The primary way PTFE slide bearings reduce project time and costs is through their remarkably simple installation process. Unlike conventional mechanical bearings that often require specialized labor, complex alignment, and additional components, PTFE bearings are typically a straightforward two-part system that can be installed quickly, drastically cutting down on labor hours and associated expenses.

The true value of PTFE slide bearings isn't just in the component itself, but in the total installed cost. By simplifying the installation process and eliminating long-term maintenance, they significantly reduce both initial construction budgets and the total cost of ownership over a structure's lifespan.

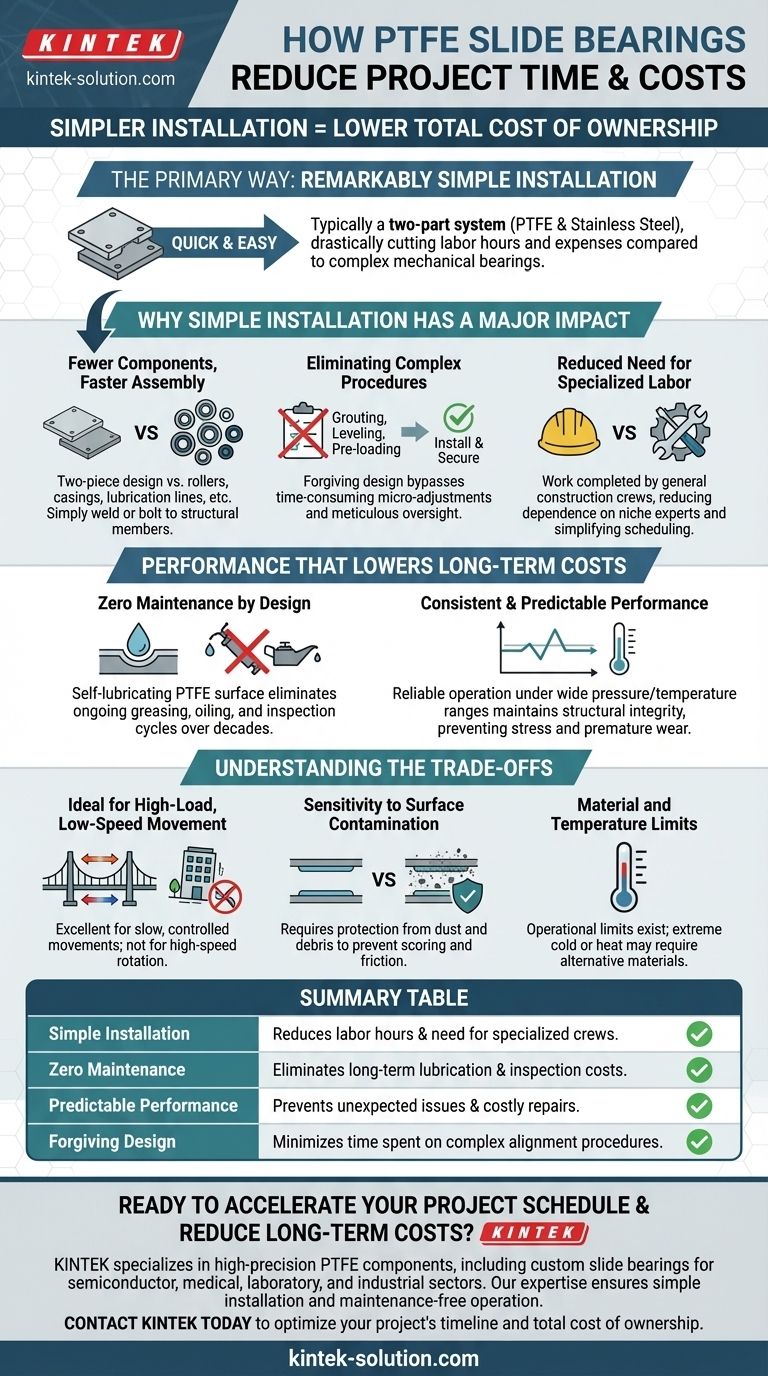

Why Simple Installation Has a Major Impact

The design of a PTFE slide bearing is inherently minimalist, which is the root of its efficiency. Understanding the contrast with traditional methods reveals the full scope of the savings.

Fewer Components, Faster Assembly

A typical PTFE slide bearing consists of two main plates: a polished stainless steel plate and a plate with a bonded layer of PTFE. The installation often involves simply welding or bolting these plates to the corresponding structural members.

This two-piece design contrasts sharply with conventional bearings that may involve rollers, casings, lubrication lines, and complex sealing systems, each adding steps to the assembly process.

Eliminating Complex and Time-Consuming Procedures

Traditional bearing installation can involve grouting, precise leveling, and pre-loading procedures that require significant time and meticulous oversight.

PTFE bearings bypass most of these steps. Their design is more forgiving, reducing the time spent on micro-adjustments and allowing construction to proceed more rapidly.

Reduced Need for Specialized Equipment and Labor

The simplicity of installing PTFE slide bearings means the work can often be completed by general construction crews without the need for highly specialized bearing technicians.

This not only lowers direct labor costs but also simplifies project scheduling, as you are not dependent on the availability of a niche team of experts.

Performance That Lowers Long-Term Costs

The financial benefits of PTFE bearings extend far beyond the initial installation. Their operational characteristics are designed for longevity and reliability, preventing costly future interventions.

Zero Maintenance by Design

The low-friction surface of PTFE is self-lubricating. This completely eliminates the need for the ongoing greasing, oiling, and inspection cycles required by many mechanical bearings, saving significant operational costs over decades.

Consistent and Predictable Performance

As noted in engineering assessments, PTFE performs reliably under a wide range of pressures and temperatures. This consistency is crucial for maintaining the long-term structural integrity of bridges, buildings, and industrial facilities, preventing stress build-up and premature wear.

This reliability means fewer unexpected issues, which translates to lower risk and fewer unplanned maintenance expenses down the line.

Understanding the Trade-offs

While highly effective, PTFE bearings are not a universal solution. An objective assessment requires acknowledging their ideal applications and limitations.

Ideal for High-Load, Low-Speed Movement

PTFE slide bearings excel in applications involving slow, controlled movement under heavy loads. This includes thermal expansion in bridges, structural settling in buildings, and pipe or vessel movements. They are not designed for high-speed rotational applications.

Sensitivity to Surface Contamination

The performance of a PTFE bearing depends on a clean sliding interface. In environments with significant dust, debris, or abrasive particles, the bearing surfaces must be adequately protected or sealed to prevent scoring and increased friction.

Material and Temperature Limits

While robust, PTFE has operational temperature limits. In environments with extreme cold or heat, the material's properties can change, and alternative materials or specialized bearing designs may be required.

Making the Right Choice for Your Project

Selecting the appropriate bearing system requires looking beyond the initial purchase price to the total impact on your project's timeline and lifecycle costs.

- If your primary focus is accelerating the construction schedule: PTFE bearings offer a clear advantage by simplifying installation and reducing dependencies on specialized labor.

- If your primary focus is minimizing long-term operational costs: The zero-maintenance, self-lubricating nature of PTFE bearings makes them an ideal choice for reducing the total cost of ownership.

- If your primary focus is ensuring predictable structural movement: The consistent and reliable performance of PTFE provides the stability needed for critical infrastructure projects.

Ultimately, choosing the right bearing is an investment in both the efficiency of your project's construction and its long-term health and stability.

Summary Table:

| Benefit | Impact on Project |

|---|---|

| Simple Installation | Reduces labor hours and need for specialized crews. |

| Zero Maintenance | Eliminates long-term lubrication and inspection costs. |

| Predictable Performance | Prevents unexpected issues and costly repairs. |

| Forgiving Design | Minimizes time spent on complex alignment procedures. |

Ready to accelerate your project schedule and reduce long-term costs?

KINTEK specializes in manufacturing high-precision PTFE components, including custom slide bearings for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get a bearing solution that delivers on the promise of simple installation and maintenance-free operation, from prototype to high-volume production.

Contact KINTEK today to discuss how our PTFE bearings can optimize your next project's timeline and total cost of ownership.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech