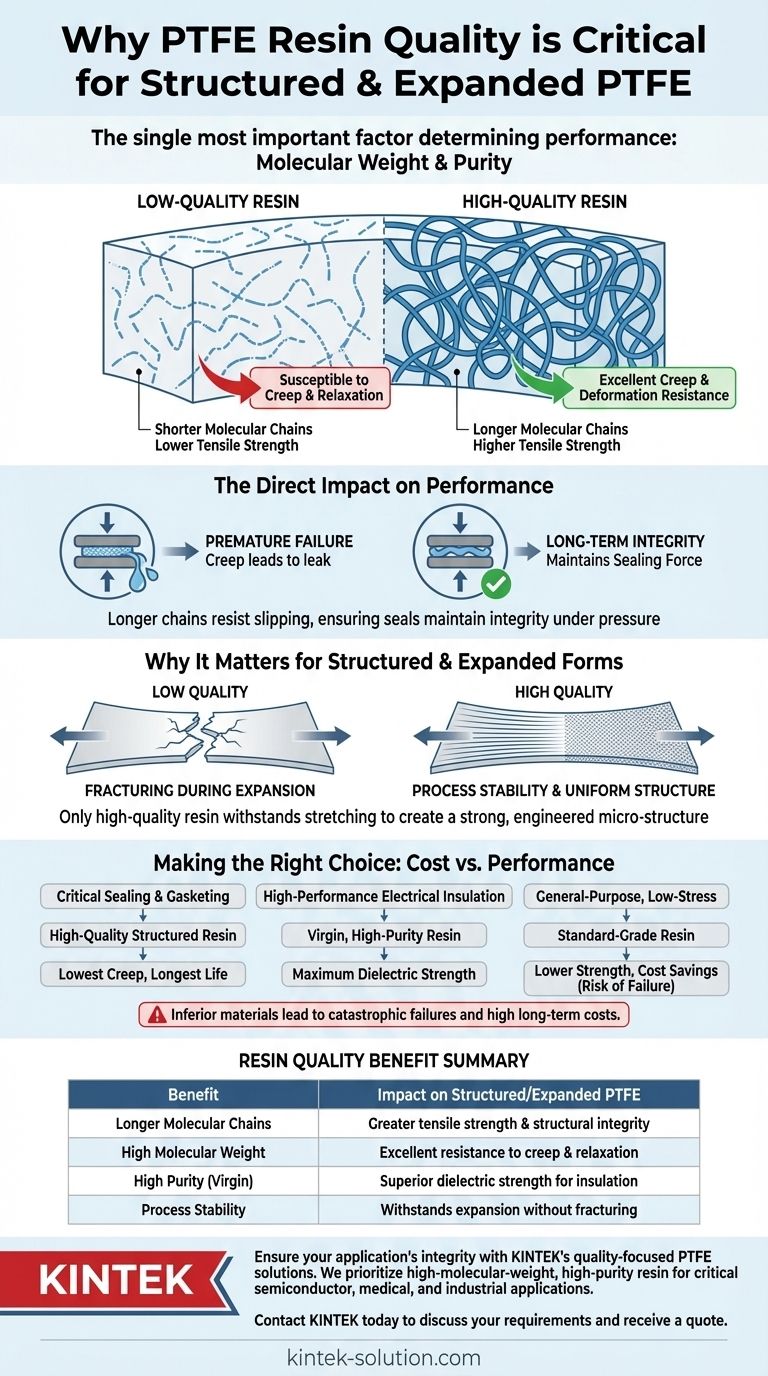

To be clear, the quality of the PTFE resin is the single most important factor determining the performance of structured and expanded PTFE. Higher-quality resins possess longer molecular chains, which directly translates to greater material strength. This inherent strength is critical for resisting creep and relaxation, ensuring the material maintains its shape and sealing force under pressure over time.

The core issue is one of structural integrity. Structured and expanded PTFE are engineered materials whose advanced properties are unlocked during manufacturing, but this potential can only be realized if the foundational resin has the molecular length and purity needed to resist long-term physical deformation in demanding applications.

The Molecular Link Between Resin and Performance

The difference between a high-performance seal and a premature failure begins at the molecular level of the raw PTFE resin.

What Defines High-Quality Resin?

High-quality PTFE resin is characterized by its high molecular weight, which means its individual polymer chains are significantly longer.

These long, entangled chains act like reinforcement within the material, providing a robust internal structure.

The Direct Impact on Mechanical Strength

Longer molecular chains create a material with much higher tensile strength. They are more difficult to pull apart and are better at resisting deformation.

This is the foundation for all the desirable properties that follow, from creep resistance to durability.

Why This Matters for Structured & Expanded Forms

Structured and expanded PTFE are created through processes that stretch and manipulate the material, creating a specific micro-structure.

Only a high-quality resin with long molecular chains can withstand this process without fracturing and can hold its new, stronger form. The process essentially aligns these long chains to maximize their inherent strength.

Preventing Failure in Critical Sealing Applications

In industries from chemical processing to aerospace, material failure is not an option. The choice of resin quality directly impacts operational safety and reliability.

The Problem of Creep and Relaxation

Creep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stress.

For a gasket or seal, this means it slowly loses its shape and sealing pressure, eventually leading to a leak. Relaxation is the related decrease in stress when the material is held at a constant strain.

How Quality Resin Resists Deformation

The longer, entangled molecules in a high-quality resin resist slipping past one another when a load is applied.

This molecular-level friction is what gives the material its excellent creep resistance, ensuring a seal maintains its integrity over thousands of hours of service.

Ensuring Sealing Integrity

In a flange gasket, for example, the material is compressed to create a seal. A low-quality resin will creep, causing the bolt load to relax and the seal to fail.

A high-quality structured PTFE maintains its form, providing a reliable, long-term, leak-free seal.

Understanding the Trade-offs

Selecting a material is always a balance of factors, but with high-performance PTFE, the consequences of choosing incorrectly can be severe.

The Cost vs. Performance Equation

High-quality PTFE resins are more complex to produce and are therefore more expensive.

However, the cost of a single instance of seal failure—in terms of downtime, safety incidents, or environmental release—far outweighs the initial material savings of choosing a lower-grade product.

The Risk of Inferior Materials

Using a resin not specified for structured or expanded PTFE can lead to catastrophic failure. The material will lack the necessary tensile strength and creep resistance, leading to premature leaks.

This is a common point of failure when generic, unspecified PTFE is substituted in an application that demands a high-performance structured material.

Beyond Mechanical Properties

Resin quality also impacts other critical characteristics. For electrical and insulator applications, virgin PTFE (unfilled) is considered the highest quality due to its purity.

The absence of fillers ensures the highest possible dielectric strength and electrical resistance, a property that would be compromised by lower-purity resins or certain additives.

Making the Right Choice for Your Goal

Your application's demands should dictate your material specification.

- If your primary focus is critical sealing and gasketing: Demand a high-quality resin specifically designed for structured PTFE to ensure the lowest possible creep and longest service life.

- If your primary focus is high-performance electrical insulation: Specify virgin, high-purity PTFE resin to achieve the maximum dielectric strength required for your application.

- If your primary focus is general-purpose, low-stress components: A standard-grade resin may be sufficient, but you must accept the trade-off of significantly lower mechanical strength and stability.

Ultimately, investing in the correct PTFE resin quality is a direct investment in the long-term integrity and safety of your system.

Summary Table:

| High-Quality PTFE Resin Benefit | Impact on Structured/Expanded PTFE |

|---|---|

| Longer Molecular Chains | Greater tensile strength and structural integrity. |

| High Molecular Weight | Excellent resistance to creep and relaxation. |

| High Purity (Virgin) | Superior dielectric strength for electrical insulation. |

| Process Stability | Withstands expansion/stretching without fracturing. |

Ensure your application's integrity with PTFE components built on a foundation of quality.

At KINTEK, we understand that the performance of structured and expanded PTFE seals, liners, and labware starts with the resin. We prioritize high-molecular-weight, high-purity PTFE to deliver the exceptional creep resistance, durability, and sealing force your critical applications in the semiconductor, medical, and industrial sectors demand.

Don't compromise on performance or safety. Let our expertise in custom PTFE fabrication—from prototypes to high-volume orders—provide you with reliable, long-lasting solutions.

Contact KINTEL today to discuss your specific requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications