In short, the durability of Teflon sheets directly translates to higher quality, lower costs, and greater consistency in heat press printing operations. Because they can withstand high temperatures repeatedly without degrading, they provide a reliable protective barrier between your heat press, your transfer paper, and your final product.

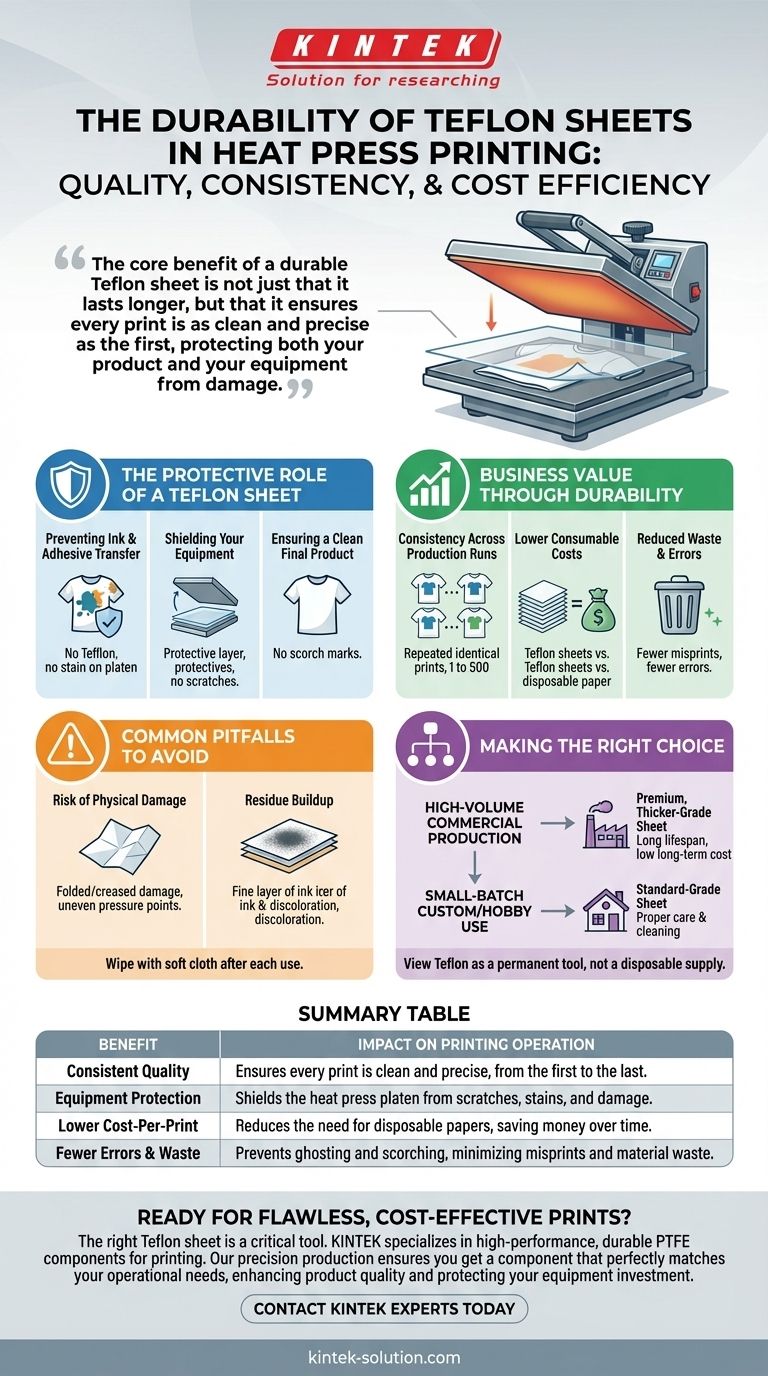

The core benefit of a durable Teflon sheet is not just that it lasts longer, but that it ensures every print is as clean and precise as the first, protecting both your product and your equipment from damage.

The Protective Role of a Teflon Sheet

In any heat press application, the goal is to transfer a design using heat and pressure. A Teflon sheet acts as an essential, reusable shield during this process.

Preventing Ink and Adhesive Transfer

The most well-known property of Teflon (PTFE) is its non-stick surface. During pressing, this prevents inks, vinyl, or adhesives from bleeding through the garment and staining the upper heating element (platen) of your press.

This is critical for preventing "ghosting," where remnants of a previous design are accidentally transferred to the next item.

Shielding Your Equipment

The upper platen of a heat press is a precision-machined, coated surface. A durable Teflon sheet acts as a protective barrier, preventing scratches and the buildup of ink or adhesive residue.

Protecting the platen is crucial for ensuring even heat distribution and extending the life of your machine, which is often a significant capital investment.

Ensuring a Clean Final Product

The sheet also protects the garment itself. It prevents direct contact with the hot metal platen, which can sometimes scorch or leave a sheen on certain fabrics. This ensures the final product is clean and professional.

How Durability Translates to Business Value

A sheet that withstands repeated use without failing provides tangible benefits that go straight to your bottom line.

Consistency Across Production Runs

A durable sheet does not degrade or warp under high heat. This means the 1st press of the day will have the same clean transfer and protection as the 500th press, ensuring predictable, high-quality results for every item.

Lower Consumable Costs

While a high-quality Teflon sheet has an upfront cost, its longevity makes it highly cost-efficient. A durable sheet can last for hundreds or even thousands of pressings, drastically reducing the cost-per-use compared to disposable parchment or butcher paper.

Reduced Waste and Errors

By preventing accidental ink transfers and protecting garments from scorching, a reliable Teflon sheet minimizes the number of misprints. This saves money on wasted materials, blank garments, and labor.

Common Pitfalls to Avoid

While highly durable, Teflon sheets are not indestructible. Understanding their limitations is key to maximizing their value.

The Risk of Physical Damage

A Teflon sheet's primary weakness is physical damage. Creases, folds, or scratches can create uneven pressure points during pressing, which may result in flawed transfers. Always store your sheets flat or loosely rolled.

The Problem of Residue Buildup

Over time, a fine layer of ink or adhesive vapor can build up on the sheet. While not always visible, this residue can cause discoloration on future prints, especially on white or light-colored fabrics.

Wiping the sheet with a soft cloth after each use is a simple but critical maintenance step to ensure its non-stick properties remain effective.

Making the Right Choice for Your Goal

Your operational needs should dictate your approach to using Teflon sheets.

- If your primary focus is high-volume commercial production: Invest in a premium, thicker-grade Teflon sheet to maximize its lifespan and ensure absolute consistency, lowering your long-term cost-per-print.

- If your primary focus is small-batch custom work or hobby use: A standard-grade sheet is perfectly adequate, but prioritize proper care and cleaning to extend its life and prevent costly printing errors.

Ultimately, viewing a durable Teflon sheet as a permanent tool rather than a disposable supply is fundamental to achieving professional-grade printing results.

Summary Table:

| Benefit | Impact on Printing Operation |

|---|---|

| Consistent Quality | Ensures every print is clean and precise, from the first to the last. |

| Equipment Protection | Shields the heat press platen from scratches, stains, and damage. |

| Lower Cost-Per-Print | Reduces the need for disposable papers, saving money over time. |

| Fewer Errors & Waste | Prevents ghosting and scorching, minimizing misprints and material waste. |

Ready to achieve flawless, cost-effective prints? The right Teflon sheet is a critical tool. At KINTEK, we specialize in manufacturing high-performance, durable PTFE components like Teflon sheets, seals, and liners for the printing, industrial, and specialized manufacturing sectors. Our precision production and custom fabrication services—from prototypes to high-volume orders—ensure you get a component that perfectly matches your operational needs, enhancing your product quality and protecting your equipment investment.

Contact our experts today to discuss your specific requirements and discover the KINTEK difference!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How is PTFE typically processed in manufacturing? A Guide to Molding, Sintering & Machining

- What are the properties of PTFE Lip Seals when blended with fillers? Enhance Performance for Demanding Seals

- What are the benefits of graphite-filled PTFE? Superior Self-Lubrication for Demanding Seals & Bearings

- What are the key features of encapsulated O-rings designed for chemical resistance? Achieve Superior Sealing in Harsh Environments

- What temperature range can PTFE coatings withstand? From -260°C to +260°C for Extreme Applications

- How do PTFE gaskets perform under long-term operation and cyclic loads? Ensure Reliable Sealing in Demanding Applications

- What are the advantages of using Teflon-coated bolts? Achieve Reliable Performance in Harsh Environments

- What types of PTFE processing machines are commonly used? From Extrusion to Precision Machining