At its core, Polytetrafluoroethylene (PTFE) is more expensive because its unique combination of superior properties—including extreme chemical resistance, wide temperature tolerance, and very low friction—is difficult and costly to replicate. The high demand for these high-performance characteristics in critical industries justifies its premium price point.

The cost of PTFE isn't just about the material itself; it's a reflection of its value as a long-term solution. In demanding applications, paying more upfront for PTFE often prevents the much higher costs associated with system failure, downtime, and frequent replacement.

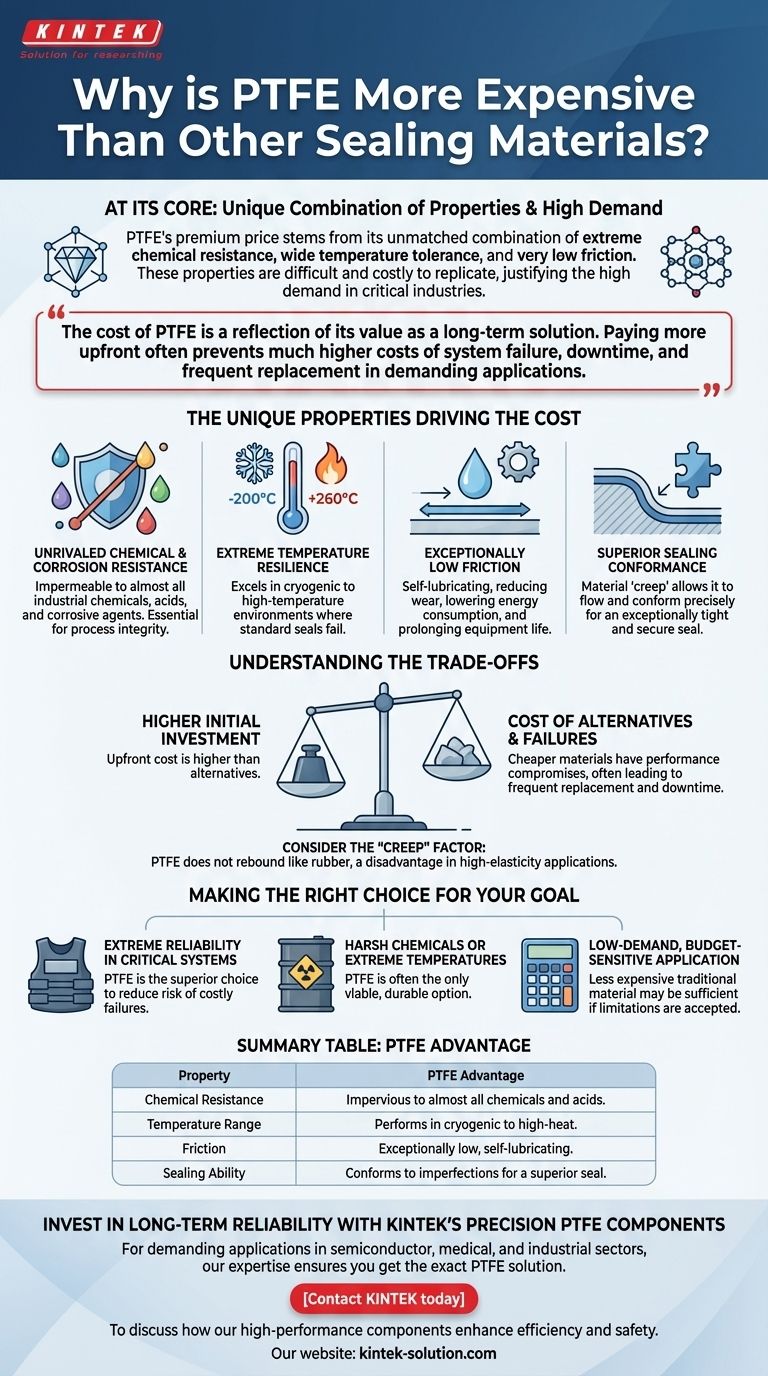

The Unique Properties Driving the Cost

The premium price of PTFE is a direct result of a set of performance characteristics that are unmatched by most other sealing materials. These properties ensure reliability where other materials would fail.

Unrivaled Chemical and Corrosion Resistance

PTFE is virtually impermeable to almost all industrial chemicals, acids, and corrosive agents. This makes it one of the most corrosion-resistant materials available.

This inertness is essential in chemical processing, manufacturing, and aerospace applications where seal integrity in the presence of aggressive substances is non-negotiable.

Extreme Temperature Resilience

Standard elastomer O-rings and gaskets have a limited operating temperature range. PTFE, however, excels in both cryogenic and high-temperature environments.

It maintains its integrity in applications ranging from deep-freeze conditions to high-heat ovens and combustion processes, environments where typical seals would become brittle or degrade completely.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This self-lubricating property is critical for dynamic seals.

This ease of movement reduces wear on moving parts, lowers energy consumption, and significantly prolongs the durability and service life of both the seal and the equipment it protects.

Superior Sealing Conformance

A key property of PTFE is its lack of "memory," which results in material creep. While this can be a drawback elsewhere, it is a significant advantage in sealing.

This allows the material to flow and conform precisely to the imperfections of a mating surface, creating an exceptionally tight and secure seal that other, more resilient materials cannot achieve.

Understanding the Trade-offs

While PTFE offers superior performance, its cost and specific mechanical properties create a clear set of trade-offs that must be considered.

The Higher Initial Investment

The most obvious trade-off is the upfront cost. For non-critical applications with minimal exposure to chemicals or extreme temperatures, a less expensive elastomer may be a more practical financial choice.

The Cost of Alternatives

While cheaper materials exist, they always involve a performance compromise. Finding a single alternative that matches PTFE's full range of characteristics is often impossible, and combining materials to do so can be even more costly and complex.

The "Creep" Factor

The same material creep that creates an excellent seal means PTFE does not rebound or return to its original shape like rubber. In applications that require high elasticity and repeated compression cycles, this lack of memory can be a significant disadvantage.

Making the Right Choice for Your Goal

Selecting a sealing material should be based on the demands of the application and the true long-term cost, not just the initial purchase price.

- If your primary focus is extreme reliability in critical systems: PTFE is the superior choice, as its longevity and performance reduce the risk of costly failures.

- If your application involves harsh chemicals or extreme temperatures: PTFE is often the only viable option that can withstand the conditions without rapid degradation.

- If your primary focus is a low-demand, budget-sensitive application: A less expensive traditional material may be sufficient, provided you understand and accept its performance limitations.

Ultimately, choosing PTFE is an investment in stability, safety, and long-term operational efficiency.

Summary Table:

| Property | PTFE Advantage |

|---|---|

| Chemical Resistance | Impervious to almost all industrial chemicals and acids. |

| Temperature Range | Performs in cryogenic to high-heat environments. |

| Friction | Exceptionally low, self-lubricating coefficient. |

| Sealing Ability | Conforms to surface imperfections for a superior seal. |

Invest in the long-term reliability of your critical systems with KINTEK's precision PTFE components.

For demanding applications in the semiconductor, medical, laboratory, and industrial sectors, the superior performance of PTFE seals, liners, and labware prevents costly downtime and failures. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact PTFE solution your operation requires.

Contact KINTEK today to discuss how our high-performance PTFE components can enhance your operational efficiency and safety.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability