The key to maintaining Teflon gland packing is regular monitoring for leakage and friction, while troubleshooting focuses on methodical adjustments and root cause analysis. Effective maintenance involves correcting leakage with gradual compression adjustments, preventing excessive wear through proper installation, and avoiding material degradation by ensuring chemical compatibility.

The most common failures in Teflon gland packing are not due to the material itself, but to improper installation and a misunderstanding of its function. True success lies in proactive installation and aiming for controlled, minimal leakage rather than reactive over-tightening.

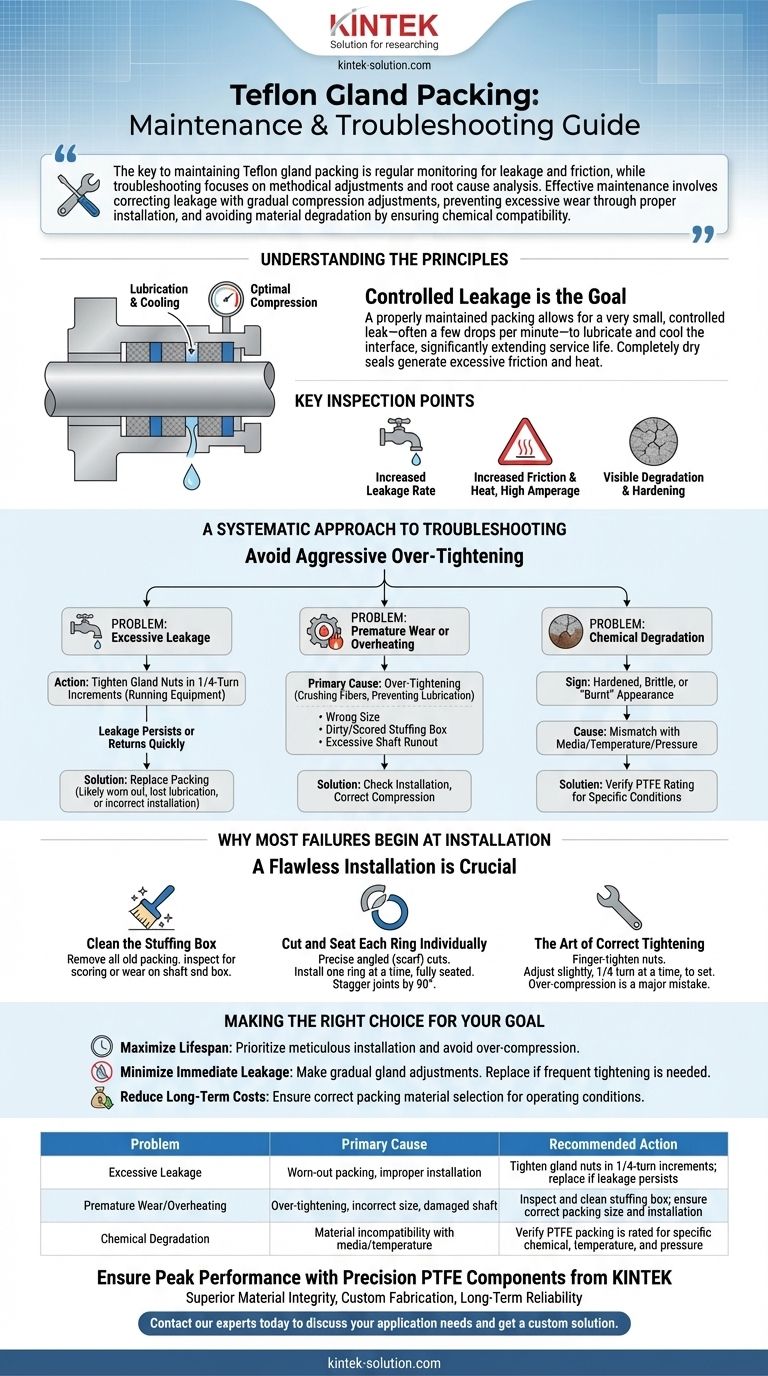

Understanding the Principles of Packing Maintenance

Effective maintenance isn't about eliminating all leaks; it's about managing them. A small amount of leakage is often by design, providing essential lubrication and cooling to the packing and the shaft.

The Goal of Controlled Leakage

Gland packing functions by creating a seal through compression. However, a completely dry seal generates excessive friction and heat, which can damage both the packing and the equipment shaft.

A properly maintained packing allows for a very small, controlled leak—often a few drops per minute—to lubricate and cool the interface, significantly extending the service life of the system.

Key Inspection Points

Regular inspection is the cornerstone of proactive maintenance. Look for clear signs that adjustment or replacement is needed.

These signs include a noticeable increase in leakage rate, evidence of increased friction (such as higher motor amperage draw), or visible degradation and hardening of the packing material.

A Systematic Approach to Troubleshooting

When problems arise, resist the immediate urge to aggressively tighten the gland follower. This often worsens the underlying issue. Instead, diagnose the problem systematically.

Problem: Excessive Leakage

This is the most common issue. The first step is to tighten the gland nuts in small, even increments—typically one-quarter turn at a time—while the equipment is running.

If leakage persists or quickly returns, the packing is likely worn out, has lost its lubrication, or was installed incorrectly. At this point, replacement is the correct solution.

Problem: Premature Wear or Overheating

Excessive wear is almost always a symptom of improper installation or operation. Over-tightening is the primary culprit, as it crushes the packing fibers and prevents necessary lubrication.

Other causes include using the wrong size packing, a dirty or scored stuffing box, or excessive shaft runout (wobble), which puts uneven pressure on the packing.

Problem: Chemical Degradation

If the packing appears hardened, brittle, or "burnt," it signifies a mismatch between the material and the operating environment.

While Teflon (PTFE) has excellent chemical resistance, it has temperature and pressure limitations. Ensure the selected packing is rated for the specific chemical media, temperature, and pressure of your application.

Why Most Failures Begin at Installation

A flawless installation is the single most important factor in the long-term performance of gland packing. Cutting corners here will inevitably lead to premature failure and increased downtime.

Clean the Stuffing Box Thoroughly

Before installing new rings, you must remove all of the old packing. Use proper packing extraction tools and inspect the stuffing box and shaft for scoring or wear. A damaged shaft will quickly destroy new packing.

Cut and Seat Each Ring Individually

Never wind packing into a coil inside the stuffing box. Each ring must be cut precisely to size with a clean, angled (scarf) cut to ensure a tight seal at the joint.

Install one ring at a time, making sure it is fully seated. Stagger the joints of consecutive rings by 90 degrees to prevent creating a direct leak path.

The Art of Correct Tightening

After installing the rings, tighten the gland follower nuts until they are finger-tight. Then, use a wrench to tighten them slightly more, typically one-quarter turn at a time, to set the packing.

Start the equipment and allow it to run for a short period. Adjust the gland follower as needed to achieve the target controlled leakage rate. Over-compression at this stage is the most common and damaging mistake.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your operational priorities. Understanding the trade-offs between component life, leakage control, and cost will guide your approach.

- If your primary focus is maximizing equipment lifespan: Prioritize meticulous installation, especially shaft inspection and avoiding over-compression, to prevent costly damage.

- If your primary focus is minimizing immediate leakage: Make gradual gland adjustments, but if frequent tightening is required, schedule a replacement to address the root cause.

- If your primary focus is reducing long-term maintenance costs: Ensure you select the correct packing material for your specific operating conditions (chemical, temperature, pressure) from the outset.

Ultimately, treating gland packing maintenance as a precision skill, not a brute-force task, is the key to reliable and efficient equipment operation.

Summary Table:

| Problem | Primary Cause | Recommended Action |

|---|---|---|

| Excessive Leakage | Worn-out packing, improper installation | Tighten gland nuts in 1/4-turn increments; replace if leakage persists |

| Premature Wear/Overheating | Over-tightening, incorrect size, damaged shaft | Inspect and clean stuffing box; ensure correct packing size and installation |

| Chemical Degradation | Material incompatibility with media/temperature | Verify PTFE packing is rated for specific chemical, temperature, and pressure |

Ensure Peak Performance with Precision PTFE Components from KINTEK

Proper maintenance starts with high-quality, correctly specified parts. KINTEK specializes in manufacturing precision PTFE components—including seals, gland packing, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We deliver:

- Superior Material Integrity: Our PTFE components offer excellent chemical resistance and durability.

- Custom Fabrication: From prototypes to high-volume orders, we tailor solutions to your exact operational requirements.

- Long-Term Reliability: Precision manufacturing reduces wear and downtime, protecting your critical equipment.

Don't let packing failures disrupt your operations. Contact our experts today to discuss your application needs and get a custom solution that ensures reliability and efficiency.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key applications of PTFE plugs? Seal and Protect in Demanding Environments

- What are the features of Polytetrafluoroethylene (PTFE) with Mineral Fill? Achieve Superior Durability in Demanding Applications

- What is the primary material distinction between PTFE washers and rubber washers? Choose the Right Washer for Your Application

- Why is the quality of PTFE resin important for structured and expanded PTFE? Ensure Long-Term Sealing Integrity

- What nominal pressure ratings are available for PTFE gaskets? Understand the Limits of Pure PTFE

- What makes Teflon suitable for electrical applications? Unmatched Insulation for Extreme Conditions

- What industries commonly use PTFE lined dual plate check valves? Essential for Corrosive & High-Purity Applications

- What industries can benefit from PTFE-free bushings? Automotive, Aerospace, and Heavy Machinery Solutions