The primary advantage of PTFE spring-energized seals is their ability to provide a consistently reliable seal in environments where traditional elastomeric seals would fail. They achieve this by combining the exceptional chemical and thermal resistance of a Polytetrafluoroethylene (PTFE) jacket with the constant mechanical force of an internal spring energizer, ensuring performance under extreme temperatures, high pressures, and contact with aggressive chemicals.

At its core, the design separates the material properties from the mechanical force. The PTFE jacket acts as an inert shield against the harsh environment, while the spring provides the adaptive muscle needed to maintain a tight seal despite wear, pressure changes, or thermal expansion.

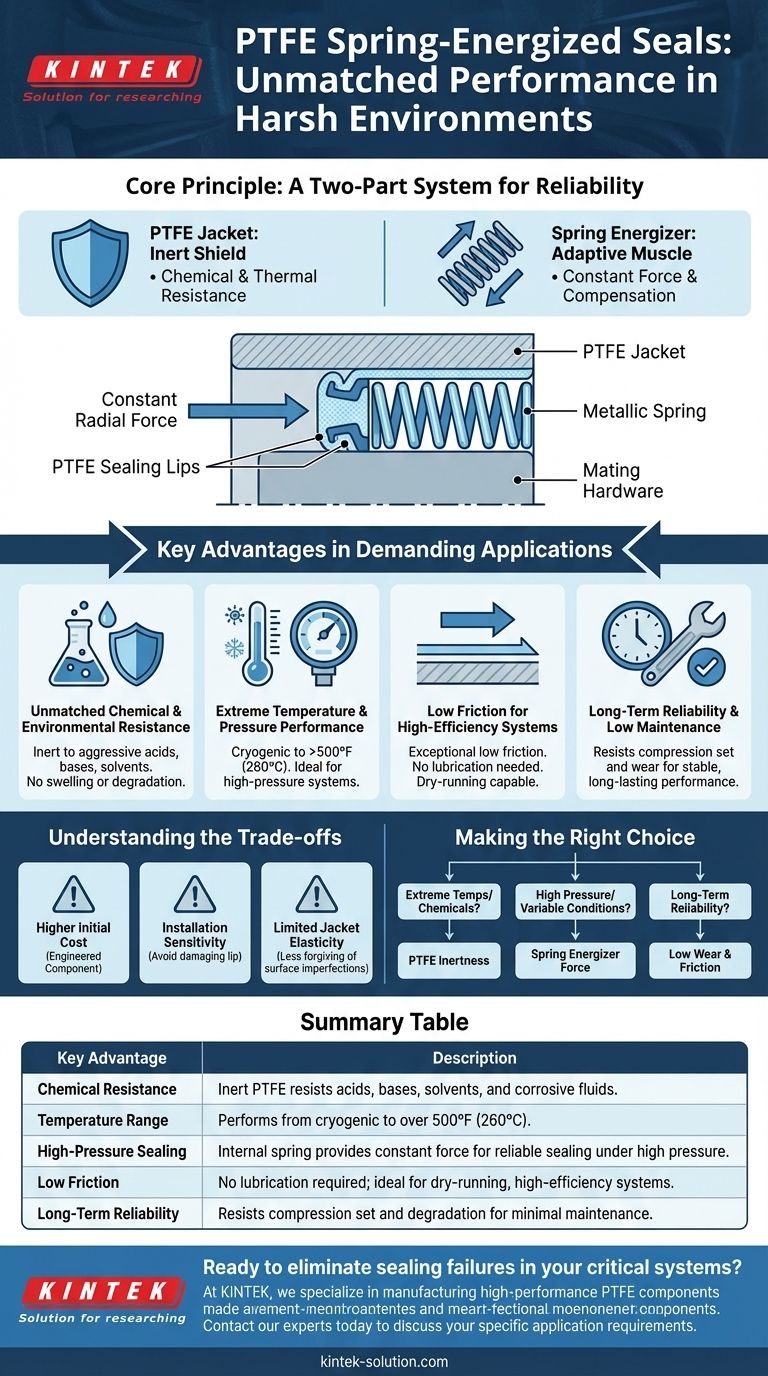

The Core Principle: A Two-Part System for Reliability

The effectiveness of these seals stems from how their two main components work in synergy. Understanding this relationship is key to appreciating their value in mission-critical systems.

The PTFE Jacket: Your Chemical and Thermal Shield

The outer seal jacket is made from a PTFE-based compound. This material is selected for its remarkable inherent properties.

It is almost universally chemically inert, meaning it will not degrade when exposed to aggressive acids, bases, solvents, or other corrosive fluids.

Furthermore, PTFE has an extremely wide operating temperature range. It remains functional and maintains its shape in cryogenic conditions and at continuous temperatures exceeding 500°F (260°C).

The Spring Energizer: The Engine of a Consistent Seal

Inside the PTFE jacket sits a metallic spring. This is the "energizer" that provides the seal's mechanical strength.

The spring exerts a constant radial force, pushing the PTFE sealing lips against the mating hardware. This ensures a tight seal even at very low system pressures.

Crucially, this spring force compensates for changing conditions. It accounts for dimensional changes caused by temperature fluctuations, adjusts for minor hardware misalignment, and continues to provide force even as the PTFE lip slowly wears over time.

Key Advantages in Demanding Applications

This two-part design delivers a unique set of benefits perfectly suited for the most challenging industrial environments, from petrochemical plants to aerospace systems.

Unmatched Chemical and Environmental Resistance

Because the sealing element is PTFE, the seal is unaffected by harsh media that would cause elastomers to swell, shrink, or dissolve. It is also resistant to weathering and environmental contaminants, giving it a long and stable shelf life.

Extreme Temperature and Pressure Performance

The combination of a thermally stable jacket and a resilient metal spring allows these seals to operate reliably where others cannot. They are a standard solution for high-pressure gas systems and liquefied natural gas (LNG) applications alike.

Low Friction for High-Efficiency Systems

PTFE has an exceptionally low coefficient of friction. This means the seal requires no lubrication and can be used in dry-running applications, reducing system complexity and contamination risk.

This low-friction characteristic also minimizes frictional heat buildup and energy loss, increasing the overall efficiency and longevity of the mechanical system.

Resistance to Compression Set and Degradation

Unlike rubber seals that can permanently deform under prolonged stress (a failure known as compression set), PTFE spring-energized seals maintain their form. The spring ensures the sealing lip always returns to its intended position, guaranteeing long-term, reliable performance without frequent replacement.

Understanding the Practical Trade-offs

While highly effective, these seals are specialized components. An objective analysis requires acknowledging their specific considerations.

Higher Initial Cost

PTFE spring-energized seals are engineered components and typically have a higher upfront cost compared to standard O-rings or other elastomeric seals. This cost is justified by their extended service life and performance in applications where seal failure would be catastrophic.

Installation Sensitivity

The PTFE jacket is a relatively hard plastic material compared to a soft rubber. Care must be taken during installation to avoid scratching or gouging the sealing lip, which could create a leak path. Proper installation tools and procedures are critical.

Limited Elasticity of the Jacket

The jacket material itself is not highly elastic. While the spring provides excellent adaptability, the seal is less forgiving of rough surface finishes or significant hardware imperfections compared to a highly compliant elastomer.

Making the Right Choice for Your Goal

Specifying the correct seal depends entirely on the demands of your application.

- If your primary focus is extreme temperatures or aggressive chemicals: The inertness and thermal stability of the PTFE jacket make this seal the most reliable choice.

- If your primary focus is high pressure or variable operating conditions: The spring energizer's ability to provide a constant, adaptive force ensures a consistent seal when others would fail.

- If your primary focus is long-term reliability and low maintenance: The combination of low wear, low friction, and resistance to compression set provides a fit-and-forget solution for critical systems.

Ultimately, a PTFE spring-energized seal is an engineering solution designed to eliminate sealing as a point of failure in your most demanding applications.

Summary Table:

| Key Advantage | Description |

|---|---|

| Chemical Resistance | Inert PTFE jacket resists acids, bases, solvents, and corrosive fluids. |

| Temperature Range | Performs from cryogenic to over 500°F (260°C). |

| High-Pressure Sealing | Internal spring provides constant force for reliable sealing under high pressure. |

| Low Friction | No lubrication required; ideal for dry-running, high-efficiency systems. |

| Long-Term Reliability | Resists compression set and degradation for minimal maintenance. |

Ready to eliminate sealing failures in your critical systems?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom spring-energized seals, for the semiconductor, medical, laboratory, and industrial sectors. Our precision production ensures your seals deliver unmatched reliability in the harshest environments, from prototypes to high-volume orders.

Contact our experts today to discuss your specific application requirements and discover the KINTEK difference in sealing solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs