In short, the sealing performance of PTFE gaskets provides unmatched reliability and safety in demanding industrial environments. By creating a durable, chemically inert barrier between connecting parts, they effectively prevent the leakage of liquids and gases, which in turn reduces costly maintenance, minimizes operational downtime, and ensures process integrity across a vast range of temperatures and pressures.

The core benefit of PTFE's sealing performance is not just its ability to prevent leaks, but its capacity to do so consistently under extreme chemical, thermal, and mechanical stress where most other materials would quickly degrade and fail.

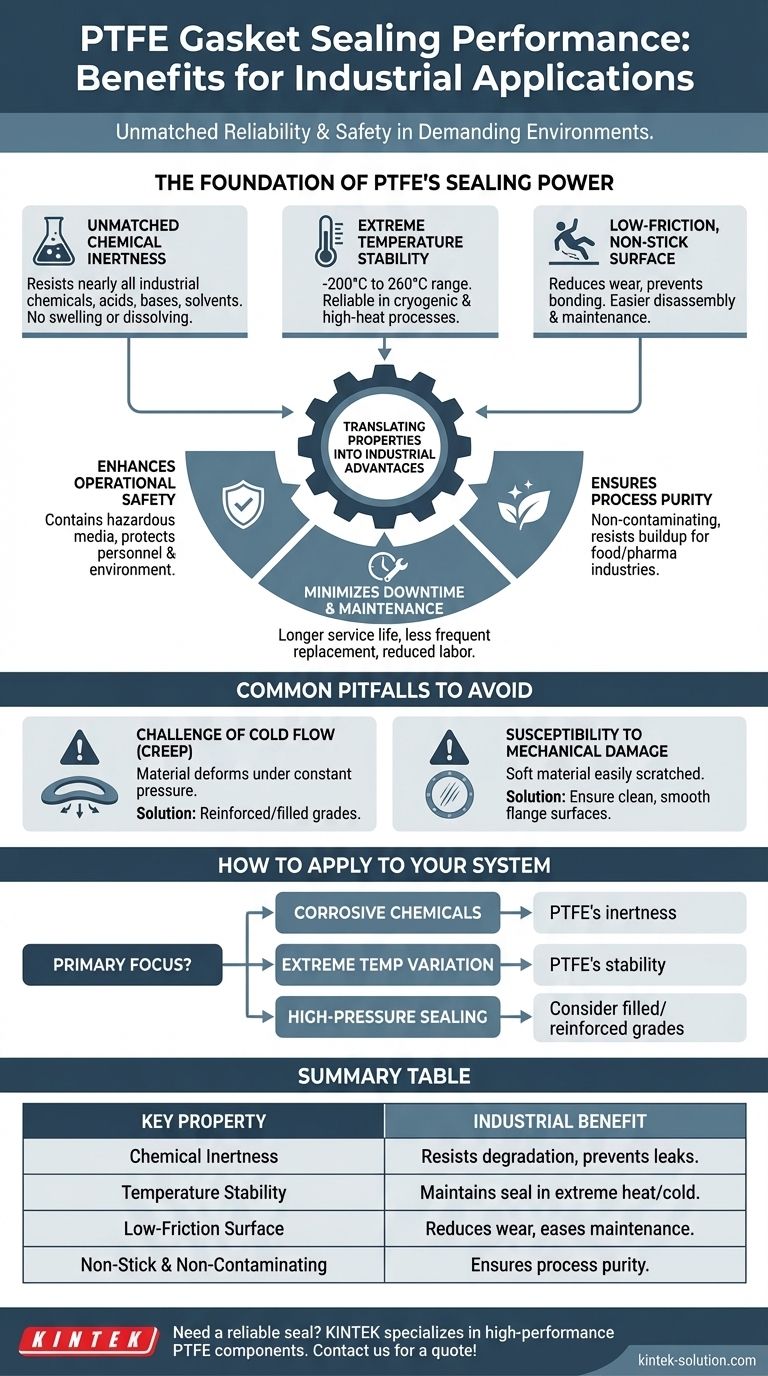

The Foundation of PTFE's Sealing Power

The exceptional sealing capability of Polytetrafluoroethylene (PTFE) is not a single feature but the result of several unique material properties working in concert. Understanding these fundamentals is key to appreciating its value.

Unmatched Chemical Inertness

PTFE is famously resistant to nearly all industrial chemicals, including strong acids, aggressive bases, and organic solvents.

This chemical stability ensures the gasket material does not swell, weaken, or dissolve when exposed to corrosive substances. This is critical for maintaining a secure seal and preventing catastrophic leaks in industries like chemical processing.

Extreme Temperature Stability

PTFE gaskets maintain their integrity and sealing properties across an exceptionally wide temperature range, typically from -200°C to 260°C (-328°F to 500°F).

This allows them to perform reliably in both cryogenic applications and high-temperature processes without becoming brittle or degrading, a versatility few other sealing materials can offer.

Low-Friction, Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material, creating a non-adhesive, "slippery" surface.

In dynamic sealing applications, this reduces wear and tear on moving parts. In static applications, it prevents the gasket from bonding to flange surfaces, making disassembly easier and reducing the risk of damage during maintenance.

Translating Properties into Industrial Advantages

These core properties deliver tangible benefits that directly impact operational efficiency, safety, and cost.

Enhancing Operational Safety

The primary function of any gasket is to prevent leaks. PTFE's resilience against harsh chemicals and extreme temperatures ensures it can safely contain hazardous or high-pressure media.

This reliability is fundamental to protecting personnel, preventing environmental contamination, and avoiding equipment failure.

Minimizing Downtime and Maintenance

Because PTFE gaskets do not easily degrade, they have a longer service life than many alternative materials.

This durability translates directly into less frequent replacement cycles, reduced maintenance labor, and minimized operational downtime, leading to significant cost savings over time.

Ensuring Process Purity

The inert and non-adhesive nature of PTFE is crucial in industries like food production and pharmaceuticals.

The gasket will not contaminate the process media, and its non-stick surface resists the buildup of materials, ensuring a clean and pure operational environment.

Common Pitfalls to Avoid

While highly effective, PTFE is not universally perfect. Understanding its limitations is critical for proper application and avoiding seal failure.

The Challenge of Cold Flow (Creep)

PTFE is a relatively soft material that can be subject to "cold flow" or "creep," where the material slowly deforms over time under constant pressure.

This can lead to a loss of bolt torque and a reduction in sealing pressure, potentially causing leaks. This is most prominent in high-temperature or high-pressure applications. Using reinforced or filled PTFE grades can help mitigate this issue.

Susceptibility to Mechanical Damage

The softness that allows PTFE to conform well to sealing surfaces also makes it susceptible to scratching or gouging during installation.

Care must be taken to ensure flange surfaces are clean and smooth. Any damage to the gasket surface can create a potential leak path.

How to Apply This to Your System

Choosing the right gasket depends entirely on the demands of your specific application.

- If your primary focus is handling corrosive chemicals: PTFE's unparalleled chemical inertness makes it the most reliable choice for ensuring seal integrity and longevity.

- If your primary focus is extreme temperature variation: PTFE's stability from cryogenic cold to high heat provides a consistent, dependable seal where other materials would fail.

- If your primary focus is high-pressure sealing: Standard PTFE is effective, but consider filled or reinforced grades to counteract cold flow and maintain sealing force.

By leveraging the unique properties of PTFE, you can engineer systems that are not only more efficient but fundamentally safer and more reliable.

Summary Table:

| Key Property | Industrial Benefit |

|---|---|

| Chemical Inertness | Resists virtually all industrial chemicals, preventing degradation and leaks. |

| Temperature Stability (-200°C to 260°C) | Maintains seal integrity in cryogenic and high-heat processes. |

| Low-Friction Surface | Reduces wear in dynamic seals and eases maintenance in static applications. |

| Non-Stick & Non-Contaminating | Ensures process purity for food, pharmaceutical, and semiconductor industries. |

Need a reliable seal for demanding conditions?

KINTEK specializes in manufacturing high-performance, precision PTFE components—including gaskets, seals, liners, and custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we deliver solutions that enhance safety, minimize downtime, and ensure process integrity.

From prototypes to high-volume orders, our custom fabrication expertise ensures a perfect fit for your application.

Contact KINTEK today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs