In chemical processing, the primary advantages of Teflon backup rings are their unparalleled chemical inertness, wide operational temperature range, and extremely low friction. These properties work in concert to protect primary seals, like O-rings, from failing in the harshest industrial environments, ensuring system integrity and extending service life.

The core function of a Teflon backup ring is not just to provide mechanical support, but to act as a chemical and thermal shield. It ensures the primary O-ring can maintain its seal by preventing physical extrusion caused by high pressure while simultaneously resisting degradation from aggressive media and extreme temperatures.

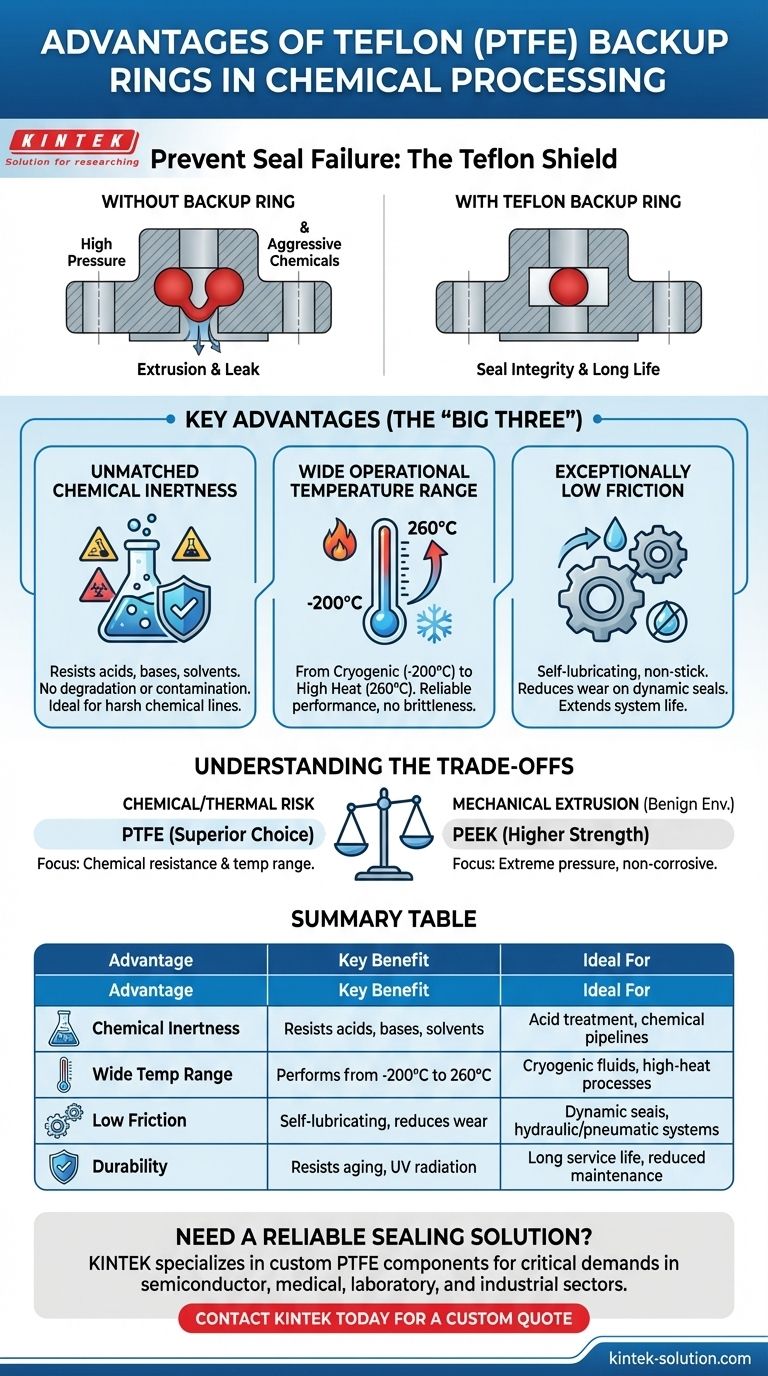

Why Backup Rings Are Essential

Preventing Seal Extrusion

The fundamental purpose of any backup ring is to prevent a softer primary seal, such as a rubber O-ring, from being physically damaged.

Under high pressure, an O-ring can be forced into the small clearance gap between moving parts, a phenomenon known as extrusion. This damages the seal, leading to leaks and eventual system failure.

A backup ring sits in the groove next to the O-ring, on the low-pressure side, physically blocking the clearance gap. This provides a rigid barrier that contains the O-ring, allowing it to function effectively at much higher pressures.

Key Advantages of Teflon (PTFE) in Chemical Applications

Teflon, a brand name for the material PTFE (Polytetrafluoroethylene), offers a unique combination of properties that make it an ideal choice for backup rings in chemical processing equipment.

Unmatched Chemical Inertness

Teflon is renowned for its resistance to a vast spectrum of aggressive chemicals.

It remains stable when exposed to nearly all industrial acids, bases, solvents, and other corrosive media. This ensures the backup ring itself does not degrade, swell, or contaminate the process.

This chemical stability is critical in applications like acid treatment equipment, chemical pipelines, and valves where material integrity is paramount.

Wide Operational Temperature Range

PTFE backup rings perform reliably across an exceptionally broad temperature spectrum, typically from -200°C to 260°C (-328°F to 500°F).

This makes them suitable for processes that involve cryogenic fluids as well as high-temperature operations, without becoming brittle or losing their structural integrity.

Exceptionally Low Friction

Teflon possesses one of the lowest coefficients of friction of any solid material, giving it self-lubricating and non-stick properties.

In dynamic applications with moving parts, this low friction reduces wear and tear on both the seal and the equipment. It also lowers the force needed for actuation in hydraulic and pneumatic systems.

Enhanced Durability and Longevity

Beyond its primary characteristics, PTFE is highly resistant to aging and environmental factors like UV radiation. This inherent durability translates to a long, reliable service life, reducing downtime and maintenance costs.

Understanding the Trade-offs

While Teflon's chemical and thermal properties are outstanding, it's crucial to understand its mechanical limitations to make an informed decision.

Mechanical Strength vs. Chemical Resistance

Standard PTFE is not as rigid or strong as some engineering plastics. Its primary advantage is its chemical inertness, not its raw mechanical strength.

In applications involving extremely high pressures but lacking aggressive chemicals, a material like PEEK (Polyetheretherketone) may be a better choice. PEEK offers superior strength and rigidity, providing greater resistance to extrusion in purely mechanical high-intensity systems.

Choosing Based on the Failure Risk

The material selection process should be guided by the most likely cause of failure.

If the primary risk is chemical attack or temperature degradation of the sealing system, Teflon is almost always the superior choice. If the risk is purely mechanical extrusion under immense pressure in a non-corrosive environment, a higher-strength material should be considered.

Making the Right Selection for Your System

Your final choice depends on the specific operational demands of your equipment.

- If your primary focus is resistance to aggressive chemicals: Teflon (PTFE) is the definitive choice for its unmatched inertness across acids, bases, and solvents.

- If your system operates across extreme temperatures: Teflon's wide temperature range ensures reliable performance from cryogenic lows to high-heat processes.

- If you need to minimize friction and wear in dynamic seals: Teflon's self-lubricating properties will protect moving components and extend the life of the system.

- If your main challenge is extreme pressure in a benign environment: Consider a higher-strength material like PEEK for maximum extrusion resistance.

Choosing the correct backup ring material is a critical step in designing a robust and reliable sealing system for any chemical processing application.

Summary Table:

| Advantage | Key Benefit | Ideal For |

|---|---|---|

| Chemical Inertness | Resists acids, bases, solvents | Acid treatment, chemical pipelines |

| Wide Temperature Range | Performs from -200°C to 260°C | Cryogenic fluids, high-heat processes |

| Low Friction | Self-lubricating, reduces wear | Dynamic seals, hydraulic/pneumatic systems |

| Durability | Resists aging, UV radiation | Long service life, reduced maintenance |

Need a reliable sealing solution for your harsh chemical process?

KINTEK specializes in manufacturing precision PTFE components, including custom backup rings, seals, liners, and labware. We understand the critical demands of the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your sealing systems are protected from aggressive media and extreme temperatures, enhancing integrity and extending service life.

Let us provide you with a solution tailored to your specific pressure, temperature, and chemical resistance requirements—from prototypes to high-volume production.

Contact KINTEK today for a custom quote and ensure your system's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications