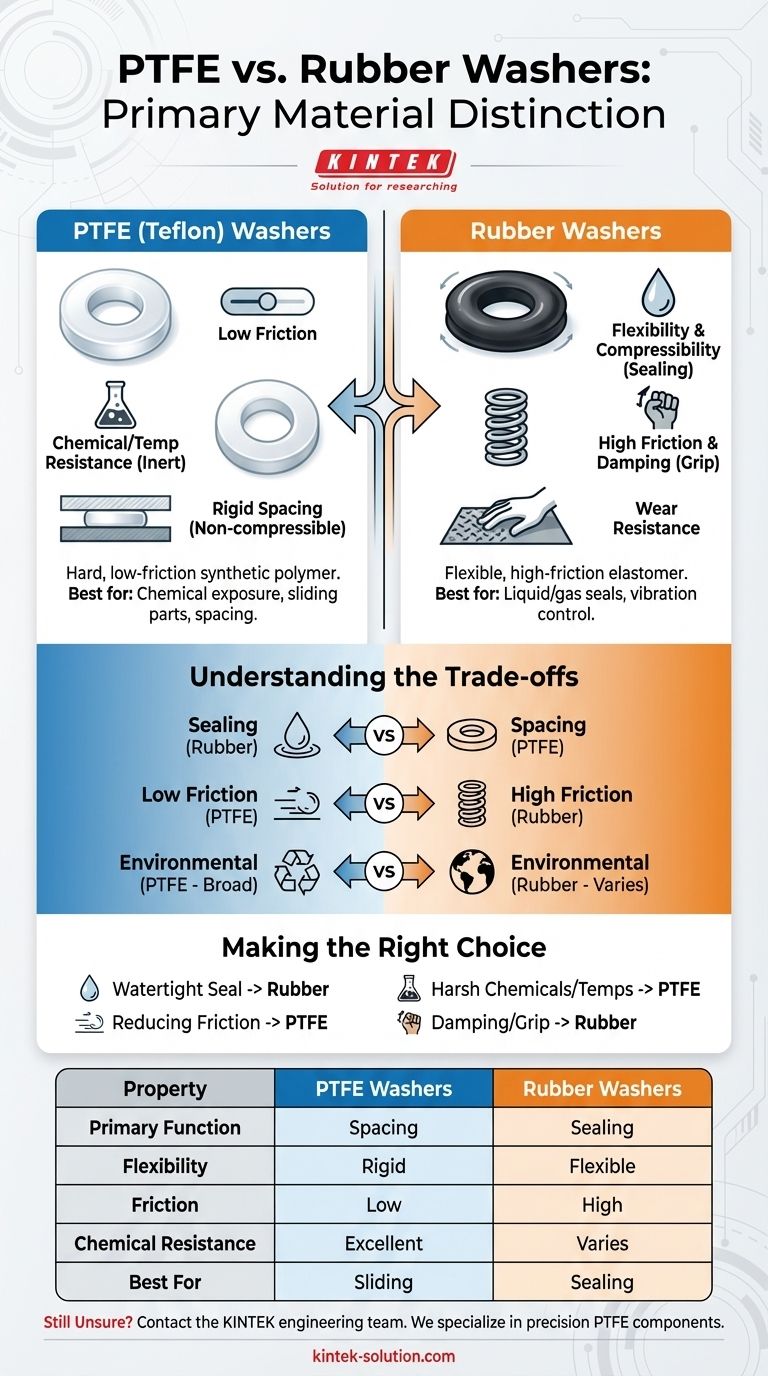

The fundamental difference lies in their core material composition and resulting physical properties. PTFE washers are made from a hard, low-friction synthetic polymer known as Teflon, prized for its chemical inertness. In contrast, rubber washers are made from flexible, high-friction elastomers designed to compress and create seals.

Choosing between PTFE and rubber isn't about which is 'better,' but about aligning the material's core properties—PTFE's slickness and resistance versus rubber's flexibility and sealing ability—with your specific engineering goal.

The Defining Properties of PTFE (Teflon) Washers

Polytetrafluoroethylene (PTFE) is a fluoropolymer with a unique set of characteristics that make it ideal for specific mechanical and chemical applications. It functions primarily as a high-performance plastic, not a soft sealant.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This makes it extremely "slippery," preventing parts from seizing or galling under load.

Chemical and Temperature Resistance

Known by the brand name Teflon, PTFE is almost entirely chemically inert. It can withstand exposure to aggressive chemicals and functions reliably across a very wide temperature range.

Rigidity and Spacing

PTFE washers are relatively hard and resist compression. Their main purpose is often to act as a durable, low-friction spacer between two surfaces rather than to form a compressible seal.

The Defining Properties of Rubber Washers

Rubber washers are made from various elastomers, including natural rubber, silicone, and other synthetic compounds. Their primary value comes from their flexibility and resilience.

Flexibility and Compressibility

The defining trait of rubber is its ability to deform under pressure and then return to its original shape. This allows it to fill microscopic gaps and create a tight, effective seal against liquids or gases.

High Friction and Vibration Damping

Unlike PTFE, rubber has a high coefficient of friction. This property helps it grip surfaces, prevent loosening due to vibration, and absorb mechanical shocks.

Wear and Abrasion Resistance

Many rubber compounds are formulated for excellent durability and resistance to physical wear. This makes them suitable for dynamic applications where they might be subject to rubbing or abrasion while maintaining a seal.

Understanding the Trade-offs

The choice between these two materials comes down to a clear conflict of properties. What makes one material strong for a particular job makes the other entirely unsuitable.

Sealing vs. Spacing

Rubber excels at creating a positive, compressive seal. PTFE excels at providing a low-friction, chemically resistant spacer. Using PTFE where a compressible seal is needed will likely result in a leak.

Low Friction vs. High Friction

PTFE is the clear choice for assemblies with rotating or sliding parts where minimizing friction is critical. Rubber, with its high-friction surface, is designed to stay in place and would create significant drag in such an application.

Environmental Demands

While PTFE offers broad resistance to nearly all chemicals and temperatures, the performance of a rubber washer depends heavily on its specific compound. A standard rubber washer may degrade quickly when exposed to certain oils or solvents, whereas a specialized synthetic rubber might not.

Making the Right Choice for Your Application

Your decision depends entirely on the primary function the washer must perform in your design.

- If your primary focus is creating a watertight or airtight seal: Choose a rubber washer for its superior compressibility and flexibility.

- If your primary focus is reducing friction between moving parts: Choose a PTFE washer for its exceptionally low coefficient of friction.

- If your primary focus is withstanding harsh chemicals or extreme temperatures: Choose a PTFE washer, as it is largely inert and stable.

- If your primary focus is damping vibration or preventing slippage: Choose a rubber washer for its ability to absorb energy and provide grip.

By matching the material's intrinsic nature to your functional need, you ensure optimal performance and reliability in your assembly.

Summary Table:

| Property | PTFE Washers | Rubber Washers |

|---|---|---|

| Primary Function | Spacing, Low Friction | Sealing, Vibration Damping |

| Flexibility | Rigid, Hard | Flexible, Compressible |

| Friction | Exceptionally Low | High |

| Chemical Resistance | Excellent (Inert) | Varies by Compound |

| Best For | Chemical exposure, sliding parts | Liquid/gas seals, vibration control |

Still Unsure Which Washer is Right for Your Project?

Choosing the correct material is critical for the performance and longevity of your assembly. The experts at KINTEK can help you navigate these material distinctions to find the perfect solution.

We specialize in the precision manufacturing of PTFE components—including seals, liners, and labware—for demanding industries like semiconductor, medical, and laboratory equipment. Whether you need a custom PTFE washer for extreme chemical resistance or advice on the best elastomer for a high-pressure seal, we provide custom fabrication from prototypes to high-volume orders.

Let us help you ensure optimal performance and reliability. Contact our engineering team today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What type of glass is used in glass-filled PTFE? The Definitive Answer for Superior Performance

- What are important final considerations when machining Teflon? Mastering PTFE for Precision and Safety

- What advantages does PTFE offer in automotive applications? Enhance Vehicle Efficiency and Durability

- What role does PTFE play in the printing and packaging industry? Enhancing Efficiency and Quality

- What types of industries and applications utilize PTFE parts? Discover the Versatility of PTFE

- What are some common applications for Teflon encapsulated O-rings? Sealing Solutions for Demanding Industries

- What makes PTFE extruded rods suitable for bearings and bushings? Discover Low-Friction, Maintenance-Free Performance

- What are the key features of PTFE bearing pads? Essential for Managing Movement in Large Structures