In mechanical equipment, PTFE O-rings and seals are specified for a wide range of demanding applications including pumps, compressors, gearboxes, motors, and valves. They are also critical components in specialized machinery such as cryogenic systems, robotics, and various fluid transfer and processing systems where standard elastomers would quickly fail.

PTFE is not a universal replacement for standard rubber O-rings. It is a specialized sealing material chosen specifically for its ability to solve problems related to aggressive chemicals, extreme temperatures, and high-friction environments where other materials are unsuitable.

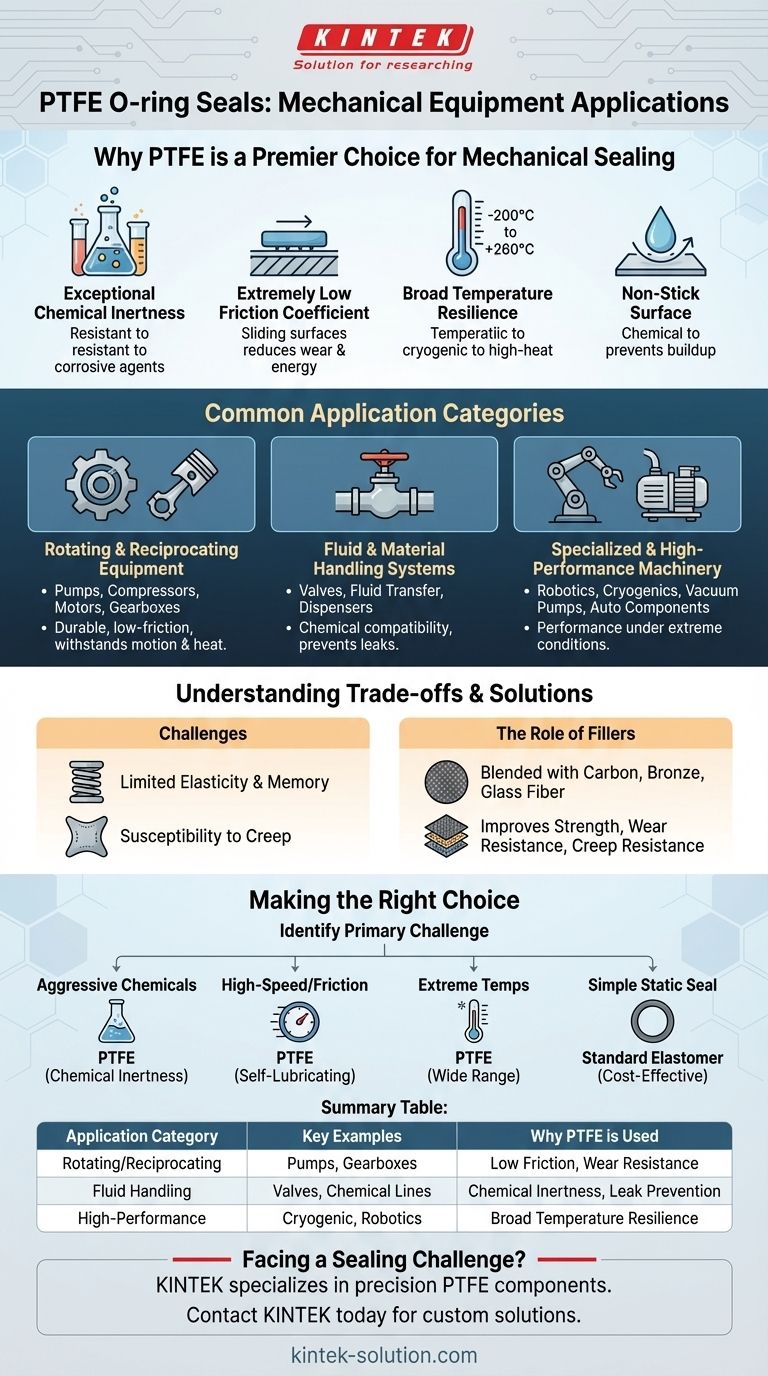

Why PTFE is a Premier Choice for Mechanical Sealing

The widespread use of Polytetrafluoroethylene (PTFE) in mechanical systems stems from a unique combination of material properties. Understanding these characteristics is key to recognizing when and why to specify a PTFE seal.

Exceptional Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, solvents, and corrosive agents. This makes it the default choice for sealing applications in chemical processing, fuel handling systems, and adhesive dispensing equipment.

Extremely Low Friction Coefficient

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating property is critical in dynamic applications like piston rings, bearings, and rotating shafts, as it significantly reduces wear, heat generation, and energy consumption.

Broad Temperature Resilience

PTFE seals maintain their integrity and performance across an exceptionally wide temperature range. This allows them to be used effectively in high-temperature gearboxes and engines as well as in cryogenic systems where most materials become brittle.

Non-Stick Surface Properties

The material's non-stick, or hydrophobic, nature prevents residue buildup from sticky or viscous media. This is essential in applications like food processing pumps and mixers, ensuring operational cleanliness and preventing contamination.

Common Application Categories

While the list of uses is extensive, most mechanical applications for PTFE seals fall into several key categories.

Rotating and Reciprocating Equipment

This is the most common category. Seals in pumps, compressors, motors, and gearboxes must withstand constant motion, heat, and lubricants. PTFE excels here by providing a durable, low-friction sealing surface that protects internal components from dust and moisture.

Fluid and Material Handling Systems

In systems that control the flow of media, chemical compatibility is paramount. PTFE seals are used extensively in valves, fluid transfer systems, and adhesive dispensers to prevent leaks and material degradation.

Specialized and High-Performance Machinery

The unique properties of PTFE make it indispensable in advanced equipment. It is found in robotics, cryogenic systems, vacuum pumps, and automotive components like fuel injection pumps and hydraulic systems, where performance under extreme conditions is non-negotiable.

Understanding the Trade-offs of PTFE

Despite its advantages, PTFE is not without limitations. Acknowledging these trade-offs is crucial for proper design and application.

Limited Elasticity and Memory

Unlike traditional elastomers, PTFE is a relatively rigid plastic. It has poor elastic memory, meaning it does not spring back to its original shape effectively after being compressed. This requires careful consideration of gland design and often necessitates the use of energizers (like a spring or rubber insert) to maintain a constant sealing force.

Susceptibility to Creep

Under a constant compressive load, especially at elevated temperatures, PTFE can slowly deform over time in a phenomenon known as "creep." This can eventually lead to a loss of sealing pressure and potential leaks.

The Role of Fillers

To counteract these mechanical weaknesses, PTFE is often blended with fillers. Adding materials like carbon, bronze, or glass fiber significantly improves the compound's strength, wear resistance, and resistance to creep, making it suitable for more mechanically demanding applications.

Making the Right Choice for Your Application

Selecting the correct sealing material requires you to identify the primary challenge your equipment faces.

- If your primary focus is resisting aggressive chemicals or solvents: PTFE is almost certainly the correct choice due to its near-universal chemical inertness.

- If your primary focus is reducing friction in high-speed rotating equipment: The self-lubricating nature of PTFE will extend component life and improve efficiency.

- If your primary focus is sealing in cryogenic or high-temperature environments: PTFE's wide operating temperature range makes it one of the few viable options.

- If your primary focus is a simple static seal with no challenging media: A standard, more cost-effective elastomer like Nitrile or Viton™ may be a more appropriate choice.

Ultimately, specifying a PTFE seal is a decision to leverage a high-performance material to solve engineering challenges that conventional seals cannot.

Summary Table:

| Application Category | Key Examples | Why PTFE is Used |

|---|---|---|

| Rotating/Reciprocating Equipment | Pumps, Compressors, Gearboxes | Low friction, wear resistance, heat tolerance |

| Fluid Handling Systems | Valves, Chemical Transfer Lines | Exceptional chemical inertness, prevents leaks |

| High-Performance/Specialized Machinery | Cryogenic Systems, Robotics, Vacuum Pumps | Broad temperature resilience, performance under extremes |

Facing a Sealing Challenge That Standard Elastomers Can't Handle?

KINTEK specializes in manufacturing precision PTFE components—including seals, O-rings, liners, and custom labware—for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

Whether you need a prototype for a new design or high-volume production of a proven solution, our expertise in custom PTFE fabrication ensures a perfect fit and superior performance. We help you overcome challenges with aggressive chemicals, extreme temperatures, and high-friction environments.

Contact KINTEB today to discuss your specific requirements and let our material science experts provide a solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments