The primary benefit of a Teflon bellow seal's flexibility is its ability to dynamically compensate for imperfections in rotating equipment. This design allows the seal to expand and contract, maintaining constant, leak-proof contact between sealing surfaces despite shaft misalignment, vibration, or thermal changes.

The true value of a Teflon bellow seal isn't just its flexibility, but how that mechanical adaptability combines with Teflon's inherent chemical and thermal resilience. This synergy creates a highly reliable seal that thrives in the imperfect, demanding conditions found in real-world industrial applications.

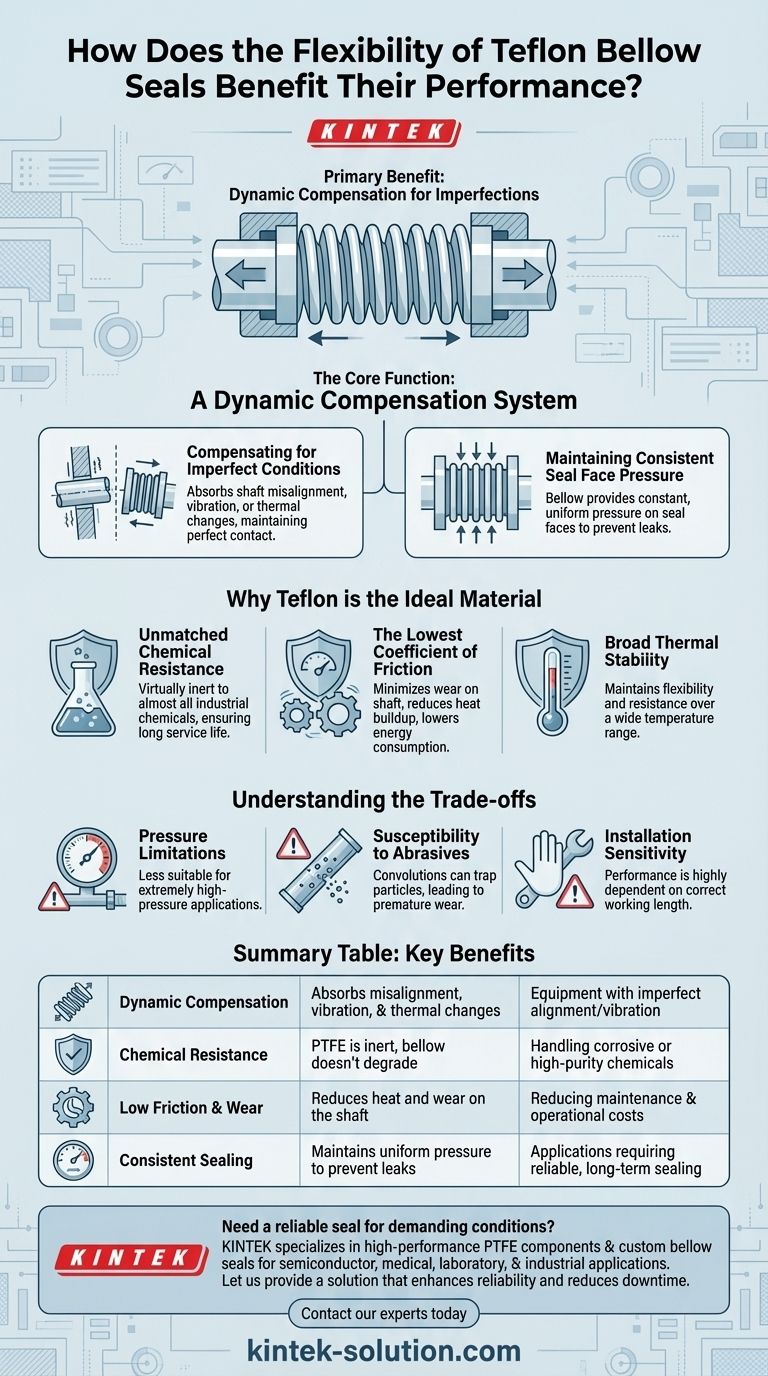

The Core Function: A Dynamic Compensation System

A mechanical seal only works if the two primary sealing faces—one stationary and one rotating—remain in perfect contact. In reality, industrial equipment is rarely perfect. The bellow design is engineered specifically to address these realities.

Compensating for Imperfect Conditions

Rigid seals can fail when faced with common equipment issues like shaft vibration or slight misalignment. The bellow acts as a spring, absorbing these movements and ensuring the seal faces remain squarely in contact.

This adaptability allows the seal to maintain its integrity even under continuous rotation and pressure variations, which are common in pumps and other machinery.

Maintaining Consistent Seal Face Pressure

The "springiness" of the bellow provides a constant, uniform pressure on the seal faces. This is critical for preventing leaks.

Without this consistent force, momentary gaps could form due to shaft movement, leading to seal failure and fluid loss.

Why Teflon is the Ideal Material for This Design

The bellow's mechanical design is only half the story. Using Teflon (PTFE) as the material elevates the seal's performance by adding three critical properties.

Unmatched Chemical Resistance

Teflon is virtually inert to almost all industrial chemicals and corrosive substances. This means the bellow itself will not degrade, swell, or weaken when exposed to aggressive fluids, ensuring a long service life.

The Lowest Coefficient of Friction

Teflon has one of the lowest friction coefficients of any solid material. This is crucial where the seal contacts the rotating shaft.

This low friction reduces heat buildup, minimizes wear on the shaft, and lowers the energy required to run the equipment. It also reduces or eliminates the need for external lubrication.

Broad Thermal Stability

Industrial processes often involve significant temperature fluctuations. Teflon maintains its properties—including flexibility and chemical resistance—over a wide temperature range.

This ensures the seal performs reliably whether the application is very cold or handling hot fluids.

Understanding the Trade-offs

While highly effective, the Teflon bellow design is not a universal solution. Understanding its limitations is key to proper application.

Pressure Limitations

The flexible nature of a bellow can make it less suitable for extremely high-pressure applications compared to more robust, non-bellow seal designs. The pressure limits must always be respected.

Susceptibility to Abrasives

In applications with a high concentration of abrasive solids or slurries, the convolutions of the bellow can sometimes trap particles. This can hinder its flexibility and lead to premature wear.

Installation Sensitivity

The performance of a bellow seal is highly dependent on being installed at the correct working length. Over-compressing or stretching the bellow during installation can drastically reduce its lifespan and effectiveness.

Making the Right Choice for Your Application

The decision to use a Teflon bellow seal should be based on the specific demands of your operating environment.

- If your primary focus is handling corrosive or high-purity chemicals: The chemical inertness of Teflon combined with the bellow's reliable sealing is the ideal choice.

- If your primary focus is reliability in equipment with vibration or minor misalignment: The bellow's ability to absorb movement ensures a continuous seal where more rigid designs would fail.

- If your primary focus is reducing maintenance and operational costs: Teflon's low-friction nature minimizes wear on equipment, extends seal life, and lowers energy consumption.

Ultimately, the flexibility of a Teflon bellow seal transforms it from a simple component into a dynamic solution for reliable sealing in challenging industrial environments.

Summary Table:

| Key Benefit | How Flexibility Helps | Ideal For |

|---|---|---|

| Dynamic Compensation | Absorbs shaft misalignment, vibration, and thermal changes. | Equipment with imperfect alignment or vibration. |

| Chemical Resistance | PTFE material is inert, ensuring the flexible bellow doesn't degrade. | Handling corrosive or high-purity chemicals. |

| Low Friction & Wear | PTFE's low friction reduces heat and wear on the shaft. | Reducing maintenance and operational costs. |

| Consistent Sealing | Maintains uniform pressure on seal faces to prevent leaks. | Applications requiring reliable, long-term sealing. |

Need a reliable seal for demanding conditions?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom bellow seals designed to thrive in the imperfect conditions of semiconductor, medical, laboratory, and industrial applications. Our precision production and custom fabrication—from prototypes to high-volume orders—ensure you get a seal that delivers uncompromising chemical resistance, low friction, and dynamic flexibility.

Let us provide a solution that enhances your equipment's reliability and reduces downtime. Contact our experts today to discuss your specific sealing challenges!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- How does the sealing performance of PTFE gaskets benefit industrial applications? Ensure Leak-Free Reliability in Harsh Environments

- What are the advantages of using Teflon backup rings in chemical processing? Protect Seals from Harsh Chemicals & Extreme Temperatures

- Does modified PTFE (mPTFE) always outperform regular PTFE in seal performance? Make the Right Material Choice

- How is PTFE adapted for semiconductor environments? Leveraging Inertness and Anti-Static Grades for Chip Fab

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- What materials are used in the manufacturing of PTFE ball valves? Optimize for Chemical Resistance & Performance

- What design parameter must be considered when applying wide contact to spring-activated PTFE lip seals? Prevent Bell Mouthing to Avoid Catastrophic Leakage

- What are the uses of Polytetrafluoroethylene (PTFE) with a Proprietary Fill? Enhance Performance for Demanding Applications