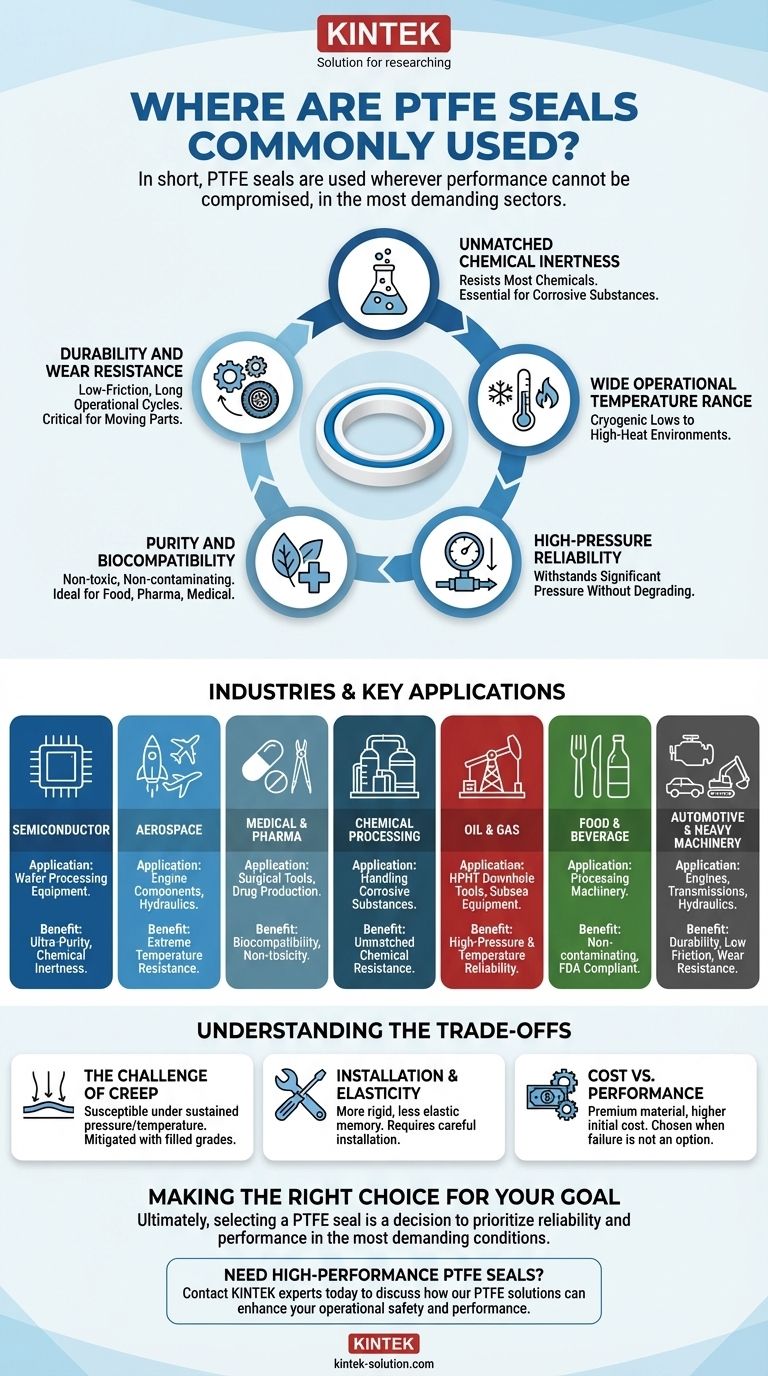

In short, PTFE seals are used wherever performance cannot be compromised. You will find them in the most demanding sectors, including oil and gas, aerospace, chemical processing, food and pharmaceutical production, and semiconductor manufacturing. These industries rely on Polytetrafluoroethylene (PTFE), also known by the brand name Teflon, for its unique ability to withstand conditions that would cause other materials to fail.

The widespread adoption of PTFE seals isn't defined by the industries themselves, but by the material's unique capabilities. Its exceptional resistance to extreme temperatures, harsh chemicals, and high pressures makes it the default choice for critical applications where seal failure is not an option.

Why PTFE is the Material of Choice for Extreme Environments

The value of PTFE seals comes from a specific set of material properties. Understanding these properties explains why they are so prevalent across different demanding fields.

Unmatched Chemical Inertness

PTFE is virtually inert and does not react with most chemicals. This makes it essential for applications involving corrosive substances.

This property is critical in the chemical processing, petrochemical, and pharmaceutical industries, where seals are constantly exposed to aggressive materials.

A Wide Operational Temperature Range

PTFE maintains its integrity and sealing capability across an incredibly broad temperature spectrum, from cryogenic lows to high-heat environments.

This is why it's used in aerospace engine components and hydraulic systems, as well as in oil and gas equipment for both subsea and high-temperature downhole tools.

High-Pressure Reliability

The material can withstand significant pressure without degrading or losing its seal.

This makes it indispensable for high-pressure, high-temperature (HPHT) applications common in the energy sector and for hydraulic systems in heavy construction equipment.

Purity and Biocompatibility

PTFE is non-toxic and does not contaminate the media it contacts.

This characteristic is non-negotiable in food processing, pharmaceutical production, and medical devices like surgical tools and analyzers. It is also vital for the ultra-clean environments required in semiconductor manufacturing.

Durability and Wear Resistance

PTFE provides a low-friction surface that resists wear over long operational cycles, even in harsh conditions.

This durability is crucial for moving parts in automotive engines and transmissions, as well as in the hydraulic cylinders of construction machinery like excavators and loaders.

Understanding the Trade-offs

While PTFE is a high-performance material, no single solution is perfect for every scenario. Acknowledging its specific characteristics is key to using it effectively.

The Challenge of Creep

Under sustained pressure and temperature, pure PTFE can be susceptible to "creep" or "cold flow," where the material slowly deforms over time.

Engineers often mitigate this by using filled PTFE grades, which blend the material with additives like carbon, glass, or stainless steel to enhance its mechanical strength and resistance to creep.

Installation and Elasticity

Compared to standard rubber or elastomer seals, PTFE is a more rigid material.

This means it has less "elastic memory" and may require more careful design and installation procedures to ensure a perfect, leak-free fit from the start.

Cost vs. Performance

PTFE is a premium material, and its cost is higher than that of many common sealing elastomers.

However, it is chosen for applications where the cost of equipment failure—due to downtime, safety risks, or product contamination—is far greater than the initial cost of the seal.

Making the Right Choice for Your Goal

The decision to use a PTFE seal is driven entirely by the operational demands of the application.

- If your primary focus is chemical purity and safety: PTFE's non-toxic and inert properties are ideal for food, medical, and pharmaceutical applications.

- If your primary focus is reliability under extreme pressure and temperature: The robust nature of PTFE makes it essential for oil & gas, energy, and aerospace systems.

- If your primary focus is preventing contamination in clean environments: PTFE is the standard in semiconductor manufacturing due to its inherent purity.

- If your primary focus is durability in mechanical systems: The wear resistance of PTFE is critical for long-lasting performance in automotive and heavy construction machinery.

Ultimately, selecting a PTFE seal is a decision to prioritize reliability and performance in the most demanding conditions.

Summary Table:

| Industry | Key Application | Primary PTFE Benefit |

|---|---|---|

| Semiconductor | Wafer processing equipment | Ultra-purity, chemical inertness |

| Aerospace | Engine components, hydraulics | Extreme temperature resistance |

| Medical & Pharma | Surgical tools, drug production | Biocompatibility, non-toxicity |

| Chemical Processing | Handling corrosive substances | Unmatched chemical resistance |

| Oil & Gas | HPHT downhole tools, subsea equipment | High-pressure & temperature reliability |

| Food & Beverage | Processing machinery | Non-contaminating, FDA compliant |

| Automotive & Heavy Machinery | Engines, transmissions, hydraulics | Durability, low friction, wear resistance |

Need high-performance PTFE seals for your critical application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and custom labware—for the most demanding industries. Whether you require standard parts or custom fabrication from prototypes to high-volume orders, our expertise ensures reliability where failure is not an option.

Contact our experts today to discuss how our PTFE solutions can enhance your operational safety and performance.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the common applications of Teflon bushings in industrial machinery? Solve Friction, Corrosion, and Contamination Problems

- What is the water transmission rate of Teflon encapsulated O-rings? A Guide to Superior Moisture Sealing

- What are the standard bearing assembly configurations for PTFE slide bearings? Choose the Right PTFE Bearing for Your Project

- Why is PTFE more expensive than other sealing materials? Superior Performance Justifies the Cost

- What machining capabilities are available for PTFE/Teflon? Achieve Precision for Complex Parts

- How does the lifespan of PTFE oil seals compare to other types? Achieve 10,000-50,000 Hours of Reliability

- In what applications are PTFE oil seals particularly advantageous? Superior Performance in Extreme Conditions

- What are the main advantages of using PTFE seals? Superior Performance for Demanding Applications