Choosing the right PTFE Expansion Bellow is a critical engineering decision that directly enhances system efficiency, minimizes operational risks, and significantly reduces long-term maintenance costs. By correctly matching the bellow to the system's specific demands, you ensure its long-term reliability and integrity, especially in harsh industrial environments.

The core function of a PTFE expansion bellow is not merely to connect pipes, but to act as a flexible, protective joint that absorbs the destructive forces of movement, vibration, and thermal stress. Selecting the right one transforms it from a simple component into a crucial asset for system longevity and safety.

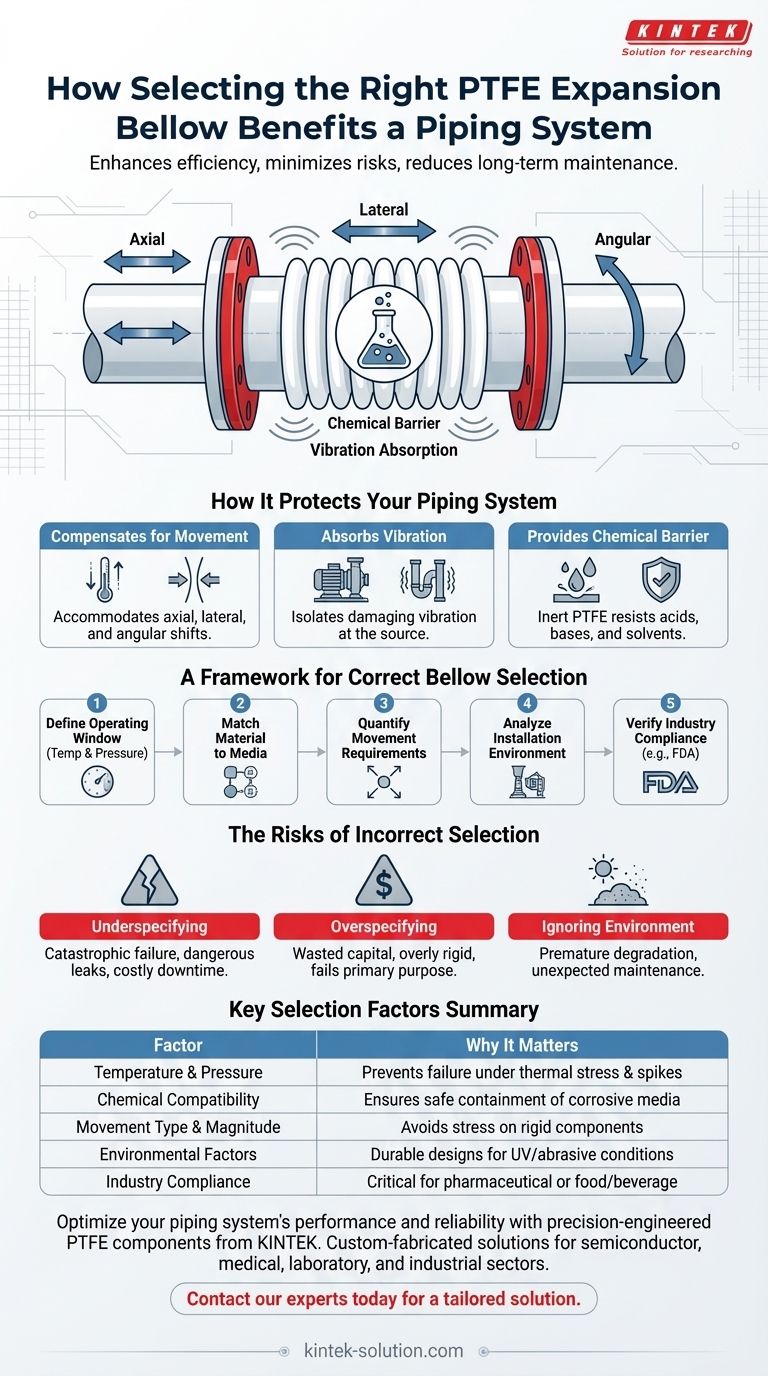

How a Bellow Protects Your Piping System

A PTFE expansion bellow is a specialized flexible connector engineered to solve specific physical challenges within a pipeline. Its proper application prevents premature failure of the entire system.

Compensates for Inevitable Movement

Piping systems are rarely static. Temperature fluctuations cause pipes to expand and contract (thermal expansion), and settling or initial installation can create minor misalignments.

A correctly specified bellow accommodates these axial (in-line), lateral (sideways), and angular movements without transferring stress to more rigid components like pump nozzles or vessel connections.

Absorbs Destructive Vibration

Machinery such as pumps, compressors, and engines introduce constant vibration into a piping system. Over time, this energy can weaken joints and cause fatigue fractures.

The bellow acts as a dampener, isolating the vibration at its source and protecting the rest of the pipeline from its damaging effects.

Provides a Chemically Inert Barrier

PTFE is renowned for its exceptional chemical resistance to most acids, bases, and solvents. This makes it an ideal material for systems handling corrosive fluids.

The bellow ensures that aggressive media is safely contained, preventing leaks and corrosion that would compromise standard piping materials.

A Framework for Correct Bellow Selection

Choosing the right bellow requires a systematic evaluation of its operating environment. Overlooking any single factor can lead to premature failure.

Define the Operating Window: Temperature and Pressure

The bellow's specified temperature and pressure ratings must comfortably exceed the system's maximum operating conditions. PTFE is effective across a vast range, typically from -200°C to 260°C, but these limits can be affected by pressure.

Match the Material to the Media

While PTFE is highly resistant, you must confirm its compatibility with the specific chemicals flowing through the system, especially at operating temperatures. This is the first line of defense against chemical degradation.

Quantify the Movement Requirements

You must identify the exact types and magnitudes of movement the bellow needs to absorb. Is the primary challenge thermal growth (axial movement) or pump vibration (lateral movement)? An undersized bellow will fail under stress.

Analyze the Installation Environment

External factors can impact the bellow's lifespan. Consider exposure to UV radiation if installed outdoors, or the presence of abrasive materials in the atmosphere. These conditions may require specialized bellow covers or materials.

Verify Industry Compliance

For industries like pharmaceuticals or food and beverage, components must meet strict hygienic standards. Ensure the bellow and its materials comply with necessary certifications, such as FDA or ISO standards.

The Risks of Incorrect Selection

Choosing the wrong expansion bellow is not a minor error; it introduces significant financial and safety risks into your operation.

The Danger of Underspecifying

Selecting a bellow with insufficient pressure, temperature, or movement ratings is a direct path to catastrophic failure. A rupture can cause dangerous leaks, costly downtime, and potential harm to personnel.

The Hidden Cost of Overspecifying

While less dangerous, choosing a bellow that is far more robust than necessary leads to wasted capital. More importantly, an overly rigid or complex bellow may not provide the required flexibility, negating its primary purpose.

Ignoring Environmental Factors

A standard bellow installed in an environment with high UV exposure or abrasive dust will degrade far more quickly than one designed for those conditions. This leads to unexpected maintenance cycles and unplanned shutdowns.

Making the Right Choice for Your Goal

Your final selection should be guided by the most critical demand of your specific application.

- If your primary focus is handling corrosive chemicals: Prioritize verification of chemical compatibility at your system's operating temperature and pressure.

- If your primary focus is a high-vibration mechanical system: Ensure the bellow is explicitly rated to absorb the specific frequency and amplitude of the vibration produced by your equipment.

- If your primary focus is a hygienic or sanitary process: Confirm that the bellow holds all required certifications (e.g., FDA) and is designed for clean-in-place (CIP) procedures if necessary.

- If your primary focus is managing thermal expansion: Your most important data points will be the pipe material, length, and the minimum/maximum temperature range to calculate the total required axial movement.

Ultimately, a well-chosen PTFE expansion bellow is an investment in the fundamental stability and safety of your entire piping system.

Summary Table:

| Key Selection Factor | Why It Matters |

|---|---|

| Temperature & Pressure | Must exceed system max to prevent failure under thermal stress and pressure spikes. |

| Chemical Compatibility | PTFE resists acids, bases, and solvents, ensuring safe containment of corrosive media. |

| Movement Type & Magnitude | Accommodates axial, lateral, and angular movements to avoid stress on rigid components. |

| Environmental Factors | UV exposure or abrasive conditions may require specialized bellow designs for durability. |

| Industry Compliance | Certifications like FDA or ISO are critical for pharmaceutical or food/beverage applications. |

Optimize your piping system's performance and reliability with precision-engineered PTFE components from KINTEK.

Whether you're in the semiconductor, medical, laboratory, or industrial sector, our custom-fabricated PTFE expansion bellows are designed to handle your specific challenges—from corrosive chemicals and extreme temperatures to high-vibration environments. We specialize in creating solutions that enhance system longevity, from initial prototypes to high-volume production.

Contact our experts today to discuss your application requirements and receive a tailored solution that ensures safety, efficiency, and cost savings.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What materials are used in Teflon encapsulation for O-rings? A Guide to FEP & PFA Jackets

- How does the low coefficient of friction of PTFE balls benefit their use in valves and pumps? Enhance Efficiency and Reliability

- How do spring-energized PTFE seals perform in high-pressure environments? Unlock Superior Sealing Reliability

- What temperature range can PTFE seals and rings operate within? Withstand -200°C to +260°C Extremes

- What benefits do fillers provide for PTFE lip seals? Enhance Wear, Pressure, and Thermal Performance

- Why is PTFE resistant to chemicals? The Science Behind Its Unmatched Inertness

- How do PTFE expansion joints contribute to sustainability? Enhance Long-Term System Integrity & Environmental Safety

- What are the benefits of PTFE butterfly valves in industrial applications? Enhance Safety, Purity & Efficiency