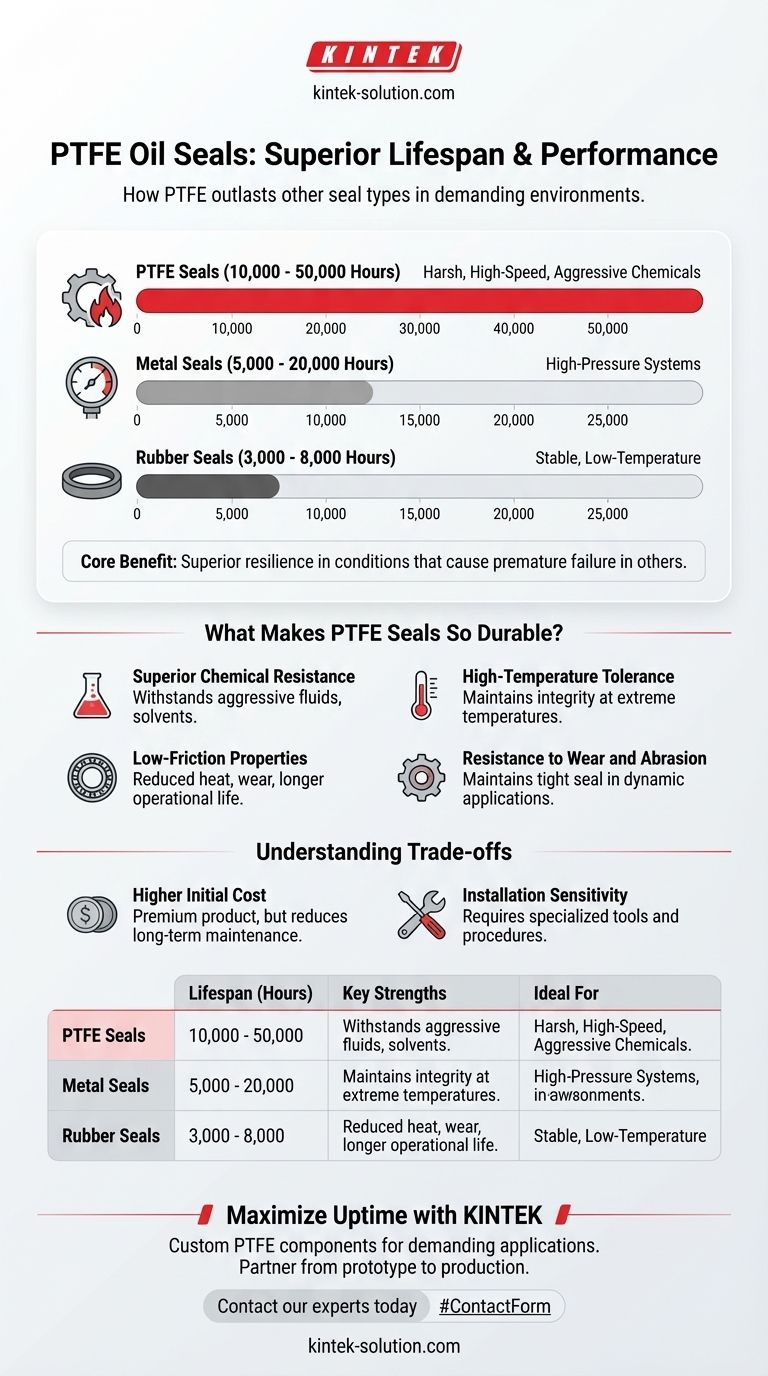

In terms of operational lifespan, Polytetrafluoroethylene (PTFE) oil seals significantly outperform their common counterparts. A high-quality PTFE seal can be expected to last between 10,000 and 50,000 hours, whereas standard rubber seals typically last 3,000 to 8,000 hours, and metal seals fall in the 5,000 to 20,000-hour range. This dramatic difference is most pronounced in demanding operational environments.

The core reason for selecting a PTFE seal is not just its longer lifespan in hours, but its superior resilience in conditions—high temperatures, aggressive chemicals, and high-speed rotation—that would cause other materials to fail prematurely.

What Makes PTFE Seals So Durable?

The extended service life of a PTFE seal is not a coincidence; it is a direct result of the inherent chemical properties of Polytetrafluoroethylene. Understanding these properties is key to knowing when to specify this material.

Superior Chemical Resistance

PTFE is a chemically inert material. This means it can withstand exposure to a wide range of corrosive fluids, solvents, and aggressive chemicals without degrading, which is a common failure point for many rubber compounds.

High-Temperature Tolerance

PTFE seals maintain their structural integrity and sealing capability at temperatures that would cause rubber seals to harden, crack, or lose their elasticity. This makes them essential for high-performance engines, transmissions, and industrial machinery.

Low-Friction Properties

One of PTFE's defining characteristics is its extremely low coefficient of friction. In rotating applications, like those using PTFE lip seals, this translates to less heat generation, reduced wear on the shaft, and a longer operational life for both the seal and the equipment.

Resistance to Wear and Abrasion

The material composition of PTFE provides excellent wear resistance. This ensures it can maintain a tight seal over tens of thousands of hours, even in dynamic applications with constant movement, such as with PTFE piston seals in hydraulic cylinders.

Comparing Lifespan Across Seal Materials

While raw numbers provide a clear picture, the context of the operating environment is what truly matters when evaluating these figures.

PTFE Seals (10,000–50,000 hours)

This wide range reflects its use in everything from moderately demanding industrial gearboxes to extreme aerospace applications. The higher end of the scale is achieved in optimized conditions where temperature and chemical exposure are managed.

Metal Seals (5,000–20,000 hours)

Metal seals offer a step up in durability from rubber, particularly in high-pressure situations. However, they lack the chemical resistance and low-friction benefits of PTFE, limiting their lifespan in certain applications.

Standard Rubber Seals (3,000–8,000 hours)

Nitrile (NBR) or Viton (FKM) rubber seals are excellent for general-purpose use. They are cost-effective and reliable in stable, low-temperature environments but degrade quickly when exposed to harsh chemicals or high heat.

Understanding the Trade-offs

No material is a universal solution. Choosing a PTFE seal involves considering its unique characteristics and potential challenges.

Higher Initial Cost

PTFE seals are a premium product. Their manufacturing process is more complex, leading to a higher upfront cost compared to standard rubber seals. This cost must be weighed against the reduced maintenance and downtime over the equipment's life.

Installation Sensitivity

PTFE lip seals are typically more rigid than their rubber counterparts. They are less forgiving of installation errors and often require specialized tools or procedures to prevent damage to the sealing lip, which could compromise performance.

Application Suitability

For simple, static applications in a controlled environment with low temperatures and non-aggressive fluids, the extended lifespan of a PTFE seal may be unnecessary. In such cases, a more cost-effective rubber seal is often the more practical choice.

Making the Right Choice for Your Application

Selecting the correct seal material is a critical engineering decision that directly impacts reliability and long-term operating costs.

- If your primary focus is maximum reliability in harsh environments: A PTFE seal is the definitive choice for its unmatched resistance to heat, chemicals, and wear.

- If your primary focus is general-purpose sealing with a tight budget: A standard rubber seal provides reliable performance in non-demanding conditions and is the most cost-effective option.

- If your primary focus is durability in high-pressure systems without extreme temperatures: A metal seal can offer a good balance of longevity and performance.

Ultimately, choosing the right seal is about matching the material's capabilities to the precise demands of the application.

Summary Table:

| Material | Typical Lifespan (Hours) | Key Strengths | Ideal For |

|---|---|---|---|

| PTFE Seals | 10,000 - 50,000 | Superior chemical resistance, high-temperature tolerance, low friction | Harsh environments, high-speed rotation, aggressive chemicals |

| Metal Seals | 5,000 - 20,000 | High-pressure durability | High-pressure systems without extreme temperatures |

| Rubber Seals | 3,000 - 8,000 | Cost-effective, reliable for general use | Stable, low-temperature, non-aggressive environments |

Maximize your equipment's uptime and performance with KINTEK's precision PTFE components.

Our custom-fabricated PTFE seals, liners, and labware are engineered to deliver exceptional longevity and reliability in the most demanding semiconductor, medical, laboratory, and industrial applications. We partner with you from prototype to high-volume production to ensure a perfect fit and superior performance.

Ready to solve your toughest sealing challenges? Contact our experts today to discuss your specific requirements and see how our PTFE solutions can extend your equipment's lifespan and reduce maintenance costs.

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are some common PTFE seal types used in industrial applications? Explore Solutions for Every Motion & Environment

- What are the key properties of PTFE that make it suitable for seals? Unlock Reliability in Extreme Conditions

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- How do FEP and PTFE encapsulated O-rings contribute to equipment longevity? Prevent Costly Downtime with Superior Seals

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance