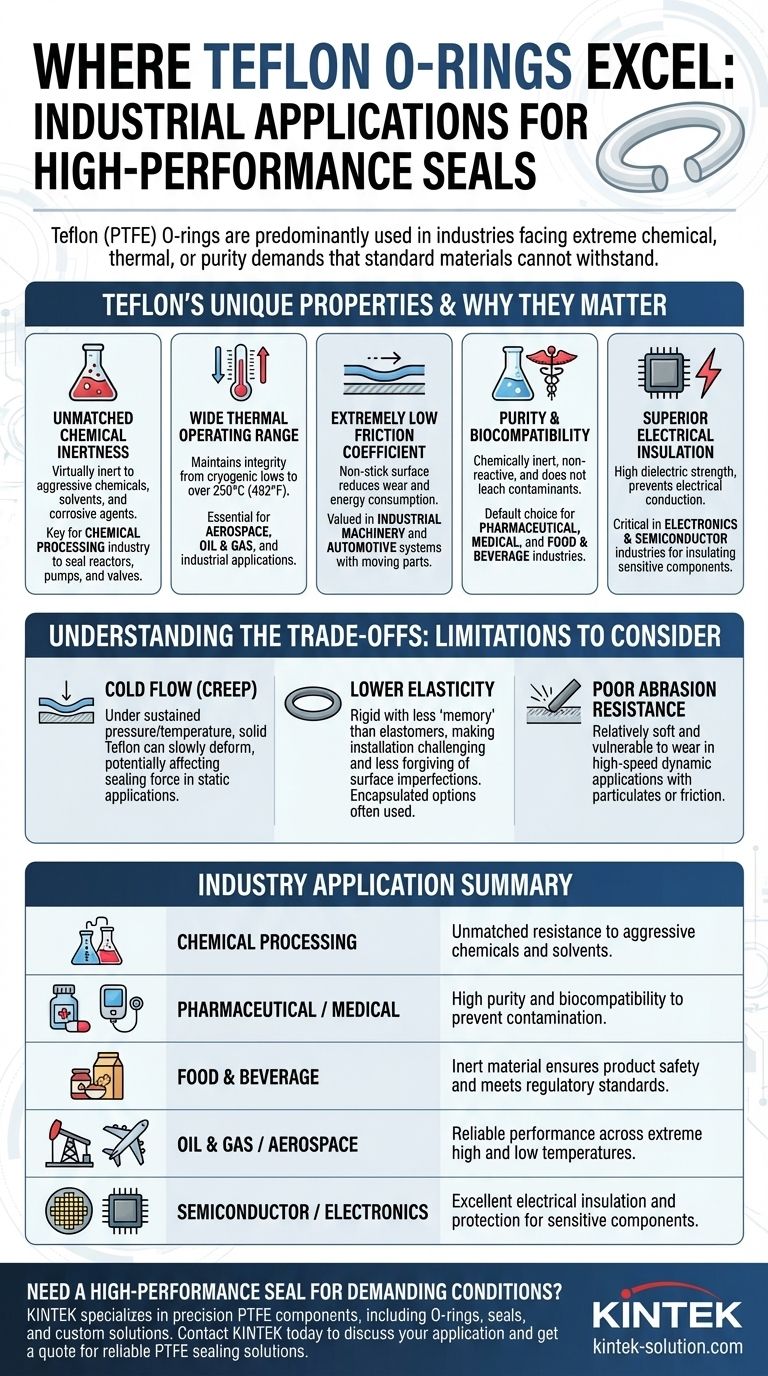

In short, Teflon (PTFE) O-rings are predominantly used in industries where seals face extreme chemical, thermal, or purity demands that would cause standard materials to fail. The most common sectors include chemical processing, oil and gas, pharmaceuticals, food and beverage, and electronics manufacturing due to Teflon's unique combination of properties.

The specific industry is less important than the application's environment. Teflon is not a general-purpose solution; it is a high-performance specialty material chosen when conditions involving aggressive chemicals, extreme temperatures, or the need for absolute purity make conventional elastomers unsuitable.

Why Teflon Excels in Demanding Environments

The widespread adoption of Teflon across various critical industries is not accidental. It stems from a unique set of material properties that solve problems other sealing materials simply cannot. Understanding these core strengths is key to knowing when a Teflon O-ring is the correct engineering choice.

Unmatched Chemical Inertness

Teflon is virtually inert to almost all industrial chemicals, solvents, and corrosive agents. This makes it an essential material in the chemical processing industry.

It is used to seal reactors, pumps, and valves that handle highly aggressive substances, ensuring both system integrity and safety where a standard rubber O-ring would quickly degrade and fail.

Wide Thermal Operating Range

Teflon maintains its structural integrity across an exceptionally broad temperature spectrum, from cryogenic lows to highs exceeding 250°C (482°F).

This thermal stability makes it indispensable in aerospace, oil and gas, and industrial applications where equipment cycles between extreme temperatures while requiring a reliable seal.

Extremely Low Friction Coefficient

Teflon has one of the lowest coefficients of friction of any solid material, creating a "non-stick" surface.

This property is highly valued in applications with moving parts, such as in industrial machinery and automotive systems, as it reduces wear, prevents seizing, and lowers the energy required for operation.

Purity and Biocompatibility

Because Teflon is chemically inert and non-reactive, it does not leach contaminants into the substances it contacts.

This makes it a default choice for the pharmaceutical, medical, and food and beverage industries, where preventing product contamination is a non-negotiable requirement for safety and regulatory compliance.

Superior Electrical Insulation

Teflon is an excellent electrical insulator with high dielectric strength, meaning it can withstand high voltages without conducting electricity.

This property is critical in the electronics and semiconductor industries for sealing and insulating components, protecting sensitive circuits from environmental factors and electrical interference.

Understanding the Trade-offs

While its strengths are significant, Teflon is not a universal solution. An objective assessment requires acknowledging its limitations, which can be critical depending on the application.

Susceptibility to Cold Flow (Creep)

Under sustained pressure and temperature, solid Teflon can slowly deform over time, a phenomenon known as creep or cold flow.

This means that in high-pressure static sealing applications, the O-ring may gradually lose its sealing force, potentially leading to leaks.

Lower Elasticity

Compared to rubber elastomers like Viton or Nitrile, solid Teflon O-rings are rigid and have very little elasticity or "memory."

This makes them more challenging to install and less forgiving of imperfections on sealing surfaces. Encapsulated O-rings—with a flexible core and a Teflon jacket—are often used to overcome this limitation.

Poor Abrasion Resistance

Teflon is a relatively soft material and does not stand up well to abrasive media or high-speed dynamic applications.

In environments with particulates or significant friction, a Teflon O-ring can wear down much faster than harder materials, making it unsuitable for certain types of dynamic seals.

Making the Right Choice for Your Goal

Selecting the correct sealing material requires matching its properties to the primary challenge of your application.

- If your primary focus is resisting aggressive chemicals: Teflon is almost always the superior choice, providing reliability where other materials would dissolve.

- If your primary focus is handling extreme temperatures (high or low): Teflon provides a stable and predictable sealing solution across a wider range than most elastomers.

- If your primary focus is ensuring absolute purity: Teflon is the industry standard for food, medical, and semiconductor applications where preventing contamination is critical.

- If your primary focus is a high-pressure dynamic seal: Carefully evaluate Teflon's limitations regarding creep and abrasion; an energized Teflon seal or a different high-performance polymer may be a better fit.

Ultimately, a Teflon O-ring is a specialist's tool, engineered to perform reliably in conditions that push beyond the limits of conventional materials.

Summary Table:

| Industry | Primary Reason for Using Teflon O-rings |

|---|---|

| Chemical Processing | Unmatched resistance to aggressive chemicals and solvents. |

| Pharmaceutical / Medical | High purity and biocompatibility to prevent contamination. |

| Food & Beverage | Inert material ensures product safety and meets regulatory standards. |

| Oil & Gas / Aerospace | Reliable performance across extreme high and low temperatures. |

| Semiconductor / Electronics | Excellent electrical insulation and protection for sensitive components. |

Need a high-performance seal for demanding conditions?

KINTEK specializes in manufacturing precision PTFE components, including O-rings, seals, liners, and custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we provide solutions that handle extreme chemical, thermal, and purity challenges.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact KINTEK today to discuss your application and get a quote for reliable PTFE sealing solutions.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How do Teflon and nylon washers differ? Choose the Right Washer for Your Application

- What advantages do PTFE spring-energized seals offer in harsh environments? Unlock Unmatched Reliability

- What temperature limitations exist for PTFE lined butterfly valves? Ensure Safe, Leak-Free Operation

- Why is the quality of PTFE resin important for structured and expanded PTFE? Ensure Long-Term Sealing Integrity

- What mechanical properties make PTFE bellows durable for critical applications? Ensure Long-Term Reliability in Demanding Environments

- What are some application examples of PTFE O-ring seals in mechanical equipment? Solve Extreme Sealing Challenges

- What temperature limitations should be considered when using PTFE lined butterfly valves? Ensure Safe & Reliable Operation

- What is the role of PTFE backup rings in sealing applications? Prevent Seal Extrusion Under High Pressure