In short, industries that handle corrosive or high-purity fluids rely on PTFE lined dual plate check valves. The most common sectors include chemical processing, petrochemicals, pharmaceuticals, water treatment, and food processing, where preventing contamination and equipment degradation is critical.

The decision to use a PTFE lined dual plate check valve is not about the industry itself, but about the nature of the fluid being managed. These valves are the standard choice wherever aggressive media must be controlled without compromising the integrity of the system or the purity of the product.

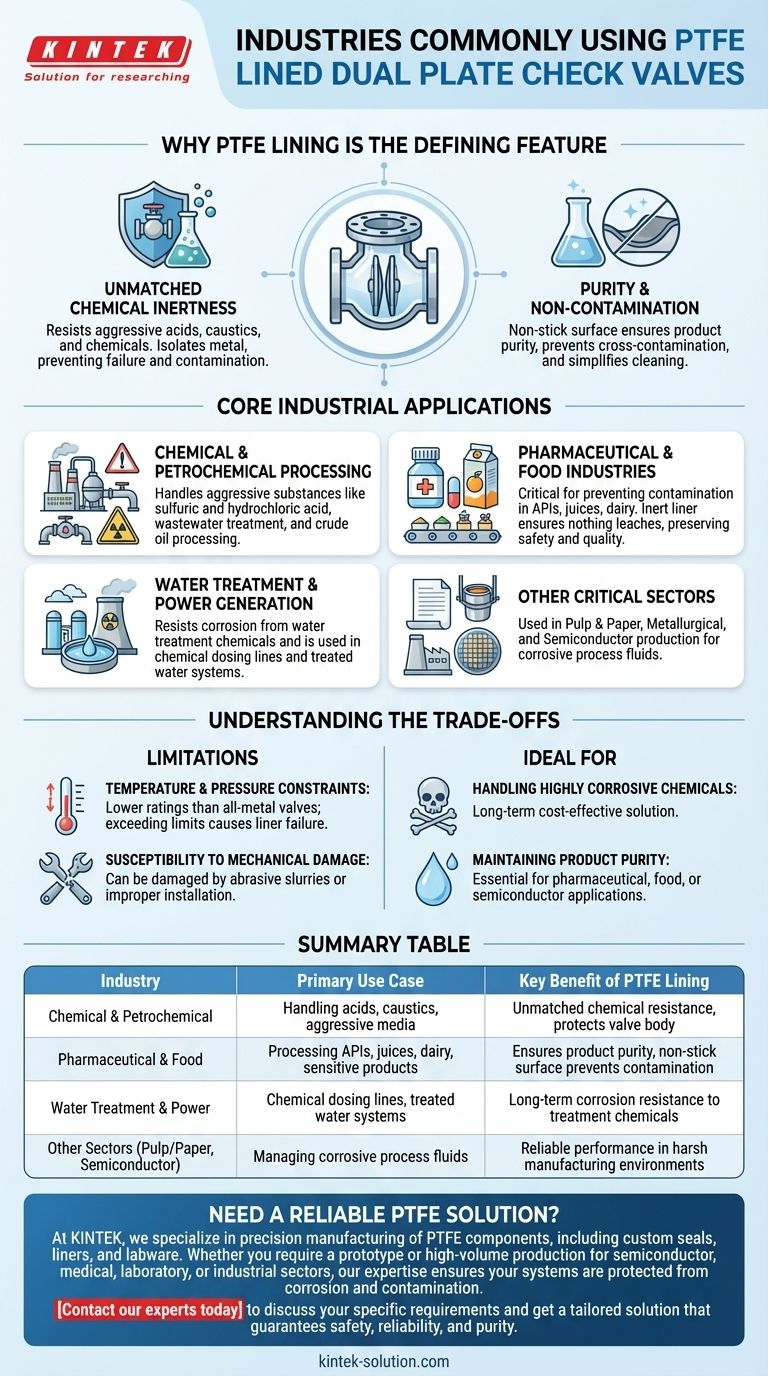

Why PTFE Lining is the Defining Feature

PTFE (Polytetrafluoroethylene) is a high-performance fluoropolymer, and its properties are the reason these valves are specified in demanding environments.

Unmatched Chemical Inertness

The primary benefit of PTFE is its exceptional resistance to chemical attack. It is virtually inert to most industrial chemicals, acids, and caustic solutions.

This means the valve's metal body is completely isolated from the corrosive fluid, preventing both valve failure and contamination of the media.

Purity and Non-Contamination

PTFE has a non-stick, low-friction surface. This is critical in industries like pharmaceuticals and food processing.

This property prevents material from adhering to the valve's internal surfaces, which simplifies cleaning, ensures product purity, and stops cross-contamination between batches.

The Role of the Dual Plate Check Valve

The dual plate design provides a simple, effective function: preventing backflow. When this mechanical design is combined with a PTFE liner, you get a valve that not only performs its function reliably but also withstands the harshest process conditions.

Core Industrial Applications

While many industries use these valves, their application is most critical in sectors where fluid properties are extreme.

Chemical and Petrochemical Processing

This is the largest area of application. These valves are used to handle aggressive substances like sulfuric acid, hydrochloric acid, and other corrosive chemicals found in manufacturing, wastewater treatment, and crude oil processing.

Pharmaceutical and Food Industries

In these sectors, preventing contamination is paramount. PTFE lined valves are specified for handling everything from active pharmaceutical ingredients (APIs) to juices and dairy products.

The inert nature of the liner ensures that nothing leaches into the product, preserving its safety and quality.

Water Treatment and Power Generation

Municipal and industrial water treatment facilities often use a variety of chemicals for purification. PTFE lined valves resist corrosion from these chemicals over the long term.

In power plants, they are used in systems that handle treated water or chemical dosing lines.

Other Critical Sectors

You will also find these valves specified in pulp and paper manufacturing, metallurgical industries, and semiconductor production. In each case, they are chosen to handle specific corrosive fluids integral to the manufacturing process.

Understanding the Trade-offs

While highly effective, PTFE lined valves are not a universal solution. It's important to understand their limitations.

Temperature and Pressure Constraints

PTFE has specific temperature and pressure ratings that are generally lower than those of all-metal valves. Exceeding these limits can cause the liner to fail.

Engineers must always verify that the process conditions fall within the manufacturer's specified operating range for the valve.

Susceptibility to Mechanical Damage

The PTFE liner, while durable, can be damaged by abrasive slurries or improper installation (e.g., over-tightening flanges). Care must be taken during specification and handling to ensure the liner's integrity is not compromised.

Making the Right Choice for Your Goal

Selecting the right valve depends entirely on the specific demands of your application.

- If your primary focus is handling highly corrosive chemicals: A PTFE lined valve is almost always the correct and most cost-effective long-term solution.

- If your primary focus is maintaining product purity: The non-stick, inert surface of PTFE is essential for preventing contamination in pharmaceutical, food, or semiconductor applications.

- If you are dealing with high temperatures or abrasive solids: You may need to consider a different valve type or a specialty liner designed specifically for those conditions.

Ultimately, specifying a PTFE lined dual plate check valve is a strategic decision to ensure safety, reliability, and purity in demanding fluid-handling systems.

Summary Table:

| Industry | Primary Use Case | Key Benefit of PTFE Lining |

|---|---|---|

| Chemical & Petrochemical | Handling acids, caustics, and aggressive media | Unmatched chemical resistance, protects valve body |

| Pharmaceutical & Food | Processing APIs, juices, dairy, and sensitive products | Ensures product purity, non-stick surface prevents contamination |

| Water Treatment & Power | Chemical dosing lines and treated water systems | Long-term corrosion resistance to treatment chemicals |

| Other Sectors (Pulp/Paper, Semiconductor) | Managing corrosive process fluids | Reliable performance in harsh manufacturing environments |

Need a reliable PTFE solution for your corrosive or high-purity application?

At KINTEK, we specialize in precision manufacturing of PTFE components, including custom seals, liners, and labware. Whether you require a prototype or high-volume production for the semiconductor, medical, laboratory, or industrial sectors, our expertise ensures your systems are protected from corrosion and contamination.

Contact our experts today to discuss your specific requirements and get a tailored solution that guarantees safety, reliability, and purity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications