Ultimately, the corrosion resistance of PTFE fasteners is a cornerstone of medical device safety and reliability. This property ensures that fasteners maintain their structural integrity and do not degrade or release contaminants when exposed to the aggressive chemicals and sterilization processes common in healthcare environments.

The core benefit is simple: PTFE's profound chemical inertness prevents it from reacting with its environment. In a medical setting, this means a fastener that will not corrode, weaken, or contaminate, directly contributing to equipment longevity and patient safety.

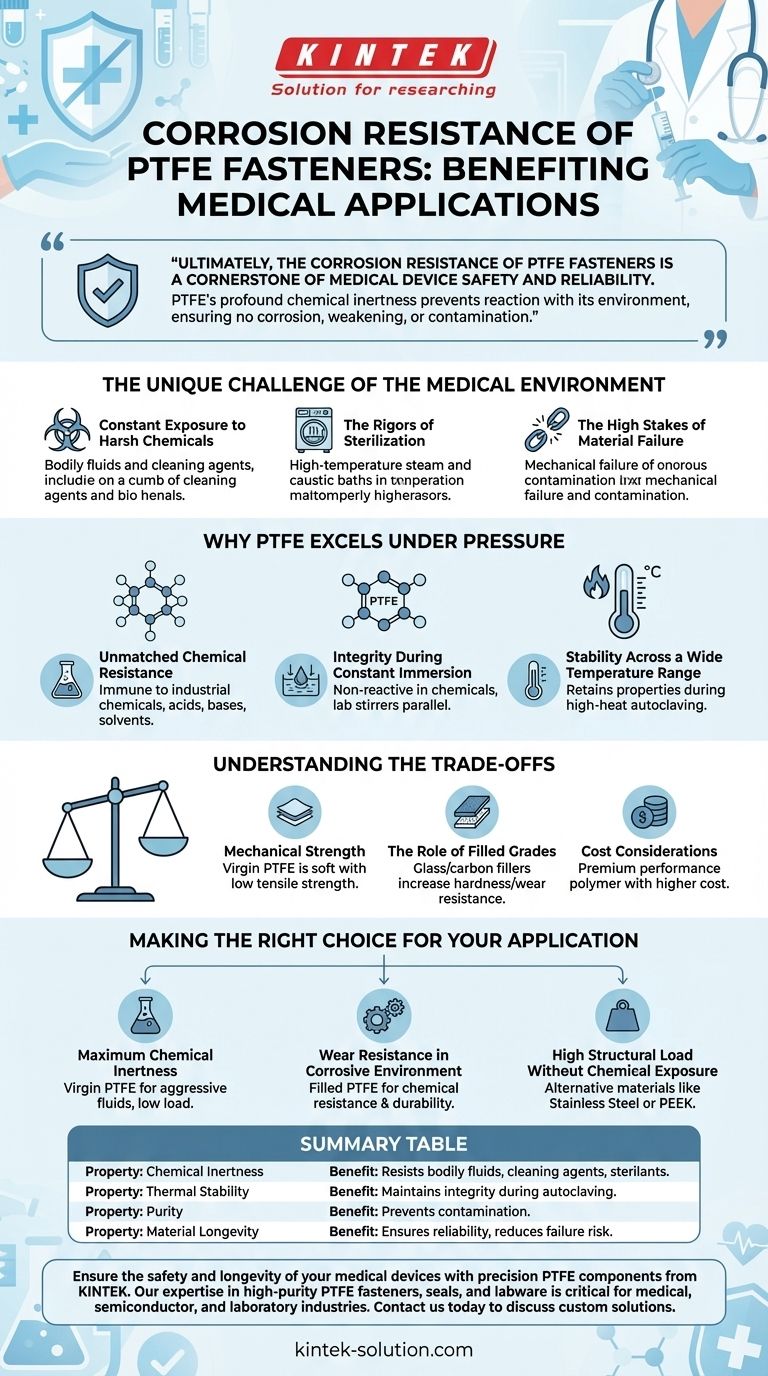

The Unique Challenge of the Medical Environment

Traditional materials often fail when subjected to the demanding conditions of medical and laboratory settings. The environment is inherently hostile to many metals and plastics, creating a need for exceptionally resilient components.

Constant Exposure to Harsh Chemicals

Medical equipment is constantly exposed to a wide array of substances, including bodily fluids, aggressive cleaning agents, and sterilizing chemicals. These can quickly corrode standard materials, compromising the device.

The Rigors of Sterilization

Sterilization processes, whether using high-temperature steam in an autoclave or caustic chemical baths, are designed to destroy organic matter. Unfortunately, they are also highly corrosive to many materials, causing them to degrade over time.

The High Stakes of Material Failure

In a medical context, the failure of a simple component like a fastener can have severe consequences. A corroded fastener can lead to mechanical failure of a device or introduce harmful contaminants into a sterile field.

Why PTFE Excels Under Pressure

Polytetrafluoroethylene (PTFE) possesses a unique molecular structure that makes it one of the most non-reactive substances known. This chemical inertness is the key to its performance in corrosive applications.

Unmatched Chemical Resistance

PTFE is virtually immune to almost all industrial chemicals, acids, bases, and solvents. This ensures that fasteners made from PTFE will not be damaged by sterilizing agents or other aggressive fluids they encounter.

Integrity During Constant Immersion

As seen in laboratory equipment like stirrers, PTFE can be constantly immersed in chemicals without reacting or degrading. This is a direct parallel to medical components that are part of fluid paths or require frequent, intensive cleaning.

Stability Across a Wide Temperature Range

PTFE retains its essential properties across a broad spectrum of temperatures. This makes it perfectly suited for devices that must endure the high heat of autoclaving and other thermal sterilization methods.

Understanding the Trade-offs

While its chemical resistance is nearly absolute, PTFE is not a universal solution. An objective evaluation requires acknowledging its limitations.

Mechanical Strength

Virgin PTFE is a relatively soft material with low tensile strength compared to metals or other engineering plastics. It is not suitable for high-load, structural applications on its own.

The Role of Filled Grades

To overcome mechanical weaknesses, PTFE can be blended with fillers like glass or carbon. These filled PTFE grades significantly increase hardness and wear resistance, making them suitable for more demanding mechanical roles, but this can alter other properties.

Cost Considerations

PTFE is a premium performance polymer. Its cost is higher than that of common plastics and many metals, making it a choice reserved for applications where its unique properties are a critical requirement.

Making the Right Choice for Your Application

Selecting the right fastener material depends entirely on the specific demands of the device and its intended use.

- If your primary focus is maximum chemical inertness: Virgin PTFE is the ideal choice for components in direct contact with aggressive fluids or subject to harsh sterilization where mechanical load is low.

- If your primary focus is wear resistance in a corrosive environment: A glass-filled or carbon-filled PTFE fastener offers an excellent balance of chemical resistance and enhanced mechanical durability.

- If your primary focus is high structural load without chemical exposure: A different material, such as stainless steel or another engineering polymer like PEEK, would likely be a more appropriate and cost-effective choice.

By understanding these distinct properties, you can select a material that ensures the safety, reliability, and longevity of critical medical technology.

Summary Table:

| Property | Benefit for Medical Applications |

|---|---|

| Chemical Inertness | Resists bodily fluids, cleaning agents, and sterilants without degrading. |

| Thermal Stability | Maintains integrity during autoclaving and other high-temperature sterilization. |

| Purity | Prevents contamination of sterile fields and fluid paths. |

| Material Longevity | Ensures device reliability and reduces the risk of component failure. |

Ensure the safety and longevity of your medical devices with precision PTFE components from KINTEK.

Our expertise in manufacturing high-purity PTFE fasteners, seals, and labware is critical for applications in the medical, semiconductor, and laboratory industries. Whether you need virgin PTFE for maximum chemical resistance or filled grades for enhanced mechanical properties, we provide custom fabrication from prototypes to high-volume orders.

Contact us today to discuss how our PTFE solutions can benefit your specific application and contribute to your product's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials