-contact safety.

Understanding the Trade-offs: Virgin vs. Filled PTFE

Failing to distinguish between PTFE grades is the most common and critical mistake when specifying this material for a food-related application.

The Purpose of "Filled" PTFE

In some industrial applications, additives like glass, carbon, or bronze are mixed into the PTFE resin before it is formed. These "fillers" enhance mechanical properties like wear resistance, compressive strength, or thermal conductivity.

Why Filled Grades Are Unsuitable for Food Contact

The additives used in filled PTFE are not approved for food contact. These fillers can leach out of the material over time, potentially contaminating or discoloring the food product.

For this reason, any filled grade of PTFE is immediately disqualified for direct contact with food.

How to Ensure You Have the Correct Grade

When sourcing PTFE sheet for a food application, you must explicitly specify 100% virgin grade PTFE. Always demand a certificate of compliance from your supplier that confirms the material meets FDA standards for food contact.

Making the Right Choice for Your Application

Use your specific goal to guide your material selection and verification process.

- If your primary focus is direct food contact: Always specify and verify you are using 100% virgin, FDA-compliant PTFE.

- If your primary focus is mechanical performance in a non-contact area: A filled PTFE grade might offer better wear resistance, but it must be physically isolated from the food stream.

- If your primary focus is compliance and safety: Always request a certificate of compliance from your supplier that explicitly states FDA approval.

By understanding the distinction between grades, you can confidently leverage the powerful benefits of PTFE while ensuring absolute food safety.

Summary Table:

| Key Property | Benefit for Food Applications |

|---|---|

| Chemical Inertness | Prevents reaction with food, ensuring no flavor or safety contamination |

| Thermal Stability | Withstands high heat without degrading or releasing harmful substances |

| Non-Stick Surface | Reduces product waste and simplifies cleaning of machinery |

| FDA Compliance (CFR 21-177.2600) | Certified safe for direct and repeated food contact |

| Grade Requirement | Must use 100% virgin PTFE; filled grades are unsuitable for food contact |

Ensure food safety and efficiency with precision-engineered PTFE components from KINTEK.

We specialize in manufacturing custom FDA-compliant virgin PTFE sheets, seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our commitment to precision production guarantees materials that meet strict food safety standards.

Contact us today to discuss your project requirements and receive a certificate of compliance for your peace of mind.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the benefits of using PTFE seals in demanding industries? Solve Extreme Sealing Challenges

- What are the advantages of solid Teflon O-rings? Achieve Unmatched Chemical & Thermal Resistance

- How does a Labyrinth PTFE Seal work? Achieve Frictionless, Long-Term Reliability

- What are the characteristics of PTFE spherical balls? Key Properties for Demanding Applications

- What is a PTFE bush and what is its primary use? A Guide to Self-Lubricating Bearings

- How does the lining of PTFE/PFA lined ball valves provide corrosion resistance? A Guide to Superior Chemical Handling

- What are the advantages and disadvantages of PTFE Lined Ball Valves? Specialized Corrosion Control for Your Process

- How does the chemical stability of PTFE oil seals compare to conventional oil seals? Superior Performance in Harsh Environments