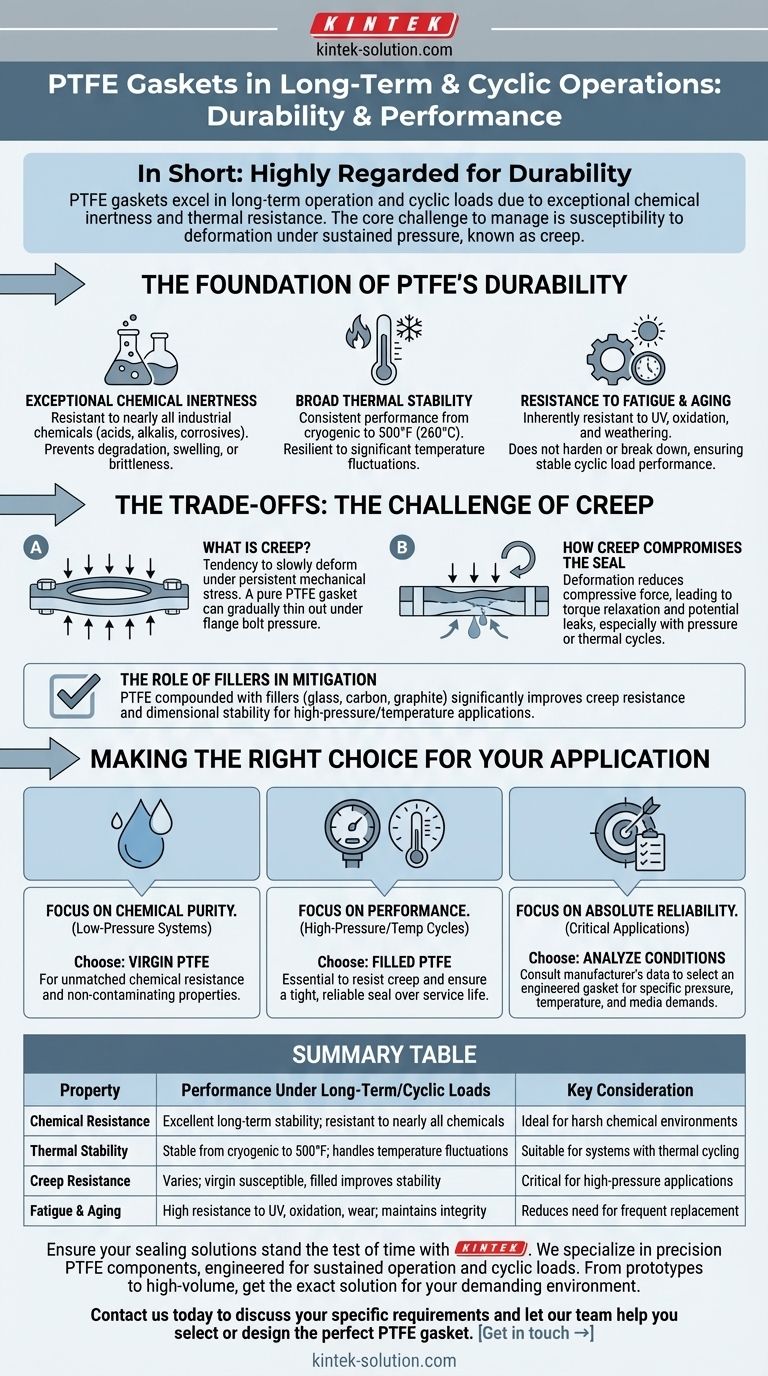

In short, PTFE gaskets are highly regarded for their durability under long-term operation and cyclic loads. Their exceptional chemical inertness and resistance to temperature extremes allow them to maintain stable performance and reliable sealing over extended periods, even in harsh and complex environments.

The core consideration for PTFE's long-term performance is its physical response to pressure. While its chemical and thermal stability is world-class, its susceptibility to deformation under sustained load—a phenomenon known as creep—is the critical factor that must be managed for success in demanding applications.

The Foundation of PTFE's Durability

Polytetrafluoroethylene (PTFE) possesses a unique combination of properties that make it a default choice for many long-term sealing applications. These characteristics provide a baseline of exceptional stability.

Exceptional Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, including aggressive acids, alkalis, and corrosive substances. This prevents the material from degrading, swelling, or becoming brittle over time due to chemical attack.

This inertness ensures the gasket maintains its integrity and sealing capability, providing reliable service in complex chemical environments without contamination or failure.

Broad Thermal Stability

PTFE gaskets perform consistently across an extremely wide temperature range. They can maintain their properties without melting or burning at temperatures as high as 500°F (260°C) and remain functional in cryogenic conditions.

This thermal resilience makes them suitable for demanding systems involving steam, high-powered engines, and other processes with significant temperature fluctuations.

Resistance to Fatigue and Aging

Unlike many elastomers, PTFE is inherently resistant to aging from UV light, oxidation, and weathering.

This, combined with its excellent wear and fatigue resistance, means the material does not harden or break down over time, ensuring a stable and predictable performance life under many cyclic loads.

Understanding the Trade-offs: The Challenge of Creep

While chemically robust, PTFE's primary mechanical limitation is its tendency to deform under pressure, a behavior often called creep or cold flow.

What is Creep?

Creep is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stress. For a gasket, this means it can be slowly squeezed out of the flange over time.

When subjected to high external pressure from flange bolts, a pure PTFE gasket can gradually deform, thinning out in the compressed area.

How Creep Compromises the Seal

This deformation can compromise sealing performance. As the gasket thins, the initial bolt torque relaxes, reducing the compressive force on the mating surfaces.

This loss of sealing stress can eventually lead to leaks, especially in systems with pressure or thermal cycles that can exacerbate the effect.

The Role of Fillers in Mitigation

To combat creep, PTFE is often compounded with filler materials like glass, carbon, or graphite. These fillers act as a reinforcing matrix within the PTFE.

Gaskets with a higher filler content provide significantly improved resistance to creep and maintain better dimensional stability, especially in high-temperature or high-pressure applications.

Making the Right Choice for Your Application

Selecting the correct type of PTFE gasket is crucial and depends entirely on matching the material's properties to the system's operating conditions.

- If your primary focus is chemical purity in a low-pressure system: Virgin (unfilled) PTFE is an excellent choice for its unmatched chemical resistance and non-contaminating properties.

- If your primary focus is performance under high pressure or temperature cycles: A filled PTFE gasket is essential to resist creep and ensure the seal remains tight and reliable over its service life.

- If your primary focus is absolute reliability in a critical application: Always analyze the full operating conditions—pressure, temperature, and media—and consult the manufacturer's data to select a gasket specifically engineered to handle those demands.

By understanding both the inherent strengths and the mechanical limitations of PTFE, you can confidently select the right material to ensure reliable, long-term sealing performance.

Summary Table:

| Property | Performance Under Long-Term/Cyclic Loads | Key Consideration |

|---|---|---|

| Chemical Resistance | Excellent long-term stability; resistant to nearly all industrial chemicals | Ideal for harsh chemical environments |

| Thermal Stability | Stable from cryogenic to 500°F (260°C); handles temperature fluctuations | Suitable for systems with thermal cycling |

| Creep Resistance | Varies by formulation; virgin PTFE susceptible, filled PTFE (glass, carbon) improves stability | Critical for high-pressure applications |

| Fatigue & Aging | High resistance to UV, oxidation, and wear; maintains integrity over time | Reduces need for frequent replacement |

Ensure your sealing solutions stand the test of time with KINTEK.

PTFE gaskets are crucial for long-term reliability in semiconductor, medical, laboratory, and industrial applications. At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—that are engineered to perform under sustained operation and cyclic loads. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get the exact solution for your demanding environment.

Contact us today to discuss your specific requirements and let our team help you select or design the perfect PTFE gasket for unparalleled durability and performance. Get in touch →

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments