In short, PTFE oil seals are the definitive choice for applications involving high rotational speeds, extreme temperatures, aggressive chemicals, or environments where traditional lubrication is not an option. Their unique material properties allow them to succeed in demanding conditions that would cause standard elastomer seals, like those made from nitrile or Viton, to quickly fail.

The decision to use a PTFE seal is not about finding a marginal upgrade; it's about solving a problem that conventional rubber seals cannot handle. PTFE thrives in the extremes of speed, temperature, and chemical exposure, making it a specialized solution for critical and high-performance equipment.

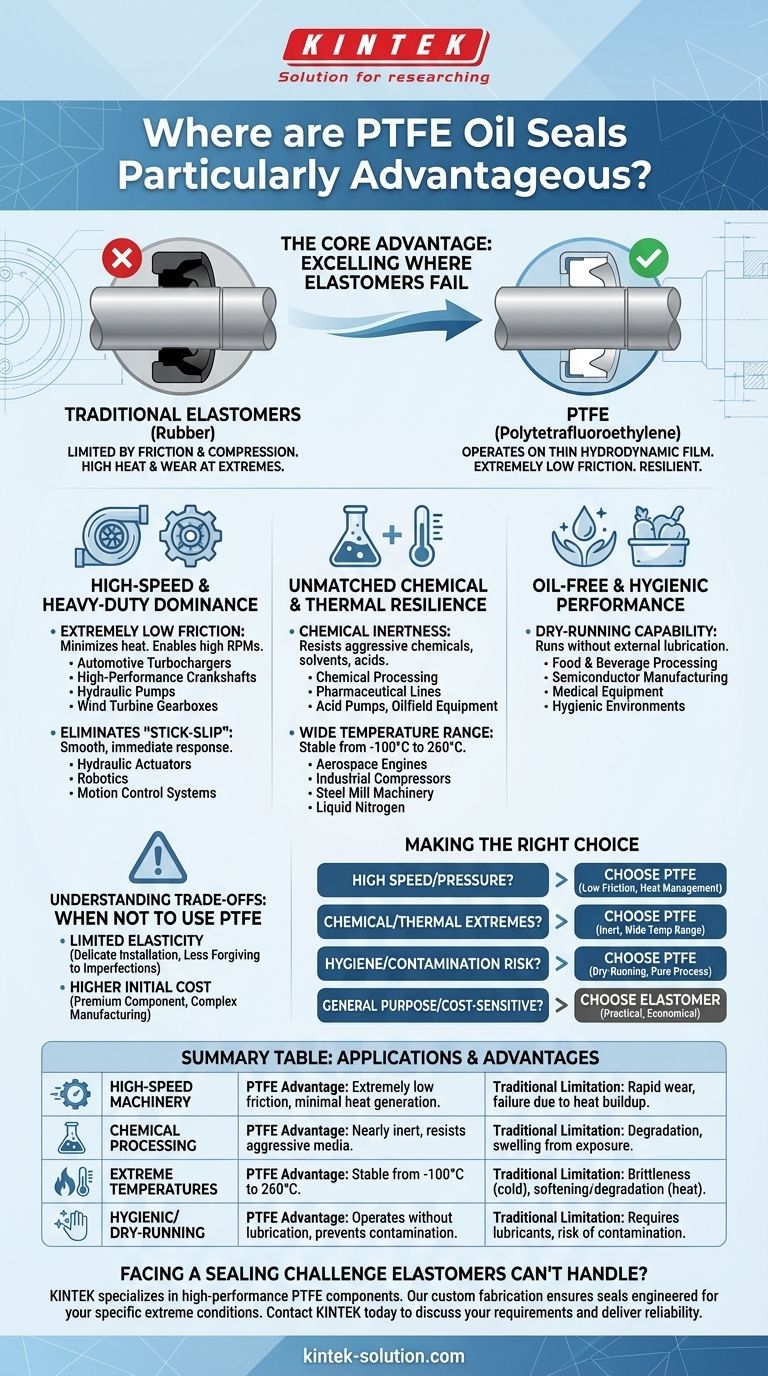

The Core Advantage: Excelling Where Elastomers Fail

Traditional seals are made from elastomers (rubber), which are flexible and create a tight seal through compression. However, this design has inherent limitations.

PTFE (polytetrafluoroethylene) operates on a different principle. As a rigid thermoplastic, it creates a seal with a precisely engineered lip that runs on a thin, hydrodynamic film. This fundamental difference is what allows it to perform in environments far beyond the reach of rubber.

Principle 1: Dominance in High-Speed and Heavy-Duty Applications

The primary advantage of PTFE in dynamic applications is its exceptionally low friction.

Extremely Low Friction

A PTFE seal's coefficient of friction is significantly lower than that of any elastomer. This minimizes heat generation at the point of contact, even at very high surface speeds.

This property makes them essential in equipment like automotive turbochargers, high-performance engine crankshafts, hydraulic pumps, and wind turbine gearboxes, where high RPMs would quickly burn out a traditional rubber seal.

Eliminating "Stick-Slip"

PTFE has virtually no static friction, meaning it does not stick to the shaft when starting from a standstill. This phenomenon, known as "stick-slip," can cause jerky movement and positioning errors in precision equipment.

Because of this, PTFE seals are ideal for hydraulic actuators, robotics, and motion control systems that require smooth, immediate, and predictable response.

Principle 2: Unmatched Chemical and Thermal Resilience

PTFE is renowned for its ability to withstand conditions that would dissolve or degrade other materials.

Chemical Inertness

PTFE is nearly inert, meaning it does not react with most industrial chemicals, solvents, and acids.

This makes it the only viable choice for sealing equipment in chemical processing plants, pharmaceutical production lines, acid pumps, and oilfield equipment where exposure to aggressive media is constant.

Wide Temperature Range

PTFE seals can operate reliably in a vast temperature window, typically from cryogenic lows (-100°C) to extreme highs (260°C).

This thermal stability is critical for applications such as aerospace engines, industrial compressors, steel mill machinery, and equipment handling liquid nitrogen.

Principle 3: Performance in Oil-Free and Hygienic Environments

In many industries, any form of lubricant contamination is unacceptable. PTFE's unique properties allow it to function without external lubrication.

Dry-Running Capability

Because of its low-friction nature, a PTFE lip can run directly on a shaft without oil, a capability known as dry-running.

This is absolutely essential in food and beverage processing, semiconductor manufacturing, and medical equipment, where process purity is paramount and oil contamination would ruin the product.

Understanding the Trade-offs: When Not to Use PTFE

Despite its advantages, PTFE is not a universal solution. Its rigidity creates specific limitations.

Limited Elasticity

PTFE is not elastic like rubber. It does not rebound after being stretched, which makes installation more delicate and requires special tools to avoid damaging the seal lip.

It is also less forgiving of shaft imperfections, such as scratches or excessive runout, which can create leak paths that a flexible rubber seal might accommodate.

Higher Initial Cost

PTFE seals are a premium component manufactured through a more complex process than molded rubber seals. Their cost reflects their high-performance capabilities.

For standard, non-demanding applications, a traditional elastomer seal is often the more cost-effective choice.

Making the Right Choice for Your Goal

Selecting the correct seal requires matching the material to the operational demands.

- If your primary focus is high speed or high pressure: Choose PTFE for its low friction and ability to manage heat in applications like performance engines, gearboxes, and hydraulic systems.

- If your primary focus is chemical resistance or temperature extremes: PTFE is the mandatory choice for sealing aggressive media or operating in cryogenic or high-heat environments.

- If your primary focus is hygiene or avoiding contamination: Select PTFE for its dry-running capability, which is essential for food, pharmaceutical, and semiconductor applications.

- If your primary focus is a general-purpose, cost-sensitive application: A standard elastomer seal is likely the more practical and economical solution for moderate speeds, temperatures, and pressures.

Ultimately, specifying a PTFE seal is a strategic decision for environments where performance and reliability under extreme stress are non-negotiable.

Summary Table:

| Application Scenario | Key PTFE Advantage | Traditional Seal Limitation |

|---|---|---|

| High-Speed Machinery (e.g., turbochargers) | Extremely low friction, minimal heat generation | Rapid wear and failure due to heat buildup |

| Chemical Processing | Nearly inert, resists aggressive solvents and acids | Degradation and swelling from chemical exposure |

| Extreme Temperatures | Stable from -100°C to 260°C | Brittleness at low temps, softening/degradation at high temps |

| Hygienic/Dry-Running (e.g., food, pharma) | Operates without lubrication, prevents contamination | Requires lubricants, risk of product contamination |

Facing a sealing challenge that standard elastomers can't handle?

KINTEK specializes in manufacturing high-performance, precision PTFE components—including seals, liners, and labware—for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services, from prototypes to high-volume orders, ensure you get a seal engineered to thrive in your specific extreme conditions.

Contact KINTEK today to discuss your application requirements and let our expertise in PTFE solutions deliver the reliability and performance your equipment demands.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE rotary seals over traditional rubber seals? Superior Performance in Extreme Conditions

- What makes PTFE stand out among materials used in sealing technology? Unmatched Chemical & Thermal Resistance

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the key properties of PTFE that make it suitable for sealing applications? | High-Performance Seals for Extreme Conditions