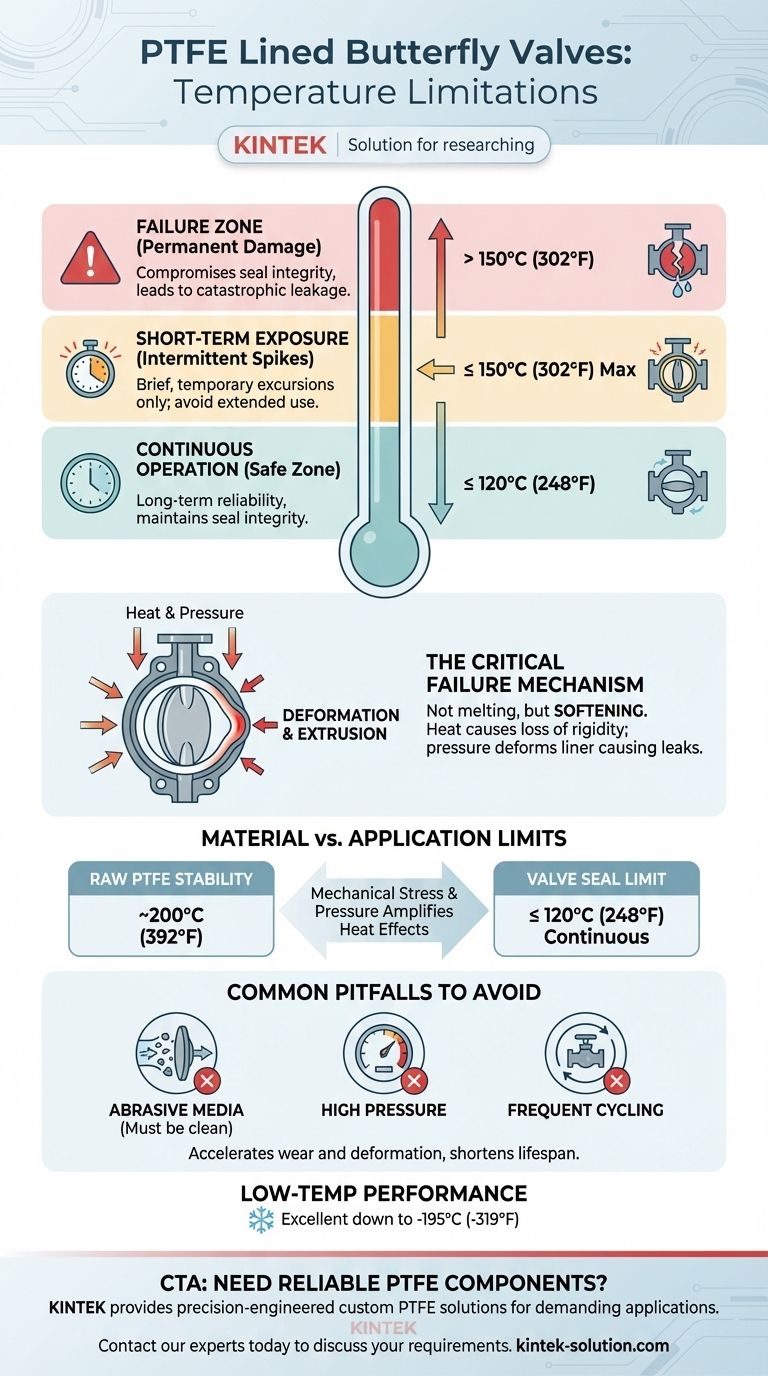

For safe and reliable long-term operation, a PTFE lined butterfly valve should be used with medium temperatures at or below 120°C (248°F). While the valve may tolerate brief, intermittent exposure to temperatures as high as 150°C (302°F), exceeding these thermal limits will compromise the integrity of the seal and lead to failure.

The critical takeaway is that the effective temperature limit of a PTFE lined valve is dictated by the material's ability to maintain a mechanical seal under pressure, not by its theoretical melting point. High temperatures cause the PTFE to soften and deform, leading to catastrophic leakage long before the material itself breaks down.

Understanding the Temperature Ratings

To properly specify a PTFE lined butterfly valve, it's essential to distinguish between its continuous and intermittent temperature capabilities. These limits are in place to prevent a specific type of mechanical failure.

The Continuous Operating Limit

For any application involving long-term or steady-state use, the medium's temperature should not exceed 120°C (248°F). Operating at or below this temperature ensures the PTFE liner remains rigid enough to maintain its shape and provide a reliable, leak-proof seal over thousands of cycles.

The Short-Term Exposure Limit

The valve can handle brief, temporary spikes up to 150°C (302°F). This is not a continuous operating rating. Subjecting the valve to this temperature for extended periods will cause permanent damage.

The Critical Failure Mechanism

The primary mode of failure at high temperatures is not melting, but softening and deformation. As PTFE heats up, it loses its structural rigidity. The pressure from the valve disc closing against the liner can then cause the softened material to extrude or deform, preventing the valve from closing properly and resulting in significant leakage.

Why You See Conflicting Temperature Ranges

It is common to find technical literature stating that pure PTFE is stable up to 200°C (392°F) or even higher. This discrepancy creates confusion but highlights a critical engineering principle.

Material Properties vs. Application Limits

A raw material's thermal stability is very different from its performance limit within a mechanical assembly. While a sheet of PTFE might not degrade at 200°C, a PTFE valve liner under the constant mechanical stress of creating a seal will fail at a much lower temperature. The pressure applied by the system and the valve's own operation amplifies the negative effects of heat-induced softening.

Excellent Low-Temperature Performance

On the other end of the spectrum, PTFE demonstrates exceptional performance at cryogenic temperatures. It retains its flexibility and sealing properties in environments as cold as -195°C (-319°F), making it suitable for a wide range of low-temperature applications.

Common Pitfalls to Avoid

Temperature is the primary consideration, but other factors can dramatically impact the valve's performance and longevity. Ignoring them can lead to premature failure even when operating within the correct thermal range.

The Nature of the Medium

PTFE is a relatively soft material. The process medium must not contain hard particles, crystals, or other abrasive impurities. These particles can get trapped between the disc and the liner, causing scratches, gouges, and wear that will compromise the seal and lead to leakage.

Ignoring Pressure and Cycling

High system pressures and frequent open/close cycling both increase the mechanical stress on the PTFE liner. When operating near the upper end of the temperature range, high pressure or frequent cycling will accelerate the liner's deformation and significantly shorten the valve's service life.

Making the Right Choice for Your Application

Use these guidelines to ensure you are selecting a valve that is safe and appropriate for your specific operational context.

- If your primary focus is maximum reliability and longevity: Strictly adhere to a continuous operating temperature at or below 120°C (248°F).

- If your process involves occasional, brief temperature spikes: Verify that these excursions are short and never exceed the absolute maximum of 150°C (302°F).

- If your continuous operating temperature is above 120°C: A standard PTFE lined butterfly valve is the wrong choice and you must investigate valves with different liner materials.

- If your medium is not perfectly clean: You must prioritize upstream filtration or select a more robust valve type designed for abrasive service.

By respecting these practical engineering limits, you ensure the valve will provide safe, leak-free service for its entire intended lifespan.

Summary Table:

| Temperature Rating | Limit | Key Consideration |

|---|---|---|

| Continuous Operation | ≤ 120°C (248°F) | Ensures long-term seal integrity and reliability. |

| Short-Term/Intermittent | ≤ 150°C (302°F) | Brief exposure only; extended periods cause permanent damage. |

| Failure Mechanism | Softening & Deformation | High heat causes PTFE to soften, leading to seal extrusion and leakage under pressure. |

Need a reliable PTFE component for your demanding application?

At KINTEK, we understand that performance hinges on precision engineering and material integrity. Our custom-fabricated PTFE components—including seals, liners, and labware—are manufactured to meet the exacting standards of the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production to ensure your components perform reliably under specified thermal and mechanical conditions, from prototypes to high-volume orders.

Ensure your system's reliability. Contact our experts today to discuss your specific requirements and how our PTFE solutions can benefit your operation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How does carbon filler cause corrosion when combined with aluminum? Understanding Galvanic Corrosion Risks

- How does the shrinkage performance of PTFE gaskets affect their functionality? Ensure a Perfect, Leak-Free Seal

- Why are Teflon gland fillers suitable for food and beverage processing? Ensure Purity and Reliability

- What temperature range can PTFE-lined butterfly valves withstand? Ensuring Safe & Reliable Operation

- What are the special considerations for CNC machining PTFE? Master the Art of Precision Machining

- How does PTFE gland packing differ from other PTFE packing types? Discover the Right Sealing Solution

- What is the coefficient of friction for these o-rings? Don't Be Misled by a Single Number

- What are the primary advantages of Teflon washers compared to metal washers? Unlock Superior Performance in Harsh Environments