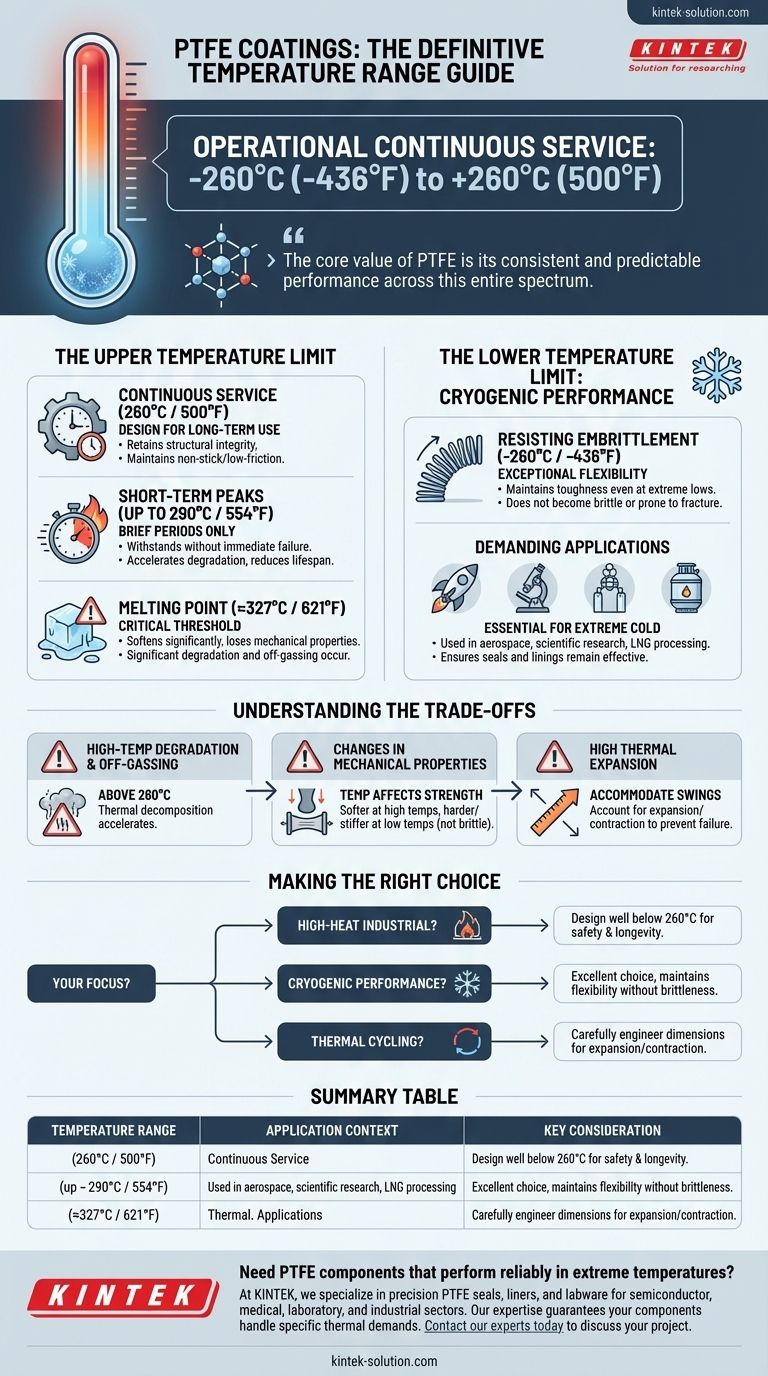

For a definitive answer, Polytetrafluoroethylene (PTFE) coatings operate reliably within a continuous service temperature range of approximately -260°C (-436°F) to +260°C (500°F). This exceptionally wide range makes PTFE one of the most versatile polymers for both extreme heat and cryogenic applications, where it maintains its critical properties without degradation.

The core value of PTFE is not just its tolerance for extreme temperatures, but its consistent and predictable performance across that entire spectrum. Unlike many materials that become brittle at low temperatures or degrade rapidly at high temperatures, PTFE remains stable and functional.

The Upper Temperature Limit

Understanding the high-temperature behavior of PTFE is crucial for ensuring component longevity and safety. The limits are best understood as distinct thresholds for different exposure times.

The Continuous Service Temperature

The most cited and widely accepted maximum continuous operating temperature for PTFE is 260°C (500°F).

Engineers should design systems for long-term use around this figure to ensure the material retains its structural integrity and signature non-stick and low-friction properties.

Short-Term Exposure Peaks

For very brief periods, PTFE can withstand temperatures up to 290°C (554°F) without immediate failure.

However, operating near or above the continuous service limit for any extended time will accelerate material degradation and reduce its operational lifespan.

The Critical Melting Point

PTFE has a high melting point of approximately 327°C (621°F).

It is critical to note that long before it melts, the material will begin to soften and lose its mechanical properties. Significant degradation and off-gassing can occur as it approaches this temperature.

The Lower Temperature Limit: Cryogenic Performance

PTFE's performance at extremely low temperatures is just as impressive as its heat resistance. It is a preferred material for cryogenic systems where other plastics and elastomers would fail.

Resisting Embrittlement

Many materials become extremely brittle and prone to fracture at cryogenic temperatures.

PTFE is exceptional in that it maintains a high degree of flexibility and toughness even at temperatures as low as -260°C (-436°F), with some data showing stability down to -270°C (-454°F).

Why This Matters for Demanding Applications

This resistance to cold-induced brittleness makes PTFE essential for components in aerospace, scientific research, and liquefied natural gas (LNG) processing.

It ensures that seals, gaskets, and linings remain effective and do not fail under the stress of extreme cold.

Understanding the Trade-offs

While its temperature range is vast, designing with PTFE requires an understanding of its behavior at the extremes. It is not an infinitely perfect material.

High-Temperature Degradation and Off-Gassing

As PTFE approaches its upper continuous service limit, it can begin to release fumes.

Operating consistently above 260°C (500°F) is not recommended, as this thermal decomposition accelerates and can impact safety and material performance.

Changes in Mechanical Properties

Temperature affects PTFE's mechanical strength. At higher temperatures, it becomes softer and more susceptible to creep and deformation under load.

Conversely, at cryogenic temperatures, it becomes harder and stiffer, though it does not become brittle. These changes must be accounted for in engineering design.

High Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion compared to metals.

In applications with wide temperature swings, designers must account for the material's expansion and contraction to maintain proper clearances and prevent component failure.

Making the Right Choice for Your Application

Use these guidelines to determine if PTFE's thermal properties align with your project's specific demands.

- If your primary focus is high-heat industrial use: Design for continuous operation well below the 260°C (500°F) limit to guarantee a long service life and a significant safety margin.

- If your primary focus is cryogenic performance: PTFE is an excellent choice, as it will maintain its flexibility and sealing capabilities without becoming brittle at extreme lows.

- If your primary focus is thermal cycling: Carefully engineer component dimensions to accommodate PTFE's high thermal expansion and contraction across your operational temperature range.

Ultimately, PTFE's remarkable thermal stability provides a reliable solution for the most demanding temperature environments.

Summary Table:

| Temperature Range | Application Context | Key Consideration |

|---|---|---|

| -260°C to +260°C | Continuous Service | Maintains flexibility and non-stick properties. |

| Up to +290°C | Short-Term Peak Exposure | Accelerated degradation possible; not for long-term use. |

| Near +327°C | Melting Point | Material softens and off-gassing occurs; avoid this range. |

Need PTFE components that perform reliably in extreme temperatures?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your components are engineered to handle your specific thermal demands, providing the durability and safety margins your application requires.

Contact our experts today to discuss your project's temperature challenges and find the perfect PTFE solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What is the first step in both PTFE production methods? Unlocking the Key to High-Performance Polymer Manufacturing

- What are the main differences between virgin Teflon balls and glass-filled Teflon balls? Choose the Right PTFE for Your Application

- What are the process advantages of machining Teflon? High-Speed Production with Superior Thermal Stability

- What pressure can ePTFE gaskets withstand? Understanding Their True Capabilities

- What advantages do PTFE coatings offer in terms of durability and maintenance? Maximize Component Lifespan

- What are the advantages of molybdenum disulfide-filled PTFE? Boost Wear Resistance & Reduce Friction

- What standards and compliance measures are followed in manufacturing Teflon parts? Ensuring Quality from ISO to Final Inspection

- What is PTFE used for in bearing bushings? To enable self-lubrication in extreme environments.