The primary advantages of solid Teflon O-rings are rooted in the material's fundamental properties. They offer exceptional resistance to nearly all industrial chemicals and can operate across an extremely wide temperature range. Additionally, their inherently low coefficient of friction makes them highly durable in specific applications where minimal wear is critical.

While solid Teflon O-rings provide unmatched chemical and thermal resistance, their key advantage is also their biggest limitation: rigidity. This makes them ideal for static, high-stakes applications with precise tolerances but often unsuitable for dynamic seals that require elasticity.

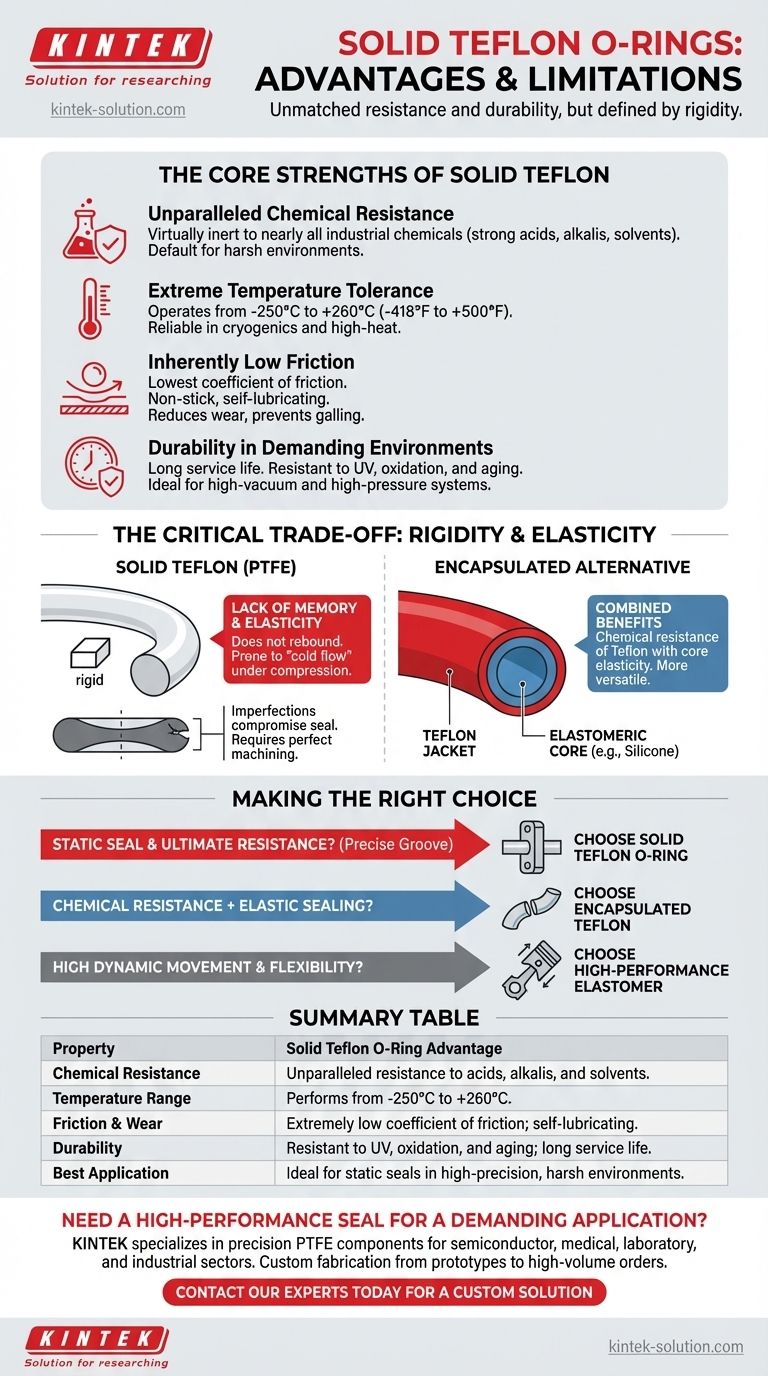

The Core Strengths of Solid Teflon

Unparalleled Chemical Resistance

Solid Teflon (PTFE) is one of the most chemically inert materials available. It is virtually unaffected by aggressive chemicals, including strong acids, alkalis, and organic solvents.

This makes it the default choice for sealing applications in harsh chemical processing, pharmaceutical, and laboratory environments where other elastomers would rapidly degrade.

Extreme Temperature Tolerance

Solid Teflon O-rings function reliably across a vast temperature spectrum, typically from -250°C to +260°C (-418°F to +500°F).

This allows them to be used in cryogenic processes as well as high-temperature systems where materials like silicone or Viton would fail.

Inherently Low Friction

Teflon possesses one of the lowest coefficients of friction of any solid material, giving it a non-stick, self-lubricating quality.

While not ideal for traditional dynamic sealing, this property reduces wear and prevents galling in applications with slow or infrequent movement. It also ensures parts do not stick together after long periods of contact.

Durability in Demanding Environments

The combination of chemical inertness and temperature stability results in a very long service life. Solid Teflon O-rings do not degrade from UV exposure, oxidation, or aging.

This makes them suitable for use in high-vacuum systems, high-pressure flanges, and other critical applications where seal failure is not an option.

Understanding the Critical Trade-offs

The Lack of Elasticity

The most significant limitation of a solid Teflon O-ring is its lack of memory and elasticity. Unlike a rubber O-ring, it does not compress and rebound to maintain a constant sealing force.

Once compressed, it tends to hold its shape, a phenomenon known as "cold flow" or creep. This means it cannot easily compensate for surface imperfections or thermal expansion and contraction.

Implications for Sealing Performance

Because it is rigid, a solid Teflon O-ring requires a perfectly machined groove and mating surface to create an effective seal.

Any minor imperfections, vibrations, or pressure fluctuations can compromise the seal, as the O-ring cannot flex to adapt. This makes them best suited for static face seals rather than dynamic piston or rod seals.

The Encapsulated Teflon Alternative

To overcome the rigidity problem, encapsulated O-rings were developed. These feature a flexible elastomeric core (like Silicone or FKM) inside a thin, seamless Teflon jacket.

This design combines the chemical resistance of Teflon with the elasticity of the core material, providing a much more versatile sealing solution for a wider range of applications.

Making the Right Choice for Your Application

Choosing the correct seal requires understanding the fundamental trade-off between absolute resistance and functional flexibility.

- If your primary focus is ultimate chemical and temperature resistance in a static seal: A solid Teflon O-ring is the superior choice, provided your groove design and surface finish are precise.

- If you need chemical resistance combined with reliable, elastic sealing force: An encapsulated Teflon O-ring offers a far better balance of properties and is more forgiving of minor imperfections.

- If your application involves significant dynamic movement or requires high flexibility: A standard high-performance elastomer is likely the more appropriate and reliable solution.

Ultimately, understanding the inherent rigidity of solid Teflon is the key to leveraging its advantages without encountering its significant sealing limitations.

Summary Table:

| Property | Solid Teflon O-Ring Advantage |

|---|---|

| Chemical Resistance | Unparalleled resistance to acids, alkalis, and solvents. |

| Temperature Range | Performs from -250°C to +260°C (-418°F to +500°F). |

| Friction & Wear | Extremely low coefficient of friction; self-lubricating. |

| Durability | Resistant to UV, oxidation, and aging; long service life. |

| Best Application | Ideal for static seals in high-precision, harsh environments. |

Need a high-performance seal for a demanding application?

KINTEK specializes in manufacturing precision PTFE components, including solid Teflon O-rings, for the semiconductor, medical, laboratory, and industrial sectors. We provide custom fabrication from prototypes to high-volume orders, ensuring your seals meet the exact chemical and thermal resistance requirements of your critical systems.

Contact our experts today to discuss your specific needs and get a custom solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments