The fundamental difference between Teflon and nylon washers is their reaction to moisture and chemicals. Teflon (PTFE) is hydrophobic and chemically inert, making it ideal for wet, corrosive, or low-friction applications. Nylon is a strong, tough material for general use, but it is hydrophilic, meaning it absorbs water, which can alter its mechanical and electrical properties.

The decision between Teflon and nylon is an environmental one. Teflon excels in harsh conditions involving moisture, chemicals, or heat. Nylon provides excellent mechanical strength for general-purpose applications, provided the environment is relatively dry and stable.

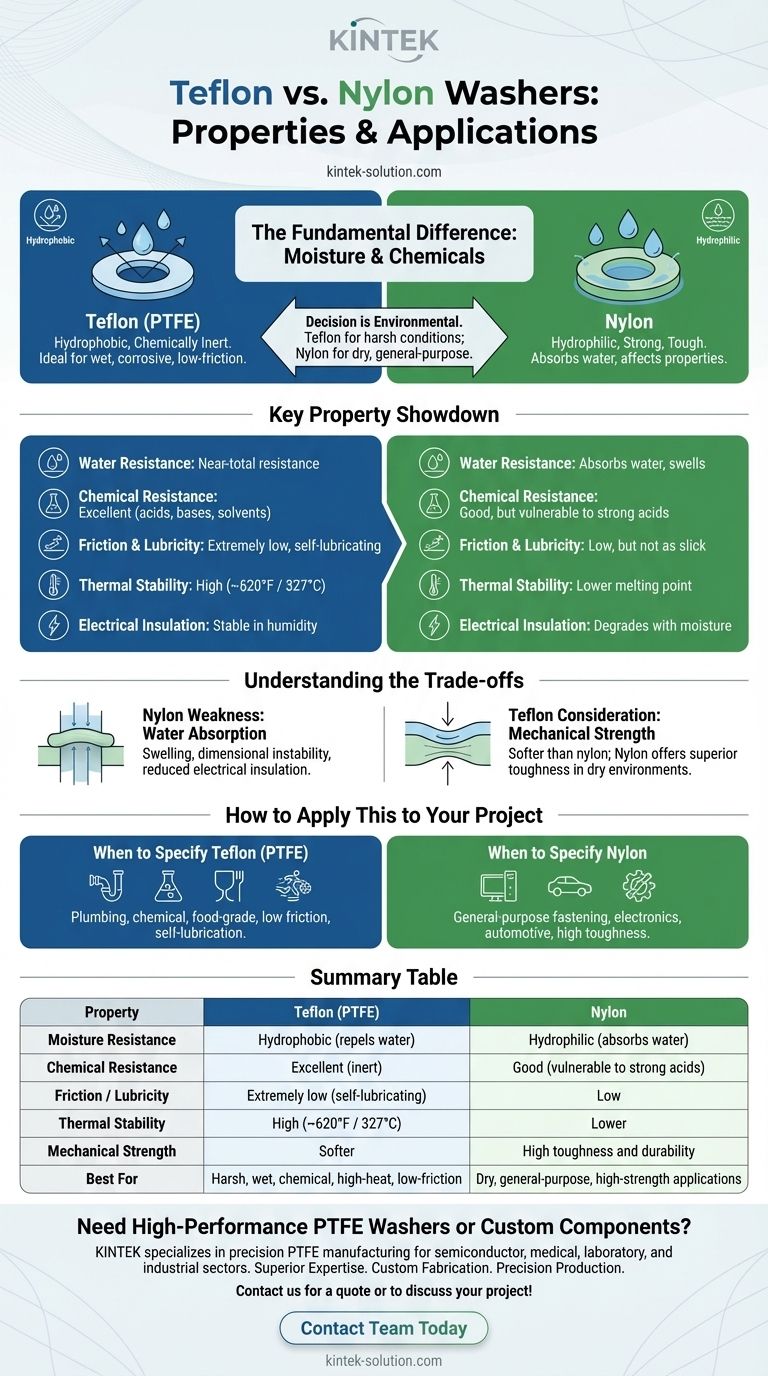

Key Property Showdown: Teflon vs. Nylon

To make an informed choice, you must understand how their core properties translate to real-world performance.

Water and Moisture Resistance

Teflon is hydrophobic, meaning it actively repels water and other liquids. This gives it near-total resistance to moisture.

Nylon is hydrophilic, meaning it readily absorbs water from its environment. This absorption can cause the material to swell and change its dimensions.

Chemical and Corrosion Resistance

Teflon is one of the most chemically inert plastics available. It offers reliable, excellent resistance against a vast range of acids, bases, and solvents.

Nylon has good chemical resistance to many common substances but is vulnerable to strong acids and oxidizing agents. Teflon is the superior choice for chemically aggressive environments.

Friction and Lubricity

Teflon has an extremely low coefficient of friction, making it one of the most "slippery" solid materials known. This makes it a self-lubricating washer, perfect for moving parts.

Nylon has a low coefficient of friction but is not as slick as Teflon. It is tough but does not provide the same level of natural lubricity.

Thermal Stability

Teflon possesses a very high melting point, around 620°F (327°C). This allows it to perform reliably in high-temperature applications.

Nylon's melting point is significantly lower, making it less suitable for high-heat environments compared to Teflon.

Electrical Insulation

Both materials are excellent electrical insulators. However, Teflon's properties remain stable regardless of humidity.

Because nylon absorbs moisture, its electrical insulating properties can degrade in humid environments as water content increases.

Understanding the Trade-offs

No material is perfect for every situation. Understanding their inherent limitations is crucial for avoiding component failure.

The Weakness of Nylon: Water Absorption

The primary drawback of nylon is its tendency to absorb water. This can lead to dimensional instability (swelling) and a reduction in its effectiveness as an electrical insulator. In a design with tight tolerances, this swelling can cause parts to bind or fail.

The Consideration for Teflon: Mechanical Strength

While Teflon's chemical and thermal properties are superb, it is a softer material than nylon. In purely mechanical applications that require high tensile strength or abrasion resistance in a dry environment, nylon often provides superior toughness and durability.

How to Apply This to Your Project

Your application's operating conditions will be the ultimate guide to your material choice.

When to Specify Teflon (PTFE)

Teflon is the definitive choice for applications in plumbing, chemical processing, and food-grade equipment (as it is FDA-approved). It is also ideal for any joint or mechanism requiring low friction and self-lubrication.

When to Specify Nylon

Nylon is an excellent, cost-effective choice for general-purpose fastening in controlled, dry environments. This includes electronics assembly, automotive components, and standard mechanical builds where high toughness is valued over environmental resistance.

Making the Right Choice for Your Goal

- If your primary focus is performance in wet or chemical environments: Teflon is the only reliable choice due to its hydrophobic and inert nature.

- If your primary focus is reducing friction between moving parts: Teflon's self-lubricating properties are superior.

- If your primary focus is a tough, low-cost fastener in a dry environment: Nylon provides excellent mechanical strength and durability.

By matching the material's inherent properties to your application's environment, you ensure the long-term reliability and success of your design.

Summary Table:

| Property | Teflon (PTFE) | Nylon |

|---|---|---|

| Moisture Resistance | Hydrophobic (repels water) | Hydrophilic (absorbs water) |

| Chemical Resistance | Excellent (inert) | Good (vulnerable to strong acids) |

| Friction / Lubricity | Extremely low (self-lubricating) | Low |

| Thermal Stability | High (melting point ~620°F / 327°C) | Lower |

| Mechanical Strength | Softer | High toughness and durability |

| Best For | Harsh, wet, chemical, high-heat, low-friction | Dry, general-purpose, high-strength applications |

Need High-Performance PTFE Washers or Custom Components?

Selecting the right material is critical for your project's success. KINTEK specializes in the precision manufacturing of PTFE components, including seals, liners, and labware, for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We offer:

- Superior Material Expertise: Ensure reliability in harsh environments.

- Custom Fabrication: From prototypes to high-volume orders.

- Precision Production: Guaranteed quality and performance.

Let us provide the perfect solution for your specific needs. Contact our team today for a quote or to discuss your project!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments